Hydrothermal synthesizing method of sheet-formed diindium trisulphide nano-structured material

A technology of indium trisulfide and indium trichloride tetrahydrate, which is applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of complex reaction conditions, excessively high reaction temperature, long reaction time, etc. The effect of simplicity, high product purity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

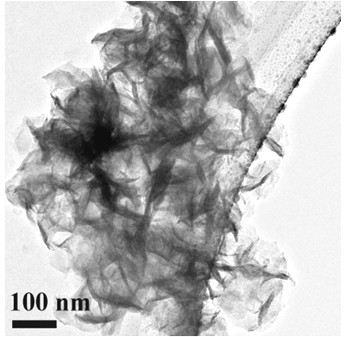

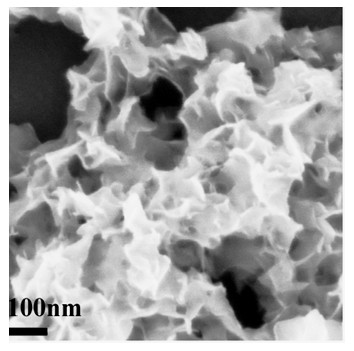

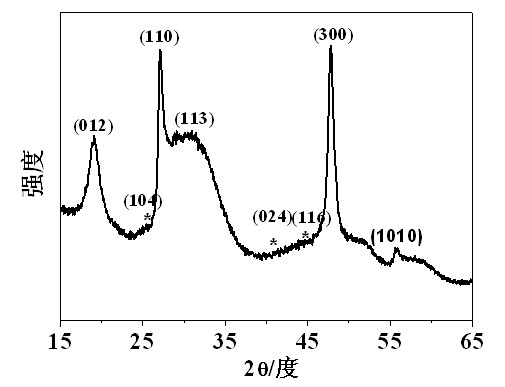

[0029] Follow the preparation process. Add 0.231g of indium trichloride tetrahydrate into a beaker containing 25ml of deionized water, and stir magnetically for 7 minutes to obtain a transparent and clear solution; add 260mg of hexadecyltrimethylammonium bromide and continue to stir for 10 minutes; When the solution was still clear, 178 mg of thioacetamide was finally added and magnetically stirred for 13 minutes to obtain a pale yellow solution, which was used as a reaction precursor. The solution was poured into a 100ml three-necked round-bottomed flask, and placed in a reaction heating system with reflux to keep the temperature constant. The reaction conditions were: 95°C, 80min. After the reaction, the solution was centrifuged at a centrifugal rate of 10000r / min for 15min. After repeated centrifugation for 5 times, the solid obtained was vacuum-dried at room temperature into a powder. The transmission electron microscope test sample is to take out a small amount of the s...

Embodiment 2

[0031] Follow the preparation process. Add 0.231g of indium trichloride tetrahydrate into a beaker containing 25ml of deionized water, and stir magnetically for 7 minutes to obtain a transparent and clear solution; add 260mg of hexadecyltrimethylammonium bromide and continue to stir for 10 minutes; When the solution was still clear, 178 mg of thioacetamide was finally added and magnetically stirred for 13 minutes to obtain a pale yellow solution, which was used as a reaction precursor. The solution was poured into a 100ml three-neck round bottom flask, and placed in a reaction heating system with reflux to keep the temperature constant. The reaction conditions were: 80°C, 80min. After the reaction, the solution was centrifuged at a centrifugal rate of 10000r / min for 15min. After repeated centrifugation for 5 times, the solid obtained was vacuum-dried at room temperature into a powder. The transmission electron microscope test sample is to take out a small amount of the solid...

Embodiment 3

[0033] Follow the preparation process. Add 0.231g of indium trichloride tetrahydrate into a beaker containing 25ml of deionized water, and stir magnetically for 7 minutes to obtain a transparent and clear solution; then add 178mg of thioacetamide and stir magnetically for 13 minutes to obtain a light yellow solution. The solution acts as a precursor for the reaction. The solution was poured into a 100ml three-necked round-bottomed flask, and placed in a reaction heating system with reflux to keep the temperature constant. The reaction conditions were: 95°C, 80min. After the reaction, the solution was centrifuged at a centrifugal rate of 10000r / min for 15min. After repeated centrifugation for 5 times, the solid obtained was vacuum-dried at room temperature into a powder. The transmission electron microscope test sample is to take out a small amount of the solid powder obtained after drying and redisperse it in absolute ethanol, and use a pipette gun to suck two drops on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com