Phosphorus-containing flame retardant with fluorenyl groups and preparation method thereof

A flame retardant, fluorene-based technology, applied in the field of chemical materials, can solve the problem of no relevant reports, and achieve the effects of wide application range, good heat resistance and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Add calcium-type A molecular sieve (5g) into the bottles containing dimethylformamide (473g) and triethylamine (328g) respectively, and use them one day later.

[0029] 2) Dissolve 0.01mol of bisphenol fluorene in 13ml of dimethylformamide, transfer it into a three-neck flask, seal it at 25°C, stir it evenly with magnetic force, add 0.025mol of triethylamine, and continue stirring.

[0030] 3) Add 0.01 mol of phenylphosphonic acid dichloride dissolved in 13 ml of dimethylformamide dropwise at 25°C, keep the system closed and magnetically stirred, and the dropwise addition is completed in 5 minutes.

[0031] 4) Seal and keep warm at 25°C for 1 hour.

[0032] 5) Use a rotary evaporator to remove most of the solvent in the system, and adjust the pH to 6-7 with 0.1mol / L hydrochloric acid. Washing with water for 3 to 5 times, washing with methanol for 3 to 5 times, and drying to obtain polyphenyl phosphonic acid bisphenol fluorene ester.

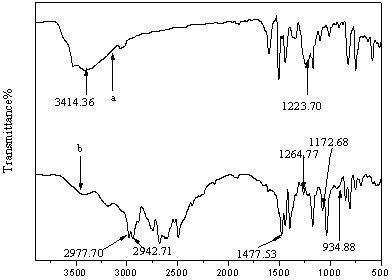

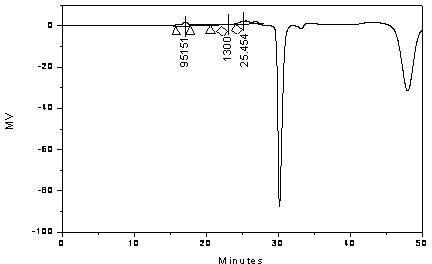

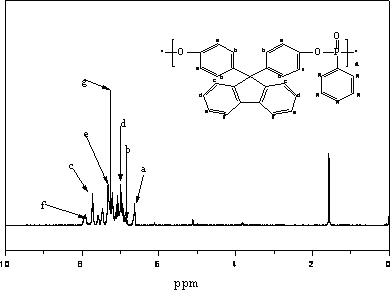

[0033] The results of its infr...

Embodiment 2

[0036] 1) Add calcium-type A molecular sieve (5g) into the bottles containing tetrahydrofuran (445g) and triethylamine (328g) respectively, and use them one day later.

[0037] 2) Dissolve 0.01mol of bisphenol fluorene in 13ml of tetrahydrofuran, transfer it into a three-necked flask, seal it at 25°C, stir it evenly with a magnetic force, add 0.025mol of triethylamine, and continue stirring.

[0038] 3) 0.01 mol of phenylphosphonic dichloride dissolved in 13 ml of tetrahydrofuran was added dropwise at 0°C, and the system was kept closed with magnetic stirring, and the dropwise addition was completed in 60 minutes.

[0039] 4) Seal and keep warm at 25°C for 1 hour.

[0040] 5) Use a rotary evaporator to remove most of the solvent in the system, and adjust the pH to 6-7 with 0.1mol / L hydrochloric acid. Washing with water for 3 to 5 times, washing with methanol for 3 to 5 times, and drying to obtain polyphenyl phosphonic acid bisphenol fluorene ester.

[0041] Its structural ch...

Embodiment 3

[0043] The synthesis steps were carried out according to Example 1, except that the triethylamine in Example 1 (steps (1) and (2) in Example 1) was replaced by pyridine to obtain polyphenylphosphonic acid bisphenol fluorene ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com