Method for treating high salinity and high consistency industrial wastewater to realize waste control by waste

A technology for industrial waste water and waste treatment, which is applied in energy waste water treatment, water/sewage treatment, general water supply conservation, etc. It can solve the problems of not being able to ensure the low operating cost of waste water and meet the discharge standards, so as to improve the biochemical performance and BC ratio, detoxification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

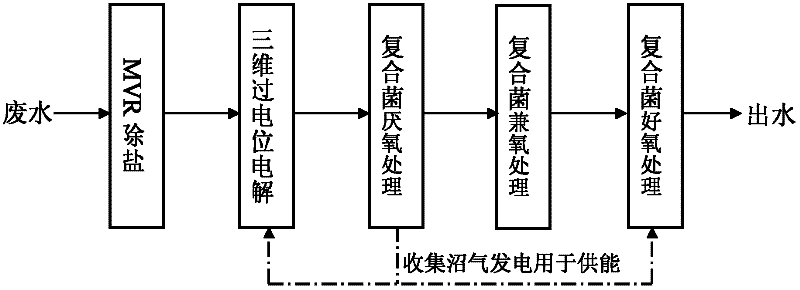

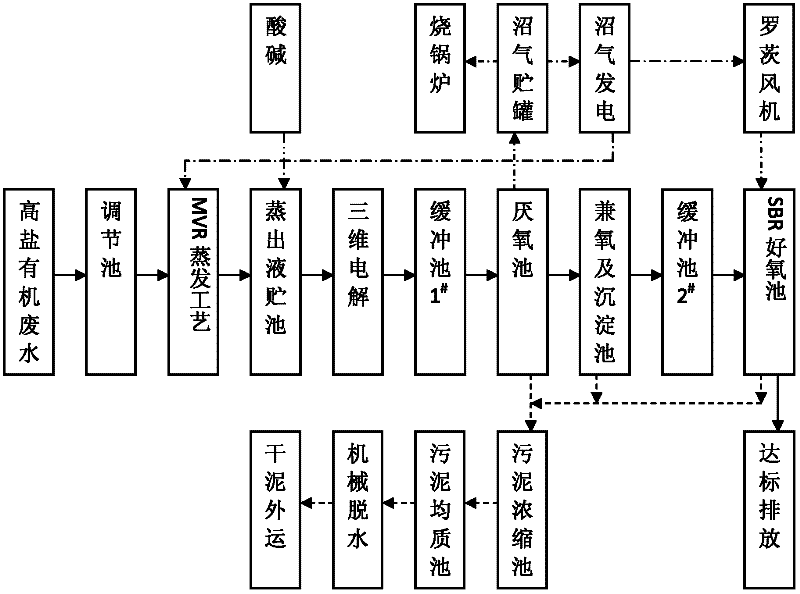

[0038] In this example, the waste water of pharmaceutical intermediates and fine chemical industry, which have high concentration of organic pollutants, high salinity, high ammonia nitrogen, and complex pollutant components, are difficult to treat, and adopt MVR evaporation process, three-dimensional overpotential electrolysis, and high-efficiency composite bacteria. The biochemical process treats and collects the biogas for power generation to feed the above mentioned processes.

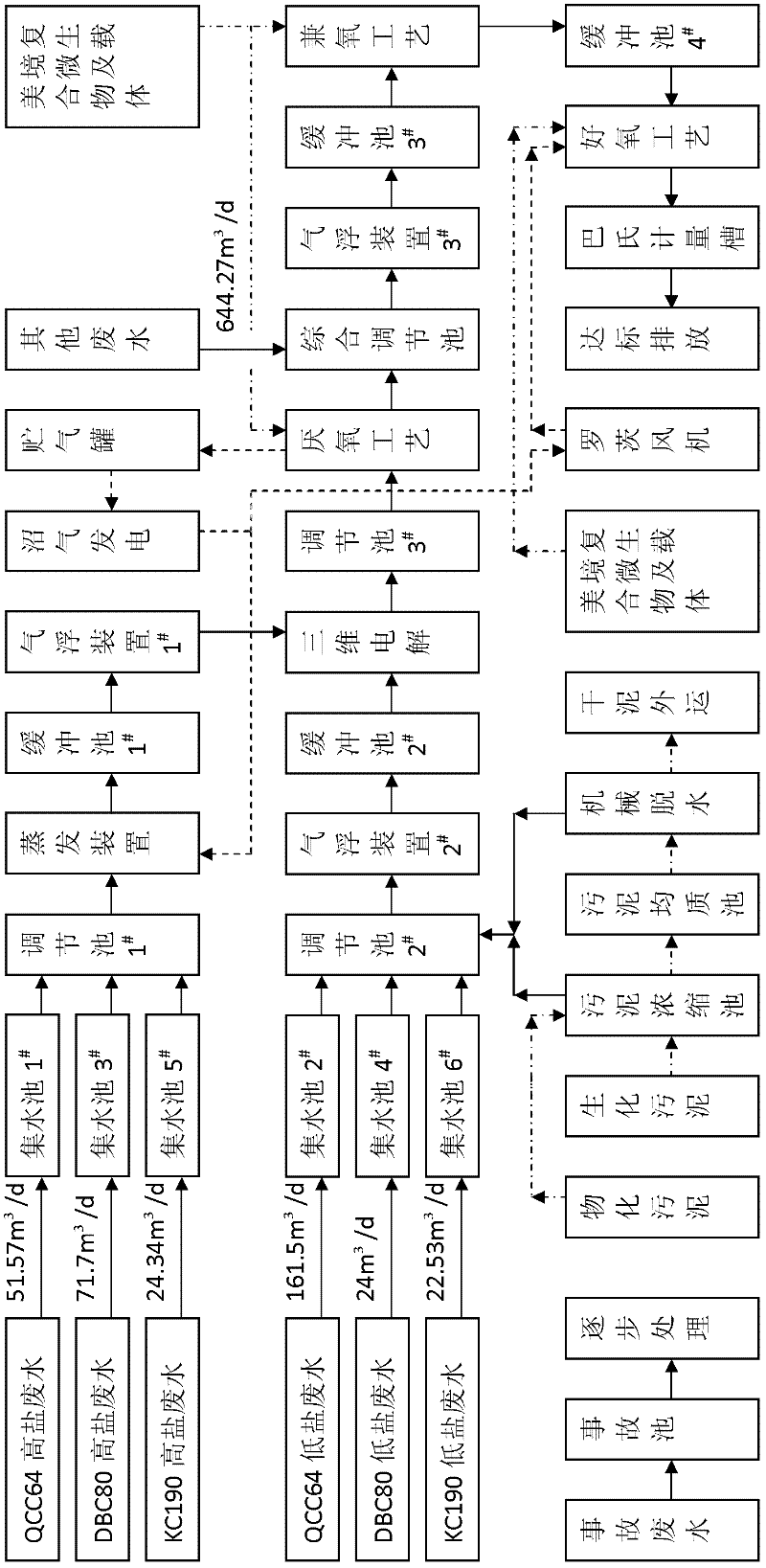

[0039] (1) Processing objects:

[0040] The treatment object is the production wastewater from the workshop of a chemical company in Shanghai, including: high-salt wastewater (QCC64, KC190, DBC80), low-salt wastewater (QCC64, KC190, DBC80), other wastewater, their water quality is shown in the table 1. These wastewaters are composed of different production wastewaters, as shown in Table 2 and 3 for details.

[0041] Table 1. Water Quality and Quantity of Treated Wastewater

[0042]

[0043] Ta...

Embodiment 2

[0060] 1 Overview

[0061] A pilot test was carried out on the pesticide wastewater of a Jiangsu Green Chemical Co., Ltd.

[0062] 2.1 Test water quality

[0063] The specific water quality of pesticide wastewater is shown in Table 5.

[0064] Table 5. Water quality of pesticide wastewater

[0065]

[0066] 2.2 Test device and scale

[0067] One set of evaporation device, with a processing capacity of 4L per batch; one set of partial dissolved air flotation device, with a processing capacity of 5L per batch; one set of overpotential three-dimensional electrolysis device (patented by Meijing), with a processing capacity of 10L / h; one oxygen tank , with an effective volume of 10L; 1 aerobic tank with an effective volume of 10L; Meijing high-efficiency compound microbial strains 8L (Meijing patent).

[0068] 2.3 Process flow and description

[0069] Suggestions on the process flow of pesticide wastewater treatment Figure 4 .

[0070] This experiment is mainly aimed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com