Polylol for foamed plastic and polyisocyanurate foamed plastic adopting same

A technology of polyisocyanurate and foam plastics, applied in the field of polyisocyanurate foam plastics and polyols for foam plastics, can solve the problems of increasing foam brittleness, reducing foam fluidity, and decreasing flame retardancy, etc. To achieve the effect of improving the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

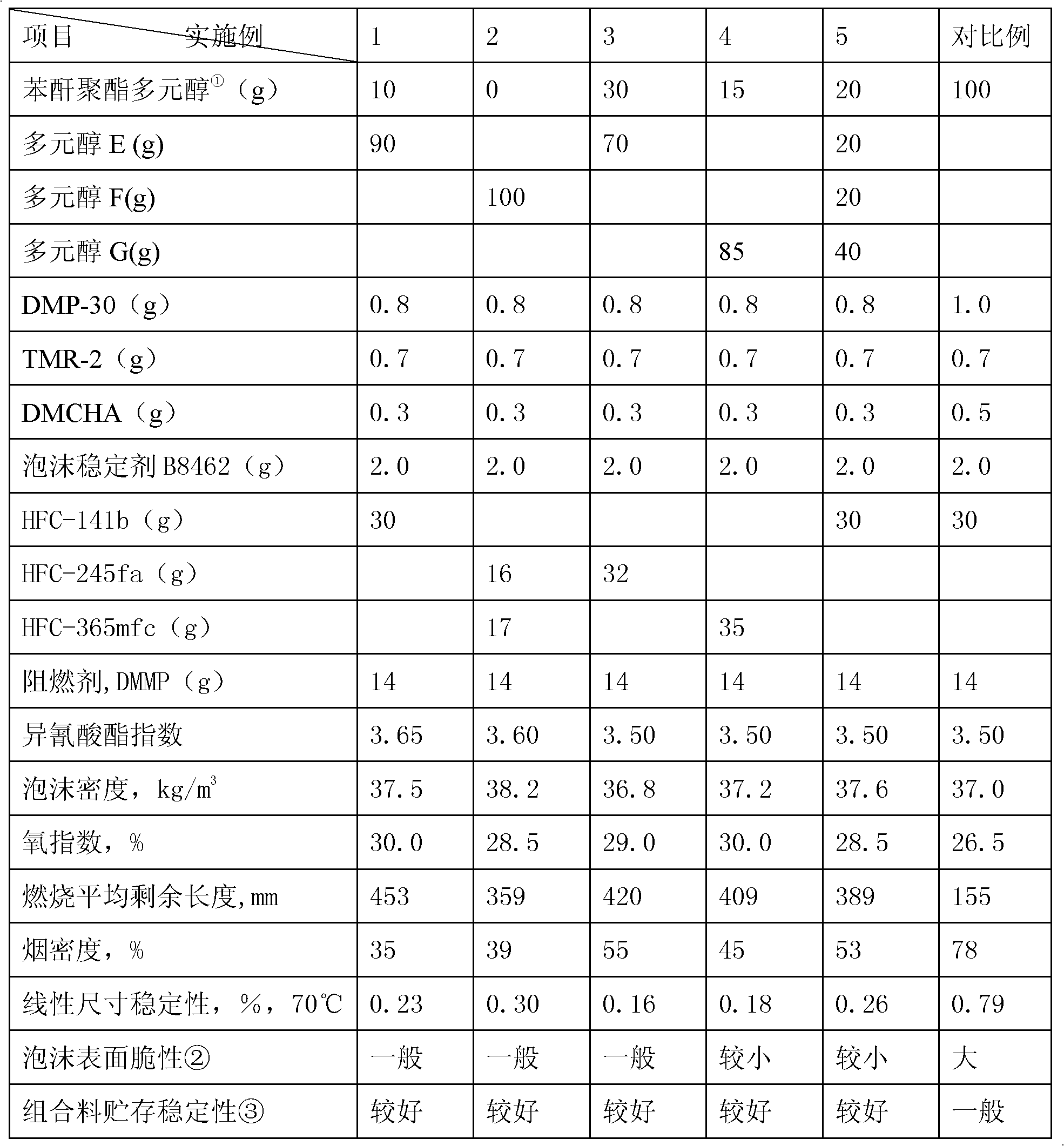

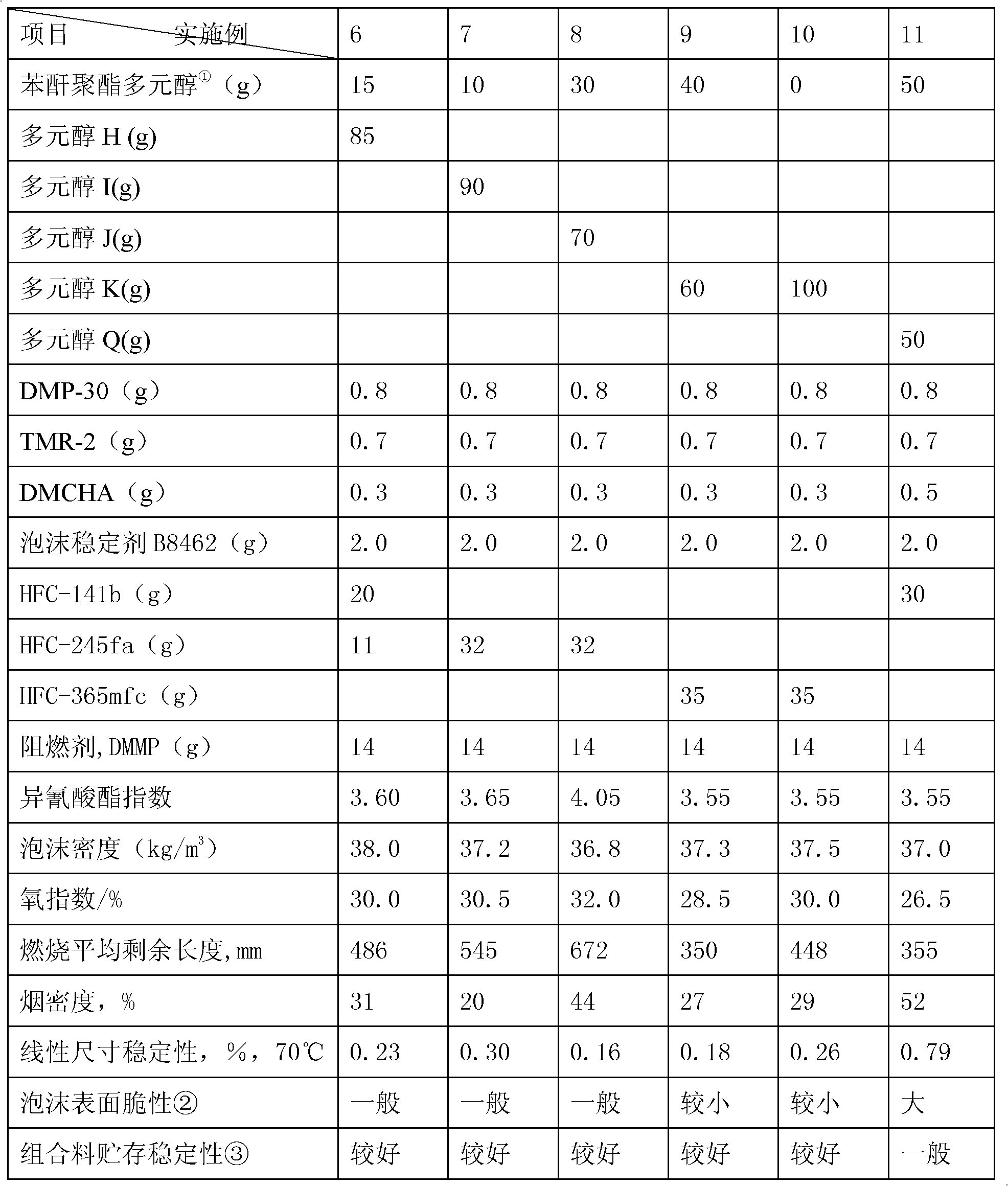

Examples

Embodiment 1

[0038] Add 180g of paraformaldehyde, 126g of melamine and 120g of water into a reactor with a stirrer and temperature control, adjust the reaction system to a pH value of 8 to 8.5 with 20% potassium hydroxide, raise the temperature to 70°C, and keep warm After 3 hours, the white solid of methylolated melamine with a methylolation degree of 5.85 was refined; 224 g of methanol was added to the white solid of methylolated melamine, the reaction temperature was controlled at 40°C, and the reaction system was adjusted to pH=3.5 with formic acid , heated up to 65°C, and kept warm for 6 hours. After testing, a clear liquid of methylolated melamine with 75% of the methylol groups blocked by methanol was obtained; then 184g of diethanolamine was added, and the reaction system was adjusted to pH=8.3 with formic acid to control the reaction. Keep the temperature at 70°C for 6 hours; raise the temperature to 100°C, vacuumize under the condition of -0.02~-0.1MPa to remove small molecules fo...

Embodiment 2

[0040] Add 180g of paraformaldehyde, 126g of melamine and 110g of water into a reactor with a stirrer and temperature control, adjust the reaction system to a pH value of 8 to 8.5 with 20% potassium hydroxide, raise the temperature to 70°C, and keep warm After 2.8 hours, a white solid of methylolated melamine with a degree of methylolation of 5.75 was refined; 205 g of methanol was added to the white solid of methylolated melamine, the reaction temperature was controlled at 40°C, and the reaction system was adjusted to pH=3.5 with hydrochloric acid , heat up to 68°C and keep warm for 6 hours. After testing, a clear liquid of methylolated melamine with 80% of the methylol groups blocked by methanol is obtained; then add 169g of diethanolamine, and adjust the reaction system to pH=8.4 with hydrochloric acid to control the reaction. Keep the temperature at 70°C for 6 hours; raise the temperature to 105°C, vacuumize under the condition of -0.02~-0.1MPa to remove small molecules for...

Embodiment 3

[0042] Add 187.5g of paraformaldehyde, 100g of water, and 126g of melamine into a reactor with a stirrer and temperature control, adjust the reaction system to a pH value of 8.5-9.0 with 20% potassium hydroxide, and raise the temperature to 75°C , kept warm for 2 hours, and the refined methylolation degree was 5.8 methylolated melamine white solid; in the methylolated melamine white solid, 250 g of methanol was added, and the reaction temperature was controlled at 40° C.; the reaction system was regulated with 67% nitric acid To pH = 4.0, raise the temperature to 62°C and keep it warm for 7 hours. After testing, a clear liquid of methylolated melamine with 78% of the methylol groups blocked by methanol is obtained; then add 214g of diisopropanolamine and adjust the reaction system with phosphoric acid pH = 8.1, control the reaction temperature at 70°C, keep it warm for 6h; raise the temperature to 105°C, vacuumize and remove small molecules under the condition of -0.02~-0.1MPa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com