Preparation method of silk fibroin/hydroxyapatite/collagen composite porous stent

A technology of hydroxyapatite and silk fibroin, applied in the field of materials, can solve the problems of time-consuming and complicated operation, and achieve the effects of good pore connectivity, high porosity, moderate water absorption and expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

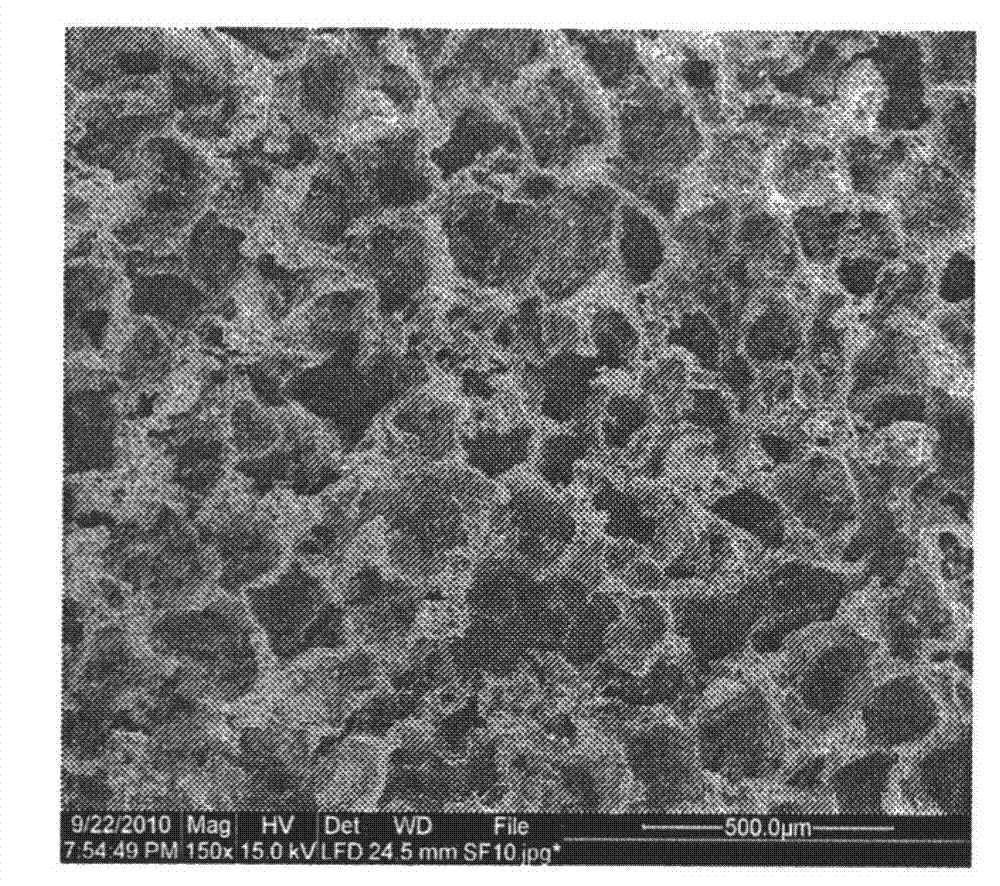

Embodiment 1

[0043] 1. Preparation of silk fibroin aqueous solution

[0044] Take 20 g of silkworm cocoons from which pupae have been removed, add 0.02mol / L Na 2 CO 3 2000g of aqueous solution, boiled for 30 minutes, took out and wrung out, rinsed with distilled water; repeated the above operation twice, and dried in vacuum at 50°C for 12 hours to obtain degummed silk; 5g of degummed silk was placed in 50g of 9.3mol / L LiBr aqueous solution, Incubate at 50°C until the degummed silk is completely dissolved, put it into a dialysis bag with a cut-off molecular weight of 3500 Daltons, dialyze in distilled water with a flow rate of 1 mL / min for 5 days, and centrifuge to obtain the supernatant as silk fibroin aqueous solution. The mass fraction of silk fibroin in silk fibroin aqueous solution was determined by Coomassie brilliant blue method, diluted with distilled water until the mass fraction of silk fibroin was 6%, and stored at 5°C for later use.

[0045] 2. Prepare the scaffold

[0046]Mi...

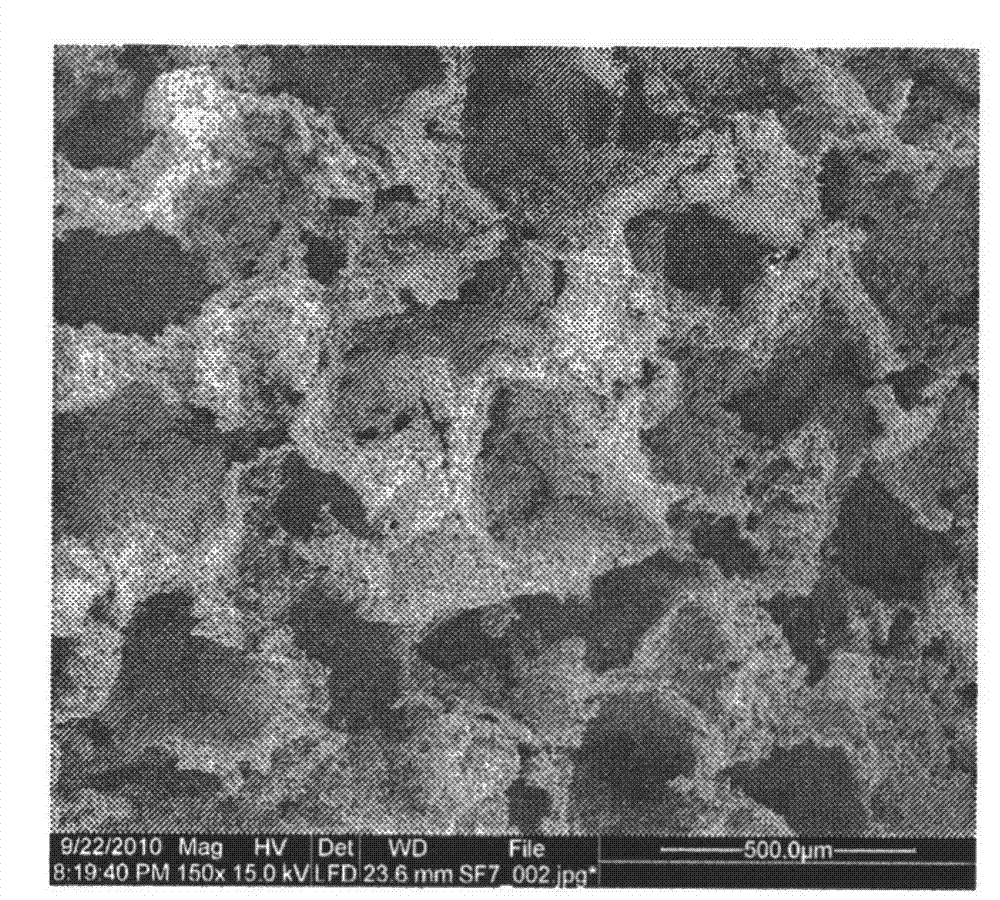

Embodiment 2

[0048] In step 2 of preparing the scaffold in Example 1, 4 g of NaCl with a particle size of 180-250 μm and 0.08 g of hydroxyapatite are mixed evenly, and the mass ratio of NaCl to hydroxyapatite is 1:0.02. Other steps of this step Same as Example 1. The other steps were the same as in Example 1 to prepare a silk fibroin / hydroxyapatite / collagen composite porous scaffold.

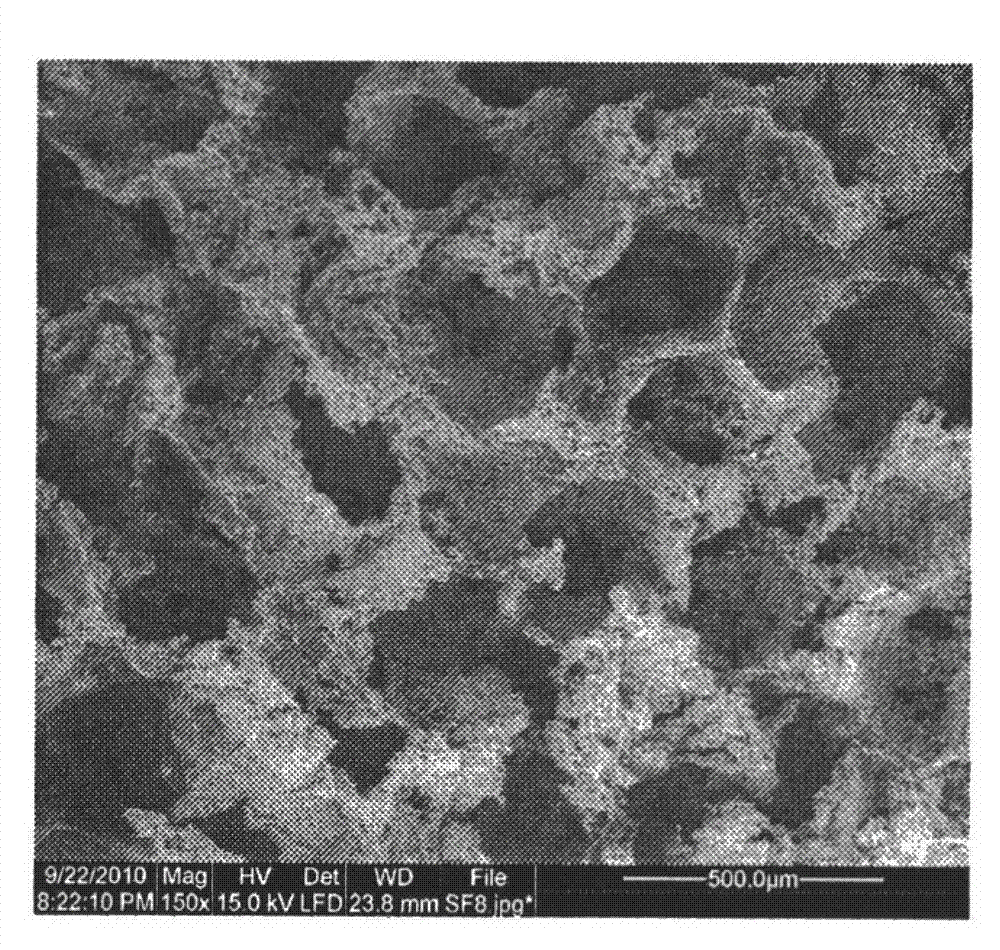

Embodiment 3

[0050] In step 2 of preparing the scaffold in Example 1, 4 g of NaCl with a particle size of 180-250 μm and 0.24 g of hydroxyapatite were mixed evenly, and the mass ratio of NaCl to hydroxyapatite was 1:0.06. Other steps of this step Same as Example 1. The other steps were the same as in Example 1 to prepare a silk fibroin / hydroxyapatite / collagen composite porous scaffold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com