Manufacturing method of flourescent material taking mg-alpha-sialo<n> as host lattice

A manufacturing method and technology of fluorescent materials, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of reducing the luminous quality of fluorescent materials, high cost, and polarized light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Magnesium metal, silicon powder, aluminum metal, aluminum oxide, sodium pernitride, ammonium chloride, and europium oxide are mixed in a molar ratio of 0.8:9.2:2:0.4:9.936:4.829:0.03 and placed in a compression molding machine The ingot is punched into an ingot with a diameter of 1.7 cm and a height of 1.0 cm.

[0057] Next, prepare an igniter, which is made of magnesium metal and ferroferric oxide mixed in a molar ratio of 4:1; then coat the igniter on the ingot, and mold it with a compression molding machine. The ingot was formed into a reaction ingot with a diameter of 3.0 cm and a height of 2.4 cm.

[0058] Then, the reaction ingot is placed in a thermal insulation device and aluminum nitride is filled between the reaction ingot and the thermal insulation device to form a reaction unit.

[0059] Finally, place the reaction unit in a closed reactor filled with 5 atmospheres of nitrogen, and then use a tungsten wire coil to energize the reaction ingot to burn the ign...

Embodiment 2-31

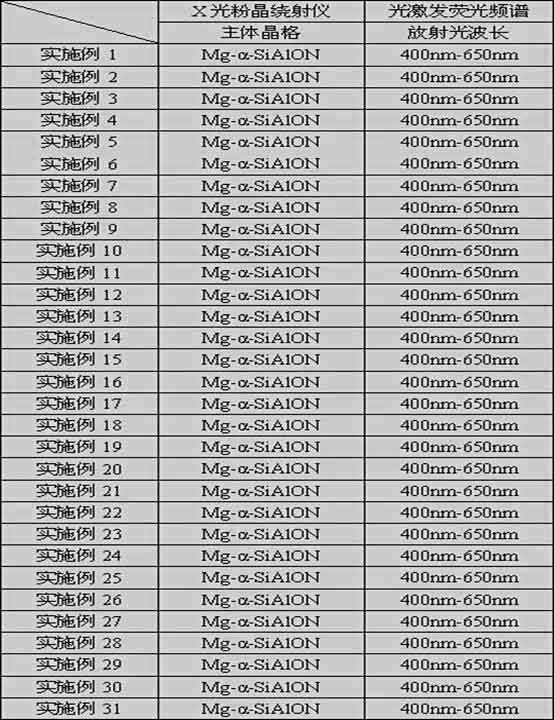

[0061] These embodiments are substantially similar to the manufacturing method of the above-mentioned embodiment 1, and the difference lies in: the composition types and composition amounts of the reaction ingots in these embodiments are different from the above-mentioned embodiments. Please refer to Table 1, which illustrates the composition types and composition amounts of the reaction ingots of Examples 2-31 of the present invention.

[0062] Table 1

[0063]

[0064] analyze

Embodiment 1-31

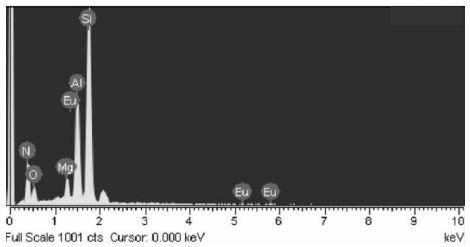

[0066] In order to further understand the physical and chemical properties of the fluorescent material of the above-mentioned examples 1-31 in which Mg-α-SiAlON is the host lattice. First, use an Energy Dispersive Spectrometer (Energy Dispersive Spectrometer; EDS) to analyze the chemical composition of the fluorescent material in which Mg-α-SiAlON is the main lattice in these embodiments, X-ray powder crystal diffraction (X-ray Diffraction; XRD ) to identify the Mg-α-SiAlON of these embodiments as the host lattice of the fluorescent material of the host lattice. Then, photoluminescence (PL) is used to detect the emitted light wavelength of the fluorescent material of the embodiments in which Mg-α-SiAlON is the host lattice.

[0067] Please see figure 1 Shown is the result of the energy distribution spectrometer of the fluorescent material in which Mg-α-SiAlON is the host lattice in Example 1.

[0068] Please refer to Table 2 again, which is the results of X-ray powder crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com