Botryococcus braunii magnetic separation method

A technology of botrytis brauneni and magnetic separation, applied in the direction of unicellular algae, ferrous oxides, nanotechnology, etc., can solve the problem of low yield and quality of botrytis braunenii cells, inability to regenerate and recycle the particles, and unproductive problems. Considering the coupling of oil extraction and separation medium recovery, the effects of easy scale-up, reduced production cost, and simple synthesis steps are achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Using the high-efficiency recovery method of magnetic nanoparticles for the magnetic separation of Staphylococcus branici of the present invention, Fe in the magnetic separation of Staphylococcal 3 o 4 The recovery of nanoparticles, the steps are as follows:

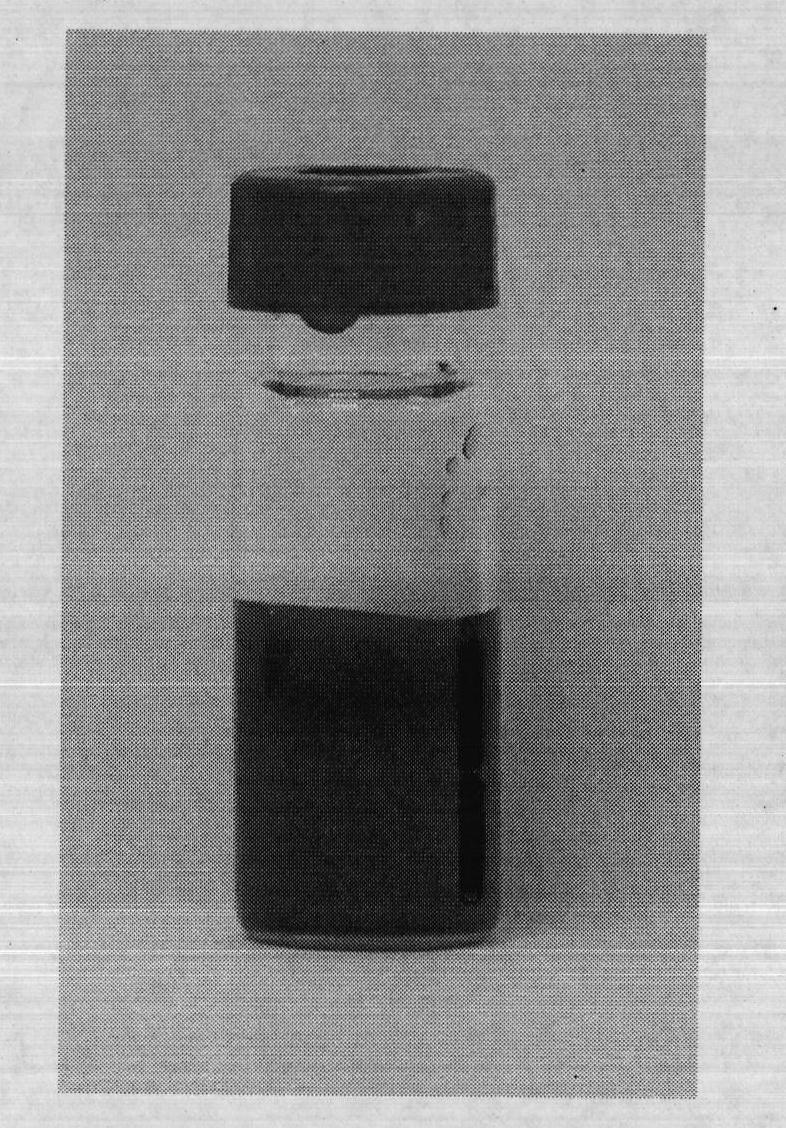

[0056] (1) Fe obtained by preparing 3 o 4 The nanoparticles are dispersed in deionized water to form a stable suspension, prepared into a magnetic separation medium with a concentration of 1% (w / v), and then put into a refrigerator for further storage.

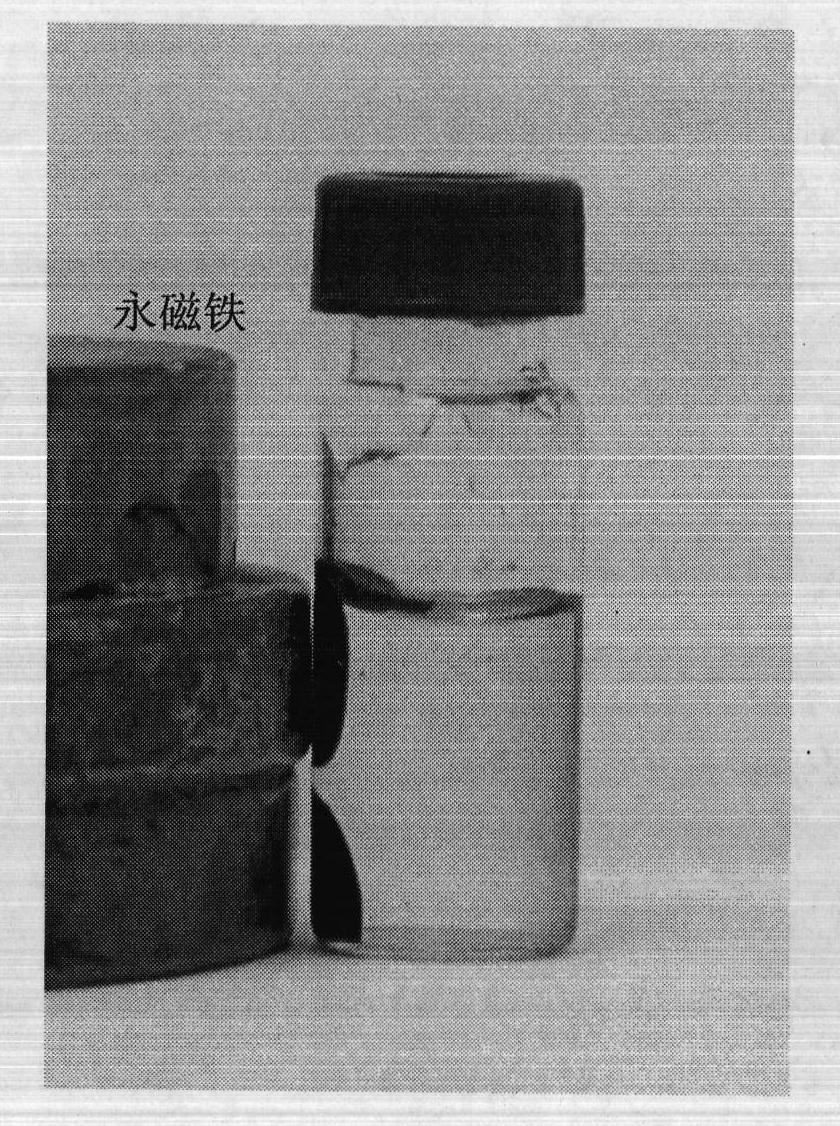

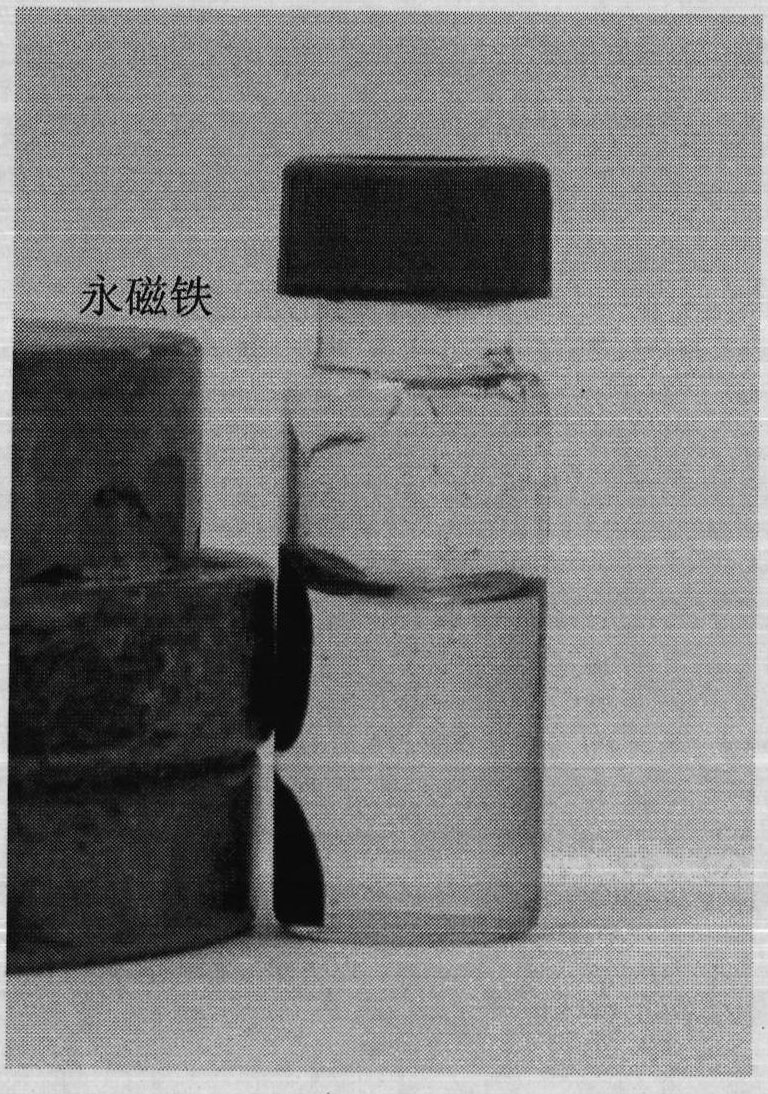

[0057] (2) put the botrytis brannica culture solution obtained by cultivating into a stirred reactor, add a magnetic separation medium at a rotating speed of 200rpm, the consumption of the magnetic separation medium is 0.02% (w / v), and the stirring time is 1.5 minutes; After the separation, the supernatant was removed, and the separated botrytis brachyphytum cells and the polymer of the magnetic medium were collected, and the recovery rate of the botrytis brach...

Embodiment 2

[0063] Using the high-efficiency recovery method of magnetic nanoparticles for the magnetic separation of Staphylococcus branici of the present invention, Fe in the magnetic separation of Staphylococcal 3 o 4 The recovery of nanoparticles, the steps are as follows:

[0064] (1) Fe obtained by preparing 3 o 4 The nanoparticles are dispersed in deionized water to form a stable suspension, prepared into a magnetic separation medium with a concentration of 0.5% (w / v), and then put into a refrigerator for storage.

[0065](2) Put the botrytis culture solution obtained by cultivation into a stirring reactor, add a magnetic separation medium at a rotating speed of 100rpm, the consumption of the magnetic separation medium is 0.01% (w / v), and the stirring time is 2 minutes; Finally, the supernatant was removed, and the isolated botrytis brachyphytum cells and the polymer of the magnetic medium were collected, and the botrytis recovery rate reached 99.5%;

[0066] (3) At room temper...

Embodiment 3

[0071] Using the high-efficiency recovery method of magnetic nanoparticles for the magnetic separation of Staphylococcus branici of the present invention, Fe in the magnetic separation of Staphylococcal 3 o 4 The recovery of nanoparticles, the steps are as follows:

[0072] (1) Fe obtained by preparing 3 o 4 Nanoparticles are dispersed in deionized water to form a stable suspension, prepared into a magnetic separation medium with a concentration of 2% (w / v), and then put into a refrigerator for further storage.

[0073] (2) Put the botrytis culture solution obtained by cultivation into a stirred reactor, add a magnetic separation medium at a rotating speed of 300rpm, the consumption of the magnetic separation medium is 0.03% (w / v), and the stirring time is 1 minute; Finally, the supernatant was removed, and the isolated botrytis brachyphytum cells and the polymer of the magnetic medium were collected, and the botrytis recovery rate reached 99.3%;

[0074] (3) At room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com