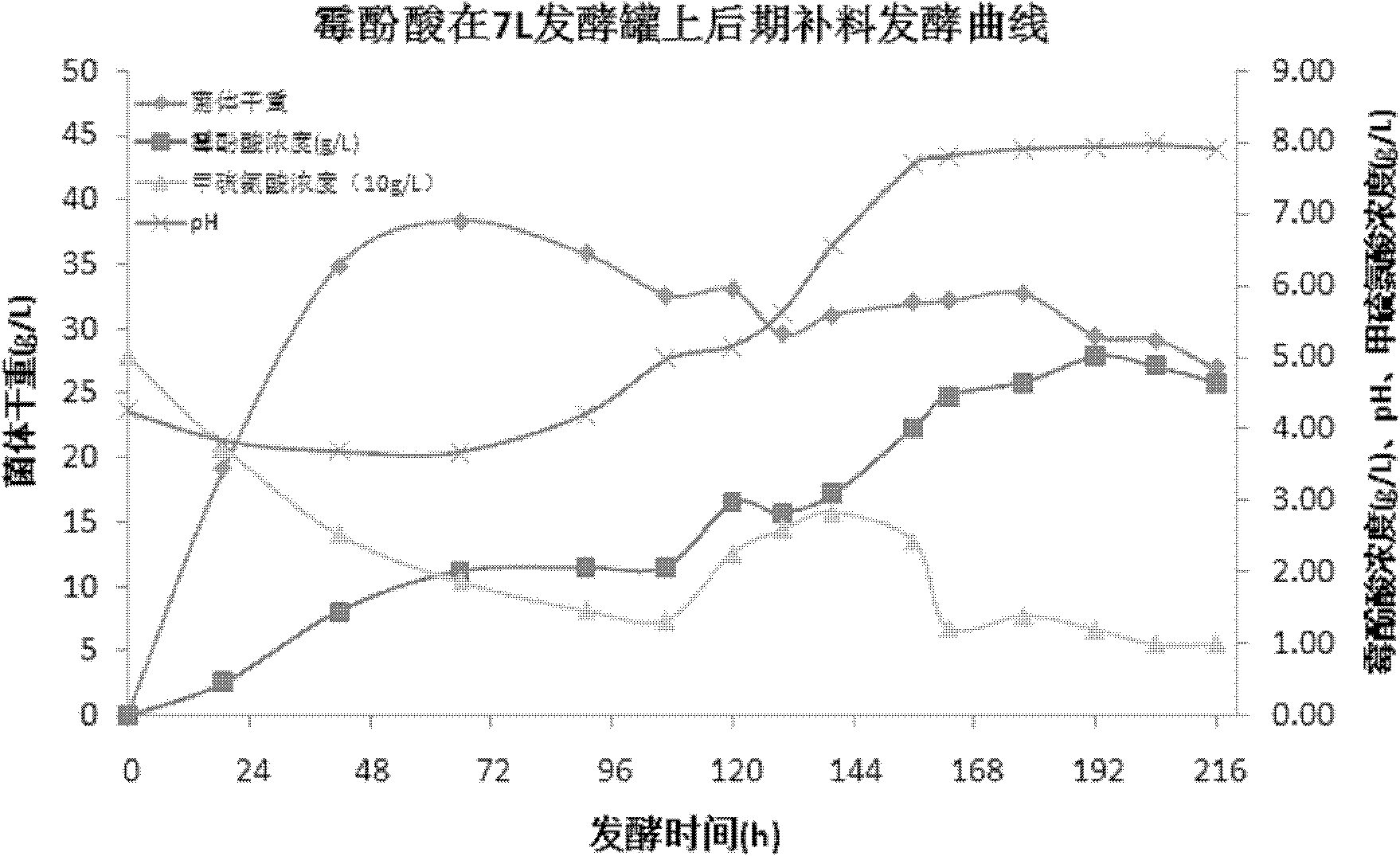

Method for producing mycophenolic acid by efficiently accumulating Penicillium brevicompactum and supplementing precursor in later period

A technology for precursors and mycophenolic acid, which is applied in the field of high-efficiency cumulative production of mycophenolic acid by supplementing precursors at a later stage and utilizing Penicillium breviscapae, can solve the problems of long cycle and no significant increase in yield, and achieves high production efficiency. , the effect of batch fermentation time is close, fermentation cycle is close

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The slant was cultured in PDA medium for 10 days and placed in a 4°C refrigerator to store the slant. Get the slanted seeds and use 30% glycerol to elute the spores to form a spore suspension, and 2% are inoculated into the seed shake flask medium (g / L): peptone 2.0, yeast extract 1.0, starch 1.0, glucose (C 6 h 12 o 6 ·H 2 O) 10.0, pH 6.5. Cultivate for 72 hours under the conditions of 28° C. and a rotating speed of 220 r / min, and inoculate 10% of the inoculum size into a 7L fermenter according to the volume of the medium. In the initial stage of fermentation, an optimized fermentation medium (g / L): glucose (C 6 h 12 o 6 ·H 2 O) 93.4, glycine (C 2 h 5 NO 2 ) 13.4, Potassium dihydrogen phosphate (KH 2 PO 4 )3.0, magnesium sulfate (MgSO 4 ·7H 2 O) 1.0, Methionine (C 5 h 11 o 2 NS) 0.5, distilled water as the solvent, pH 4.6, the carbon and nitrogen sources were sterilized separately, and an appropriate amount of foam enemy was added.

[0022] Control the...

Embodiment 2

[0024] The slant was cultured in PDA medium for 10 days and placed in a 4°C refrigerator to store the slant. Get the slanted seeds and use 30% glycerol to elute the spores to form a spore suspension, and 2% is inoculated into the seed shake flask medium (g / L): peptone 2.0, yeast extract 1.0, starch 1.0, glucose (C 6 h 12 o 6 ·H 2 O) 10.0, pH 6.5. Cultivate for 72 hours under the conditions of 28° C. and a rotating speed of 220 r / min, and inoculate 10% of the inoculum size into a 7L fermenter according to the volume of the medium. In the initial stage of fermentation, an optimized fermentation medium (g / L): glucose (C 6 h 12 o 6 ·H 2 O) 150, glycine (C 2 h 5 NO 2 ) 14, potassium dihydrogen phosphate (KH 2 PO 4 )2.0, magnesium sulfate (MgSO 4 ·7H 2 O) 0.5, methionine (C 5 h 11 o 2 NS) 1.0, distilled water as the solvent, pH 4.4, the carbon and nitrogen sources were sterilized separately, and an appropriate amount of foam enemy was added.

[0025] Control the fer...

Embodiment 3

[0027] The slant was cultured in PDA medium for 10 days and placed in a 4°C refrigerator to store the slant. Get the slanted seeds and use 30% glycerol to elute the spores to form a spore suspension, and 2% is inoculated into the seed shake flask medium (g / L): peptone 2.0, yeast extract 1.0, starch 1.0, glucose (C 6h 12 o 6 ·H 2 O) 10.0, pH 6.5. Cultivate for 72 hours under the conditions of 28° C. and a rotating speed of 220 r / min, and inoculate 10% of the inoculum size into a 7L fermenter according to the volume of the medium. In the initial stage of fermentation, an optimized fermentation medium (g / L): glucose (C 6 h 12 o 6 ·H 2 O) 100.0, glycine (C 2 h 5 NO 2 ) 15, potassium dihydrogen phosphate (KH 2 PO 4 )4.0, magnesium sulfate (MgSO 4 ·7H 2 O) 0.5, methionine (C 5 h 11 o 2 NS) 0.5, distilled water as the solvent, pH 4.8, the carbon and nitrogen sources were sterilized separately, and an appropriate amount of foam enemy was added.

[0028] The fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com