Preparation method of nano Fe3O4/CeO2 composite material and application thereof

A composite material, fe3o4 technology, used in chemical instruments and methods, chemical/physical processes, oxidized water/sewage treatment, etc., can solve problems such as large amount of reagents, increase COD, secondary pollution, etc., and achieve complete secondary pollution. , No secondary pollution, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of Nano-CeO by Liquid Phase Precipitation 2 Particles, the steps are as follows: the concentration of 0.1mol / L (NH 4 ) 2 CO 3 ·H 2 O was quickly added as a precipitant to Ce(NO 3 ) 3 ·6H 2 O solution, (NH 4 ) 2 CO 3 ·H 2 O solution and Ce(NO 3 ) 3 ·6H 2 The volume ratio of the O solution is 3:2, and the surfactant polyethylene glycol 4000 (PEG 4000) of 4g / L is added at the same time, the reaction time is 10min, the reaction temperature is 40°C, stirring, and the reaction generates a precursor; the precursor sol After filtering, wash twice with deionized water to remove impurities, put the filtered precursor into a beaker filled with absolute ethanol, and disperse it with ultrasonic waves for 10 minutes; then filter, vacuum dry, and then bake in air at 300 °C 1h, get nano-CeO 2 particles.

[0030] Then nano-CeO 2 The particles are used as the carrier, and the Massart hydrolysis method in the co-precipitation method is used to prepare nano-Fe ...

Embodiment 2

[0037] Preparation of Nano-CeO by Liquid Phase Precipitation 2 Particles, the steps are as follows: the concentration of 0.1mol / L (NH 4 ) 2 CO 3 ·H 2 O was quickly added as a precipitant to Ce(NO at a concentration of 0.2mol / L 3 ) 3 ·6H 2 O solution, (NH 4 ) 2 CO 3 ·H 2 O solution and Ce(NO 3 ) 3 ·6H 2The volume ratio of the O solution is 3:1, and 4g / L surfactant polyethylene glycol 4000 (PEG 4000) is added at the same time, the reaction time is 20min, the reaction temperature is 60°C, stirring, and the reaction generates a precursor; the precursor sol After filtering, wash twice with deionized water to remove impurities, put the filtered precursor into a beaker filled with absolute ethanol, and disperse it with ultrasonic waves for 10 minutes; then filter, vacuum dry, and then bake in air at 300 °C 1h, get nano-CeO 2 particles.

[0038] Then nano-CeO 2 The particles are used as the carrier, and the Massart hydrolysis method in the co-precipitation method is us...

Embodiment 3

[0045] Nano Fe 3 o 4 / CeO 2 The preparation process of the composite material is the same as in Example 1.

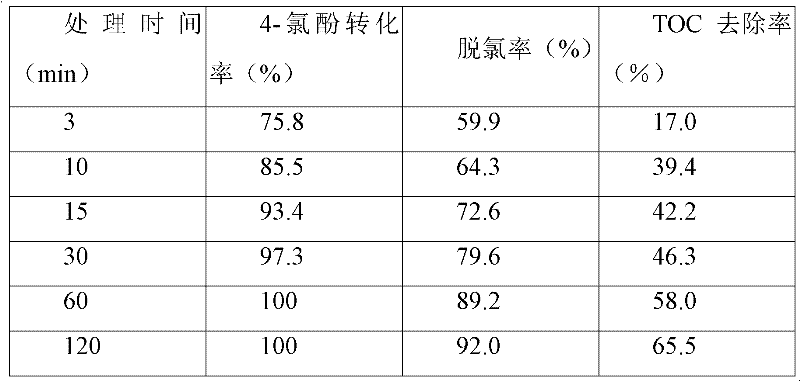

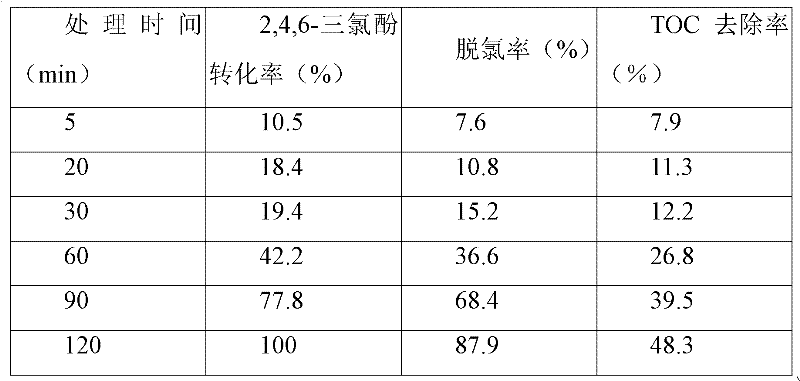

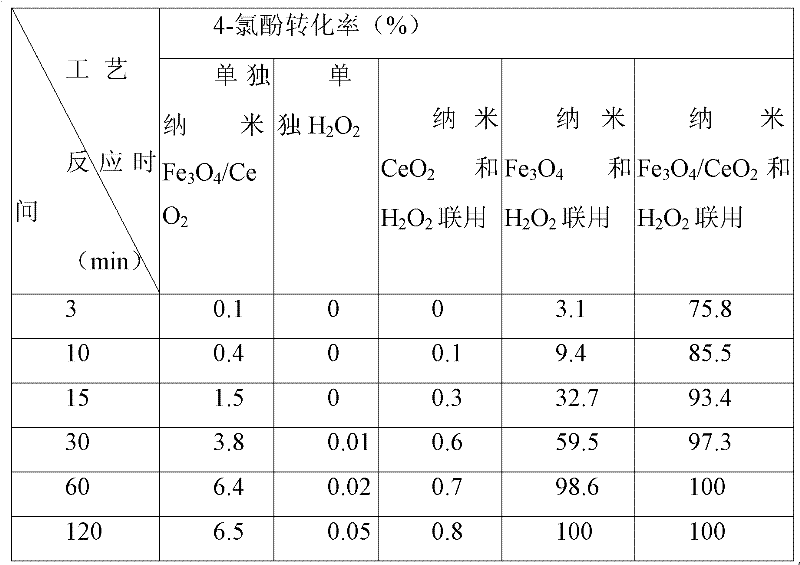

[0046] Experiments compared the addition of nano-Fe alone 3 o 4 / CeO 2 , add H alone 2 o 2 , Nano CeO 2 and H 2 o 2 Combined use, nano-Fe 3 o 4 and H 2 o 2 Combined use, nano-Fe 3 o 4 / CeO 2 and H 2 o 2 The difference in the removal rate of 4-chlorophenol under the combination of five processes.

[0047] Add nano-Fe separately 3 o 4 / CeO 2 In the experiment, the Erlenmeyer flask was used as the reactor, and the treatment conditions were 4-chlorophenol-containing wastewater with a concentration of 100mg / L, pH 3.0, and the addition of 2.0g / L nano-Fe 3 o 4 / CeO 2 , the reactor was placed in a water bath shaker with a rotation speed of 150 rpm and a temperature of 30 °C.

[0048] Add H alone 2 o 2 In the experiment, 30mM H was added to the reactor 2 o 2 , and the other conditions are the same as above.

[0049] nano-CeO 2 and H 2 o 2 In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com