Functional chestnut kernels with activities of lowering blood pressure and resisting oxidation and preparation method thereof

A chestnut kernel and functional technology, which is applied in the field of functional chestnut kernels with blood pressure lowering and antioxidant activity and its preparation, can solve the problems of ignoring food attributes and achieve the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, preparation functional chestnut

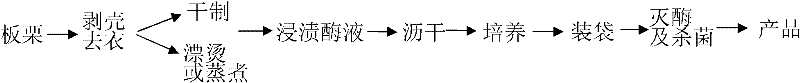

[0037] 1 Process route and operating points of functional chestnut kernel preparation

[0038] according to figure 1 The process flow shown was carried out.

[0039] Key points of operation: Heat fresh chestnuts in boiling water for 2 minutes, then manually peel off the shells while they are still hot, then immerse them in the color-protecting solution for 30 minutes. 2% NaCl+2% absolute ethanol (reference: Chestnut vacuum freeze-drying process research [D]. Baoding: Hebei Agricultural University, 2005.), in order to achieve the purpose of preventing browning and destroying the dense layer on the chestnut surface, after that Freeze drying was carried out. Soak the dried chestnut kernels in the enzyme solution for 2 hours, rehydrate the dried chestnut kernels, take them out and drain them, and then cultivate them at a suitable temperature. Put it into a high-temperature-resistant aluminum foil bag, seal it, and treat it...

Embodiment 2

[0064] Embodiment 2, preparation functional chestnut

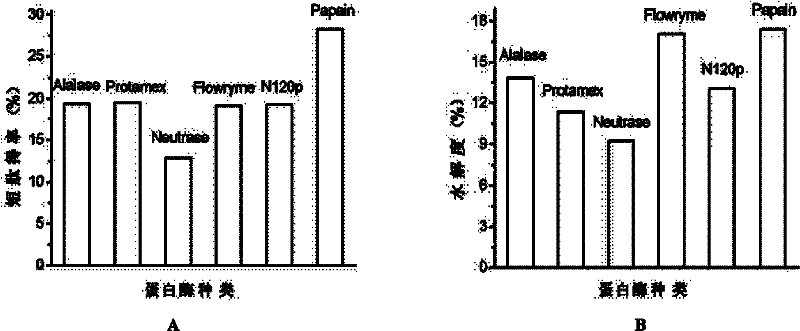

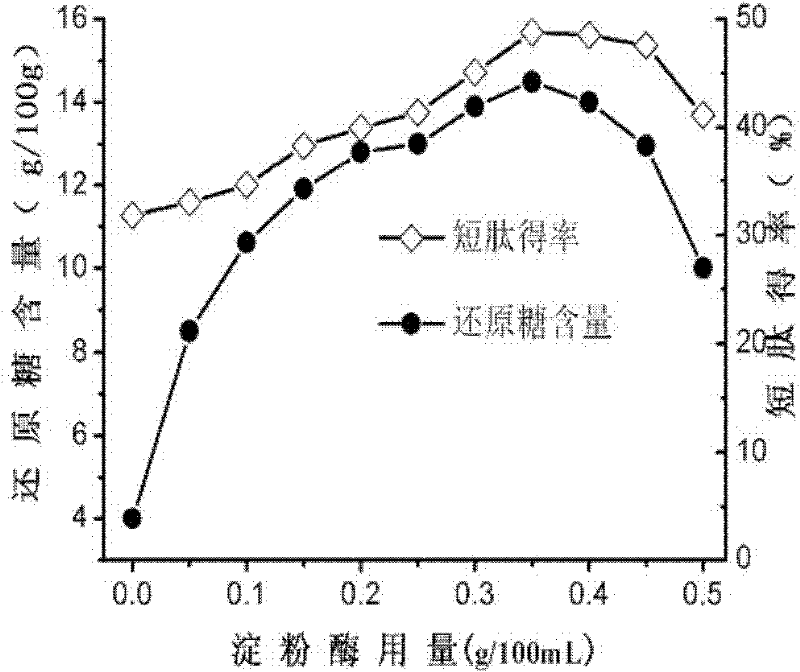

[0065] Heat fresh chestnuts in boiling water for 2 minutes, peel off the shells by hand while they are still hot, then immerse them in the color protection solution for 30 minutes. The composition of the color protection solution is 0.01% tea polyphenols + 0.2% citric acid + 0.1% EDTA + 2% NaCl +2% absolute ethanol to achieve the purpose of preventing browning and destroying the dense layer on the surface of chestnut kernels. Afterwards, blanching in 95°C water for 5 minutes, immersing the treated chestnuts in enzyme solution (enzyme solution composition: papain, Flowryme, α-amylase, wherein, the mass ratio of papain and Flowryme is 2:1, α- Soak the amylase in 0.35g / 100ml enzyme liquid) for 2 hours to make the enzyme liquid penetrate into the chestnut kernel (the enzyme dosage to control the hydrolysis of chestnut kernel protein is 8000U / g 栗仁蛋白 ), take out and drain, and then incubate at 55°C for 15 hours.

[0066] The s...

Embodiment 3

[0067] Embodiment 3, the mensuration of the functional activity of functional chestnut

[0068] 1 Determination of ACE inhibitory activity

[0069] 1.1 Chromatographic conditions

[0070] Column: SunFire TM C 18 Analytical chromatographic column (4.6mm×250mm, 5μm); detection wavelength: 228nm; flow rate: 0.4mL / min; mobile phase A is pure water (containing 0.05% trifluoroacetic acid), mobile phase B is chromatographic acetonitrile (containing 0.05% trifluoroacetic acid); injection volume: 20 μL, automatic injection; column temperature 30 °C.

[0071] 1.2 Preparation of reagents and test solution

[0072] ACE solution: Dissolve 1U ACE (angiotensin-converting enzyme inhibitor) in 2mL 0.1mol / L boric acid buffer (pH8.3, containing 0.4mol / L NaCl); HHL solution: Take an appropriate amount of HHL, add 0.1mol / L boric acid buffer solution (pH 8.3, containing 0.4mol / L NaCl) was dissolved and made into 5mmol / L HHL solution; preparation of hippuric acid standard solution: take an app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com