Preparation method of 2,4-dicumyl phenol

A technology of cumylphenol and phenol, which is applied in the preparation of organic compounds, chemical instruments and methods, and the production of bulk chemicals, can solve the problems of difficult operation of organic phenols, poor selectivity, waste water, etc., to increase the reaction rate and promote Dissolving speed, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

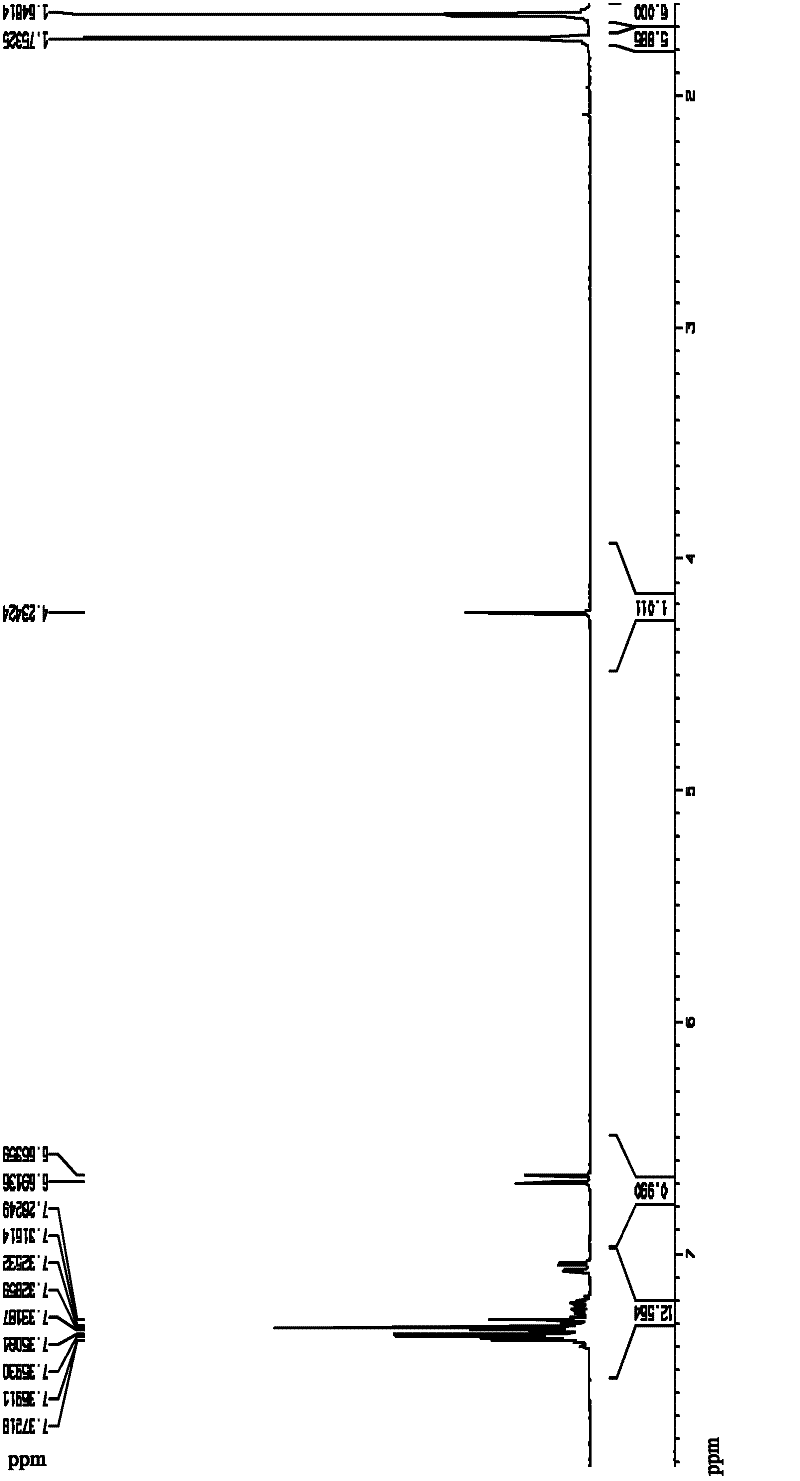

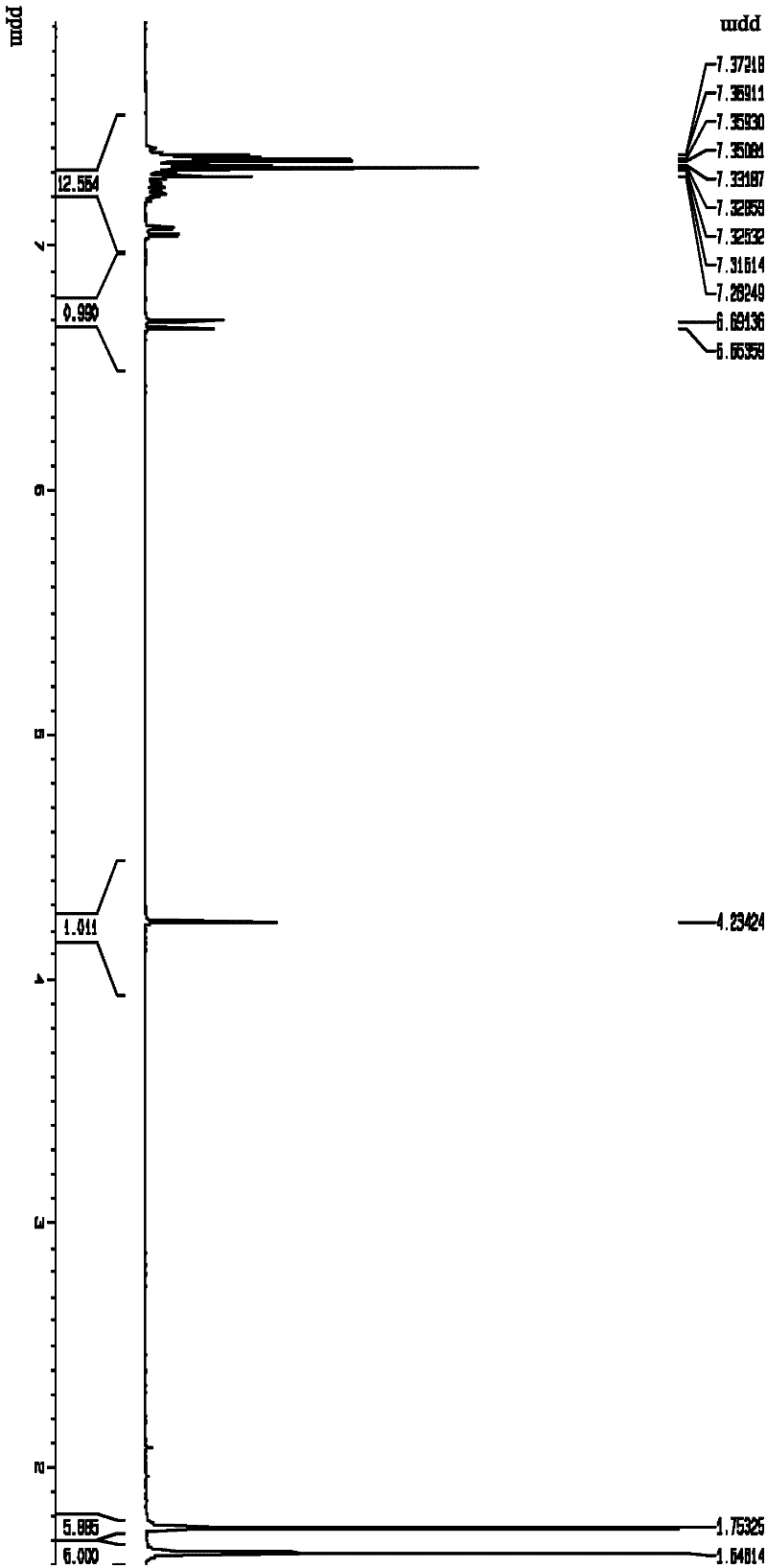

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: this embodiment is the preparation method of 2,4-dicumylphenol, which is realized through the following steps:

[0026] 1. Under nitrogen protection, add phenol and homogeneous composite catalyst into the reactor, then heat up to 50-60°C, then remove the heating source to stop heating, then add α-methylstyrene dropwise into the reactor, Control the rate of addition of α-methylstyrene so that the reaction temperature is between 90 and 100°C. After the dropwise addition of α-methylstyrene is completed, the reaction is then continued for 20 to 40 minutes at a temperature of 90 to 100°C, wherein , the homogeneous composite catalyst is a mixture of quaternary ammonium salt and p-toluenesulfonic acid, the mass ratio of quaternary ammonium salt and p-toluenesulfonic acid in the homogeneous composite catalyst is 0.2~0.4:1, and the quality of the homogeneous composite catalyst is phenol 1% to 4% of the mass, the molar ratio of α-methylstyrene to phenol i...

specific Embodiment approach 2

[0033] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the quaternary ammonium salt in step one is tetraethyl ammonium bromide, tetrabutyl ammonium bromide, tetraheptyl ammonium bromide, tetraoctyl ammonium bromide , tetrahexadecyl ammonium bromide, benzyl trimethyl ammonium bromide, tetraethyl ammonium chloride, tetrabutyl ammonium chloride, tetraheptyl ammonium chloride, tetraoctyl ammonium chloride, forty six Alkyl ammonium chloride or benzyl trimethyl ammonium chloride. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the dropping rate of α-methylstyrene is controlled so that the reaction temperature is between 90°C and 95°C. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0035] In this embodiment, the temperature of the system can be maintained at 90-95° C. by controlling the rate of addition and using the heat released by the reaction itself.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com