Characteristic fertilizer for cigarette and production method thereof

A production method and characteristic technology, applied in application, organic fertilizer, fertilization device, etc., can solve the problems of slow growth of tobacco leaves, excessive greenness and late maturity of tobacco plants, barren tobacco leaves, etc., achieve short production cycle, simple production process, and improve environmental cleanliness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

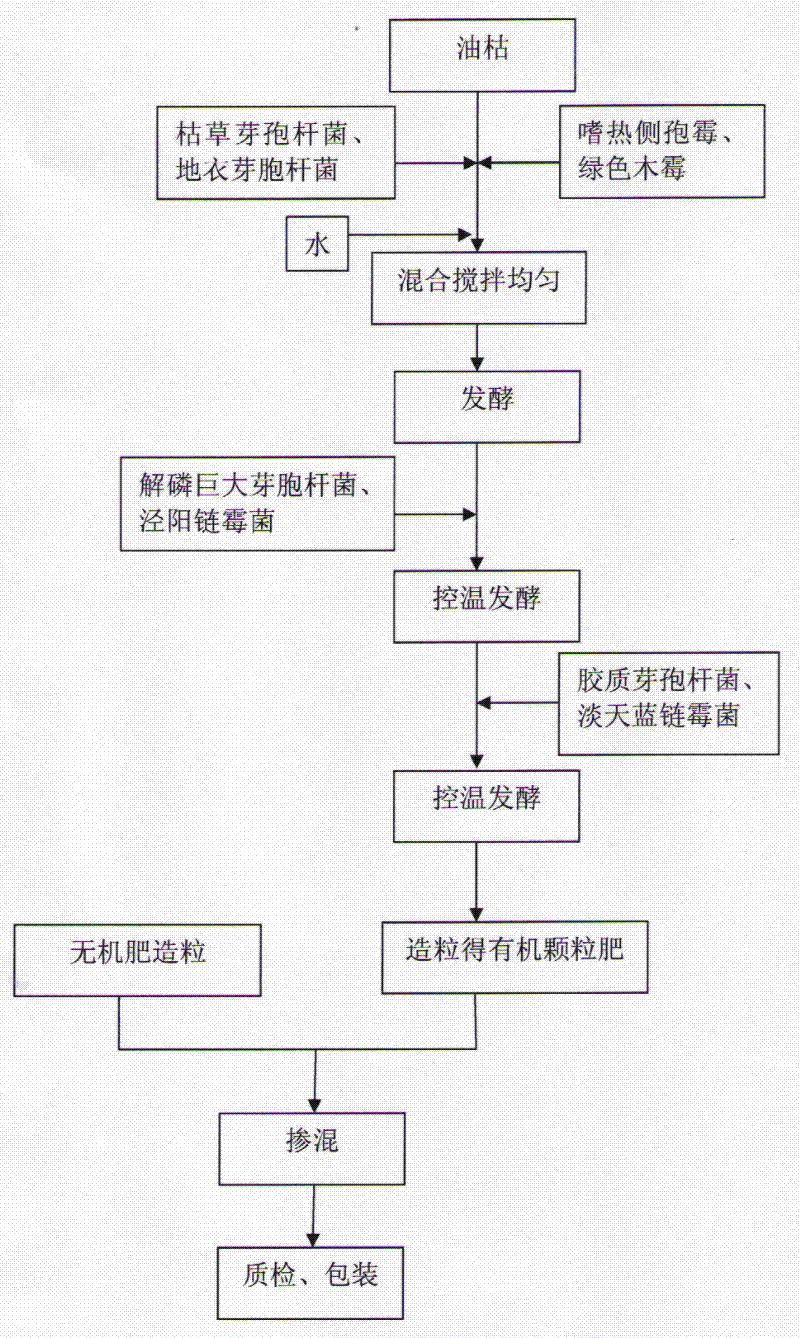

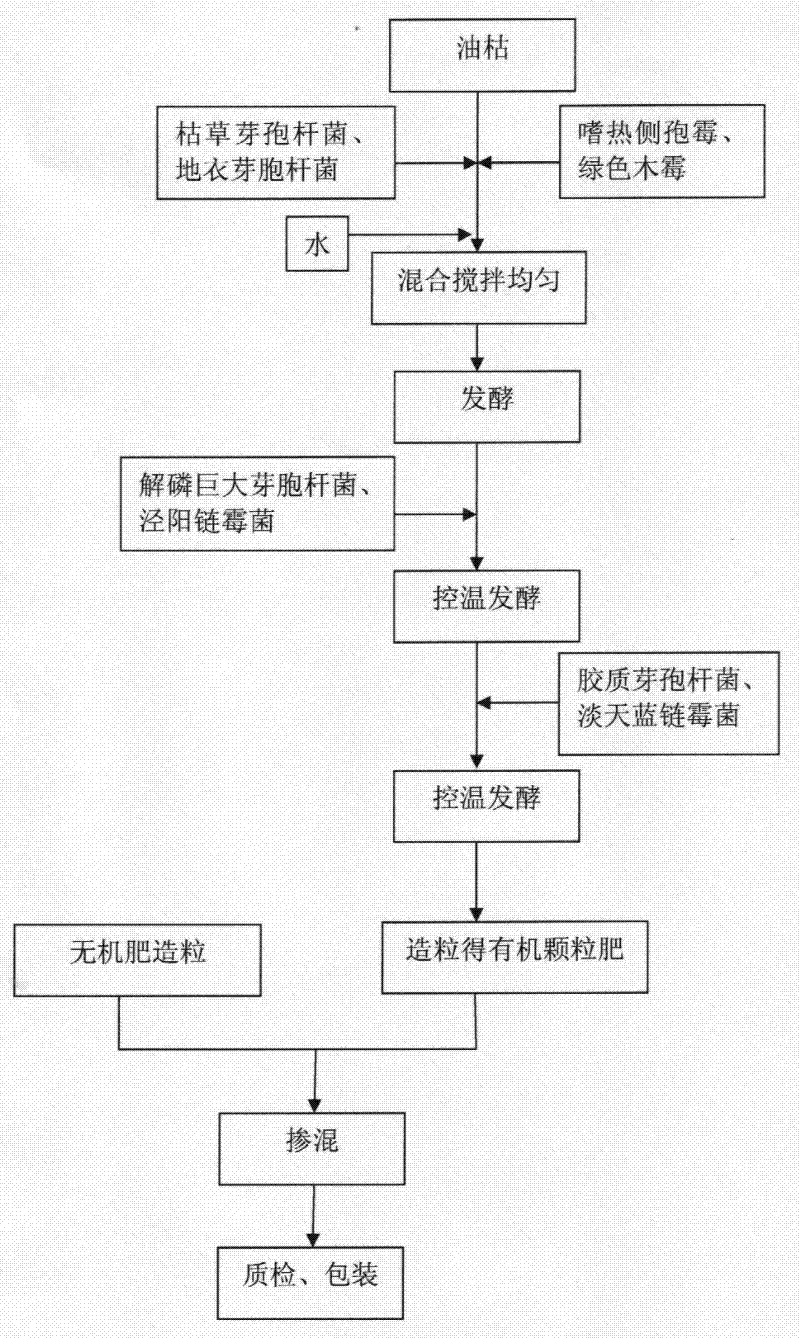

Method used

Image

Examples

Embodiment 1

[0038] Example 1: The characteristic fertilizer for tobacco provided by the present invention, the production method comprises the following steps:

[0039] A. Put the oily bacteria with a water content of 45% and a particle size > 40 mesh into the fermentation tank, add Bacillus subtilis and Bacillus licheniformis which account for 3% of the weight percentage of the oily bacteria and 5% of the oily bacteria. Stir and mix evenly for Thermosporidium and Trichoderma viride, let stand for fermentation for 24 hours, after the temperature reaches 45°C, use intermittent forced ventilation to supply oxygen through turning and throwing equipment, during which the temperature should not exceed 60°C, and turn over the material to cool down after 5 days to 45°C;

[0040] B. Add Bacillus megaterium and Streptomyces jingyang that account for 4% of the material by weight in the material obtained by fermentation in step A, and continue to ferment for 60 hours. The whole process keeps the m...

Embodiment 2

[0045] Example 2: The characteristic fertilizer for tobacco provided by the present invention, the production method comprises the following steps:

[0046] A, put water content at 48%, particle diameter > 40 mesh oily bacteria into the fermentation tank, add Bacillus subtilis, Bacillus licheniformis and accounting for oily acidic acid weight percentage as 4% of oily acid Stir and mix evenly for Disposporum calorificus and Trichoderma viride, let stand for fermentation for 36 hours, after the temperature reaches 50°C, supply oxygen with intermittent forced ventilation through the turning and throwing equipment, during which the temperature should not exceed 60°C, and turn over the material to cool down after 4 days to 46°C;

[0047] B, adding Bacillus megaterium and Streptomyces jingyang to the material obtained by fermentation in step A and accounting for 3% by weight of the material, continued to ferment for 54 hours, and kept the material fermentation temperature at any t...

Embodiment 3

[0052] Example 3: The characteristic fertilizer for tobacco provided by the present invention, the production method comprises the following steps:

[0053] A, put water content at 50%, particle diameter > 40 mesh oily bacteria into the fermentation tank, add Bacillus subtilis, Bacillus licheniformis which account for oily weight percentage of 5%, and account for oily weight percentages of 4%. Thermosporium pyrrosum and Trichoderma viride, stir and mix evenly, leave to ferment for 48 hours, after the temperature reaches 55°C, use intermittent forced ventilation to supply oxygen through the turning and throwing equipment, during which the temperature is controlled not to exceed 60°C, after 3 days, the material is turned to cool down to 43°C;

[0054] B. Add Bacillus megaterium and Streptomyces jingyang that account for 2% of the material by weight in the material obtained by fermentation in step A, and continue to ferment for 60 hours. The whole process keeps the material fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com