Gemini cationic surfactant and preparation method thereof

A technology of surfactant and gemini surface, applied in the field of cationic surfactant and its preparation, to achieve the effect of improving surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

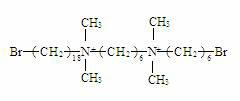

[0041] Dissolve 5g of 1-bromooctadecane and 15g of N,N,N',N'-tetramethyl-1,6-hexanediamine in 100ml of acetonitrile and toluene mixture (volume ratio 1:1), heat at 70°C 10h, the following quaternization reaction occurs, that is, two quaternary ammonium salt groups are introduced in the long-chain brominated alkanes:

[0042]

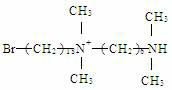

[0043] Cool to room temperature, filter, wash with ether, and dry under vacuum at 50°C. to get the intermediate product C 18 h 36 Br-N(CH 3 ) 2 -C 6 h 12 - HN(CH 3 )2 , The yield is 40%.

[0044] The above-mentioned quaternization reaction is a key point and a difficult point in the preparation of the gemini surfactant, and the reaction is difficult to carry out, resulting in a lower yield. Therefore, it is very important to adjust the process parameters such as reaction temperature, reaction time and raw material ratio. The following is a set of experimental data under the condition that the reaction time is 10h and the ratio of raw material...

Embodiment 2

[0048] Dissolve 10g of 1-bromooctadecane and 15g of N,N,N',N'-tetramethyl-1,6-hexanediamine in 85ml of acetonitrile and toluene mixture (volume ratio 1:1.5), heat at 90°C for 8h ,reaction

[0049]

[0050] Cool to room temperature, filter, wash with ether, and dry under vacuum at 50°C. Gemini surfactant intermediate C is obtained 18 h 36 Br-N(CH 3 ) 2 -C 6 h 12 - HN(CH 3 ) 2 , The yield is 38%.

[0051] The following is a set of experimental data under the condition that the reaction temperature is 90°C and the ratio of raw materials is 1:10:

[0052] Table 2. C at different reaction times 18 h 36 Br-N(CH 3 ) 2 -C 6 h 12 - HN(CH 3 ) 2 Yield of

[0053]

Embodiment 3

[0055] Dissolve 10g of 1-bromooctadecane and 15g of N,N,N',N'-tetramethyl-1,6-hexanediamine in 106ml of acetonitrile and toluene mixture (volume ratio 1:1.3), heat at 80°C for 10h ,reaction

[0056]

[0057] Cool to room temperature, filter, wash with ether, and dry under vacuum at 50°C. Gemini surfactant intermediate C is obtained 18 h 36 Br-N(CH 3 ) 2 -C 6 h 12 - HN(CH 3 ) 2 , with a yield of 45%.

[0058] The following is a set of experimental data under the condition that the reaction temperature is 90°C and the reaction time is 10h:

[0059] Table 3 C under different raw material ratios 18 h 36 Br-N(CH 3 ) 2 -C 6 h 12 - HN(CH 3 ) 2 Yield of

[0060] Raw material ratio (molar ratio) Theoretical yield / g Actual output / g Yield / % 1:2 5.091 1.905 21.51 1:5 5.093 2.268 44.53 1:10 5.071 1.895 37.37 1:15 5.086 1.444 28.39 1:20 5.090 1.024 20.12

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com