Method for preparing binary copolymer retarder for oil and gas well cementing

A binary copolymer, well cementing technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of complex raw materials and the effect of cement retarder retarding effect, etc., and achieve simple and good compatibility of raw materials The effect of sex, excellent technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

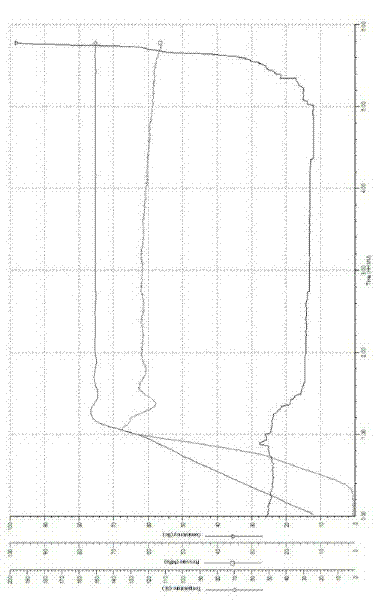

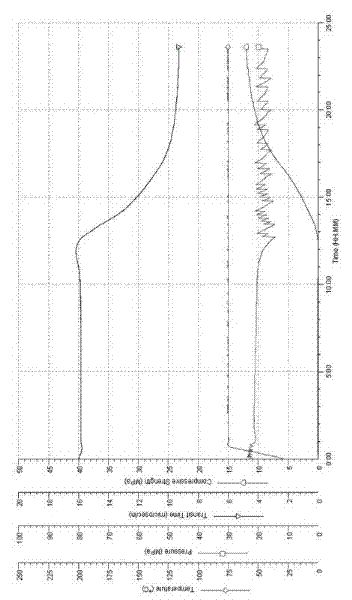

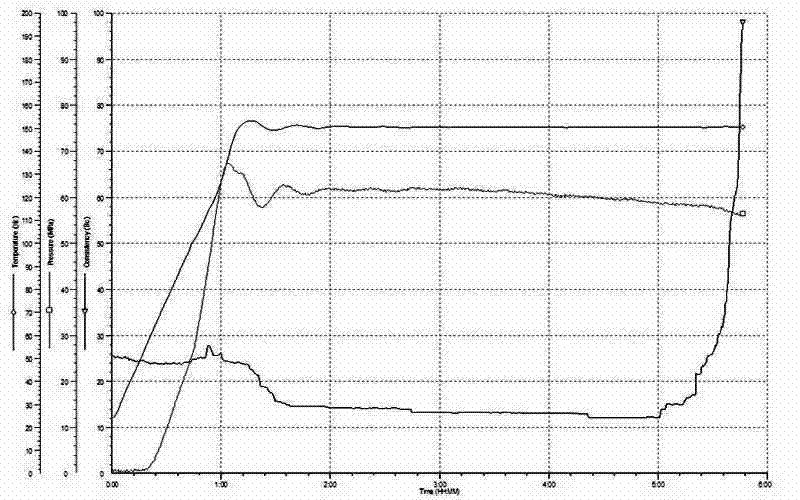

Image

Examples

Embodiment 1

[0038] The invention discloses a method for preparing a binary copolymer retarder for oil and gas well cementing. The steps include:

[0039] (1) Weigh 2-acrylamide-2-methylpropanesulfonic acid and itaconic acid according to the mass ratio of 73~75:25~27 and dissolve them in 200% deionized water of the total monomer mass;

[0040] (2) Adjust the pH value of the solution in step (1) to 5-6 with a NaOH solution of 50% mass volume concentration;

[0041] (3) Put the solution obtained in step (2) into a three-necked flask, conduct a constant temperature water bath, and raise the temperature to 60~65°C;

[0042] (4) Add dropwise an initiator accounting for 1.0% to 2.0% of the total monomer mass to the solution obtained in step (3), and continue the reaction for 4 to 6 hours to obtain the final product.

[0043] Compared with the existing similar technology, the present invention has the following technical advantages:

[0044] The method is aqueous solution polymerization, and th...

Embodiment 2

[0049] The preparation method of binary polymer retarder of the present invention is as follows:

[0050] According to the mass ratio of 75:25, respectively weigh 2-acrylamide-2-methylpropanesulfonic acid and itaconic acid and dissolve them in 200% deionized water of the total monomer mass; adjust the pH value with NaOH solution of 50% mass volume concentration to 6; put the solution in a three-necked flask with a thermometer and a stirrer, and raise the temperature to 60°C in a constant temperature water bath, and dropwise add potassium persulfate, an initiator accounting for 2.0% of the total monomer mass, to the solution within 30 minutes, and continue the reaction for 4 hours. Get the final product, binary copolymer retarder.

[0051] Effect of the present invention is:

[0052] The retarder can effectively prolong the thickening time of cement slurry in the temperature range of 50-180°C. Taking Jiajiang G grade cement as an example, according to the GB / T19139-2003 standar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com