Soluble functional polyimide based on fluorene structure as well as preparation method and application thereof

A polyimide, soluble technology, applied in the field of soluble functional polyimide and its preparation, can solve the problem of single variety, and achieve the effects of simple preparation process, excellent photoluminescence, and excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

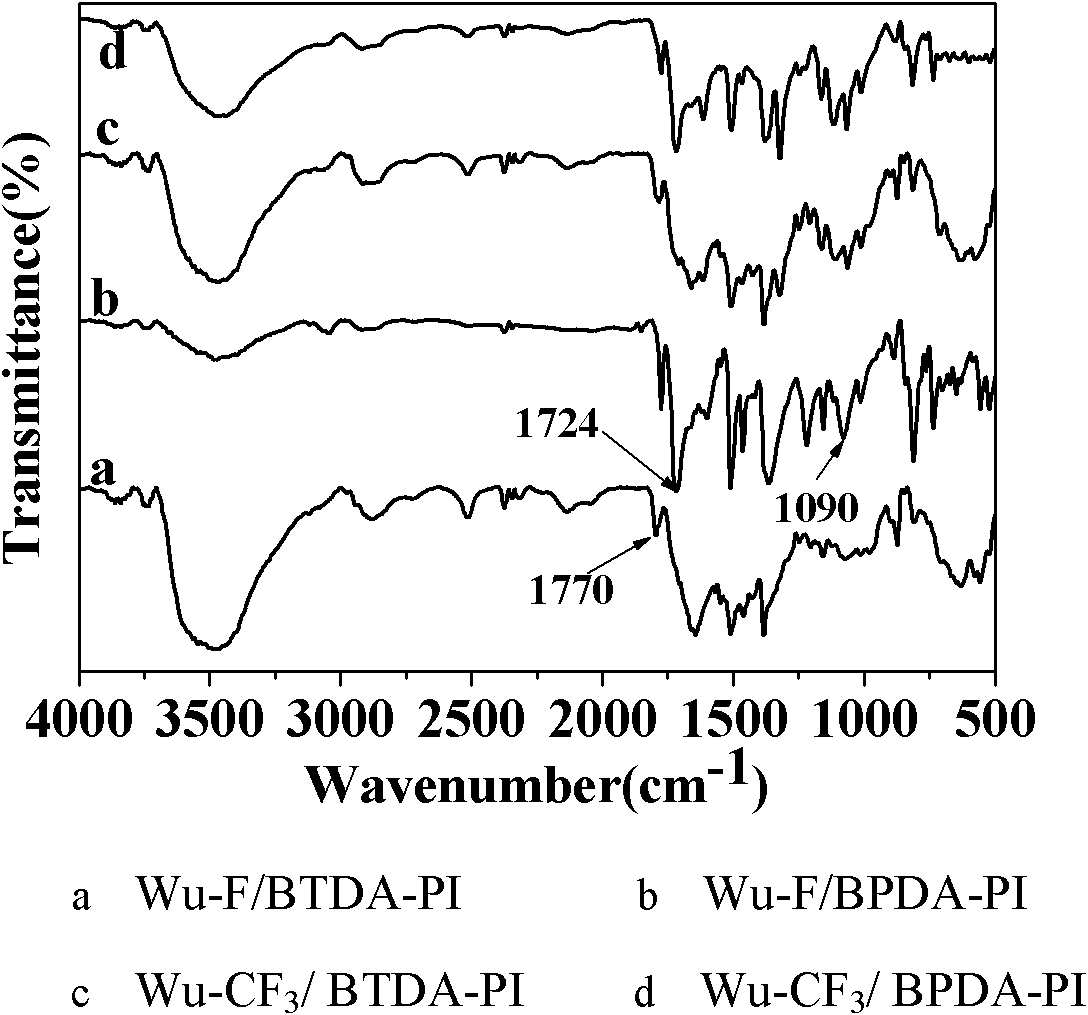

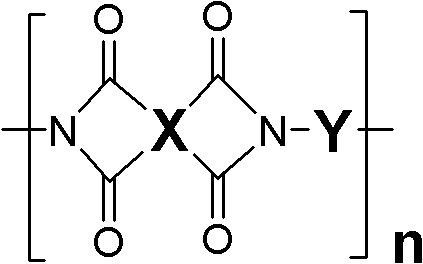

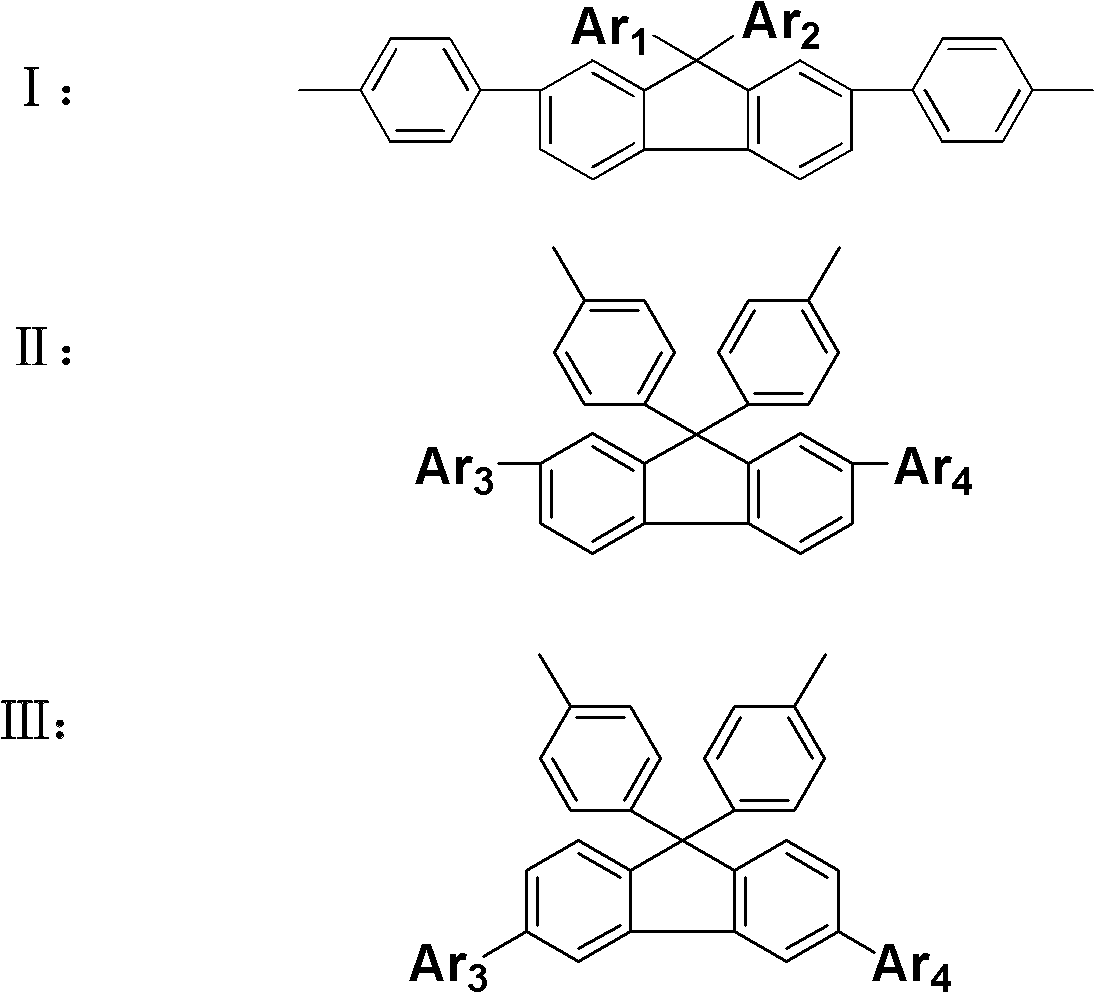

Method used

Image

Examples

Embodiment 1

[0032] At room temperature, mix 5.3661g (0.01mol) 4-(9-(4-aminophenyl)-2,7-bis(4-fluorophenyl)-9H-fluoren-9-yl)benzenamine(Wu-F) and 57.3g( 60.7ml) N,N-dimethylformamide was added to a 100ml three-necked flask, argon was passed through, stirred, and after complete dissolution, add 3.2223g (0.01mol) 3,3′,4,4′-Benzophenonetetracarboxylic dianhydride (3,3',4,4'-benzophenonetetracarboxylic dianhydride, BTDA), continue to stir and react for 6 hours to obtain a homogeneous transparent viscous polyamic acid solution. Then the polyamic acid solution was scraped on the glass plate, and the glass plate was placed in a vacuum oven and vacuumed. The heating program was as follows: the room temperature was raised to 100°C and the temperature was kept constant throughout the process for 1h→100°C was raised to 200°C and then the temperature was kept constant The process is 1h→200°C to 350°C and the temperature is kept constant for 1.5h. The polyimide film can be taken out after cooling. The ...

Embodiment 2

[0036] At room temperature, mix 5.3661g (0.01mol) 4-(9-(4-aminophenyl)-2,7-bis(4-fluorophenyl)-9H-fluoren-9-yl)benzenamine(Wu-F) and 511g(58.4 ml) N,N-Dimethylformamide was added to a 100ml three-necked flask, argon was passed through, stirred, and after it was completely dissolved, 2.9027g (0.01mol) 4,4′-Biphthalic Anhydride was added. Anhydride, BPDA), continue to stir and react for 6 hours to obtain a homogeneous transparent viscous polyamic acid solution. Then the polyamic acid solution was scraped on the glass plate, and the glass plate was placed in a vacuum oven and vacuumed. The heating program was as follows: the room temperature was raised to 100°C and the temperature was kept constant throughout the process for 1h→100°C was raised to 200°C and then the temperature was kept constant The process is 1h→200°C to 350°C and the temperature is kept constant for 1.5h. The polyimide film can be taken out after cooling. The 5% thermal weight loss temperature of the polyimide ...

Embodiment 3

[0040] Prepare the polyamic acid solution in the same manner as in Example 2, and then use chemical imidization to prepare polyimide. The steps are as follows: add 5 mL of acetic anhydride to the obtained polyamic acid solution, continue to stir, and then slowly add 2.5 mL of three Ethylamine, heated to 70°C, continue to stir for 6h, and then the solution is scraped onto a clean glass plate, then the glass plate is placed in a vacuum oven, vacuumed, and dried at 100°C for 12h. After cooling, the polyimide film can be taken out. The 5% weight loss temperature of the polyimide film is 569° C., and the wavelength of the strongest fluorescence peak is 540 nm. The infrared spectrum of the polyimide film is the same as that of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com