Multifunctional fabric capable of shielding ultraviolet rays and having lasting superhydrophobic performance and preparation method thereof

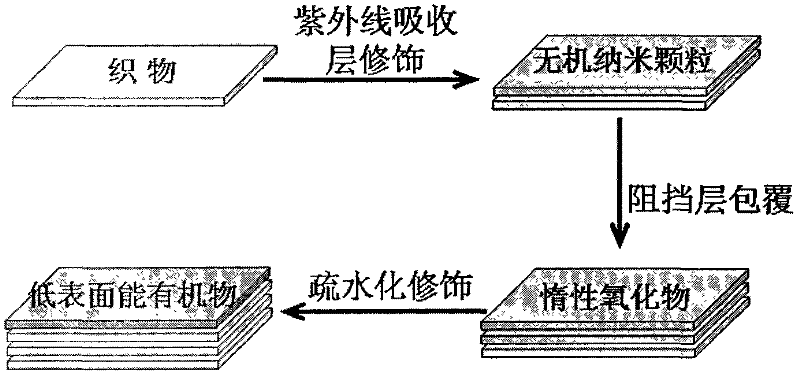

An ultraviolet and super-hydrophobic technology, applied in textiles, papermaking, fiber processing, etc., can solve the problem of inability to obtain super-hydrophobic properties, and achieve the effects of durable super-hydrophobicity, low cost, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Step 1: soak the cleaned fabric in the sol of ZnO nanoparticles prepared by sol-gel method for 1 hour, take it out and put it into a reaction kettle with 1 mmol / L of zinc acetate solution after drying, 80 ℃ for 1 hour, after the reaction is complete, the sample is taken out, washed, and dried at 20 ℃ for later use. The obtained fabric is modified with ZnO nanoparticles.

[0018] Zinc acetate can be replaced with zinc nitrate, zinc chloride, zinc sulfate, zinc acetylacetonate, etc.

[0019] Step 2: immerse the fabric prepared in step 1 in the PEI polyelectrolyte solution, soak for 5 minutes, take it out and then immerse it in a 0.1 mmol / L sodium silicate solution, soak for 5 minutes, wash it after taking it out, dry it, Obtain ZnO nanoparticles coated with SiO 2 monolayer fabric.

[0020] Sodium silicate can be replaced by tetraethyl orthosilicate, 3-aminopropyltriethoxysilane, etc., and PEI can be replaced by PDDA.

[0021] Step 3: Put the fabric prepared in step 2 ...

Embodiment 2

[0025] Step 1: change the soaking time of the sol in Example 1 into 12 hours, change the concentration of zinc acetate into 50 mmol / liter, change the reaction temperature into 100°C, change the reaction time into 12 hours, and change all the other reaction processes and conditions into constant, A fabric modified with ZnO nanoparticles with increased size and distribution density of ZnO nanoparticles is obtained.

[0026] Step 2: Repeat the reaction operation 10 times on the basis of Example 1, that is, perform 10 alternate depositions of PEI and sodium silicate to obtain multilayer SiO 2 Particle layer coated ZnO nanoparticles modified fabric.

[0027] Step 3: Change the reaction temperature in Example 1 to 120°C, change the reaction time to 2 hours, and keep the rest of the reaction process and conditions unchanged to obtain a hydrophobic functionalized fabric

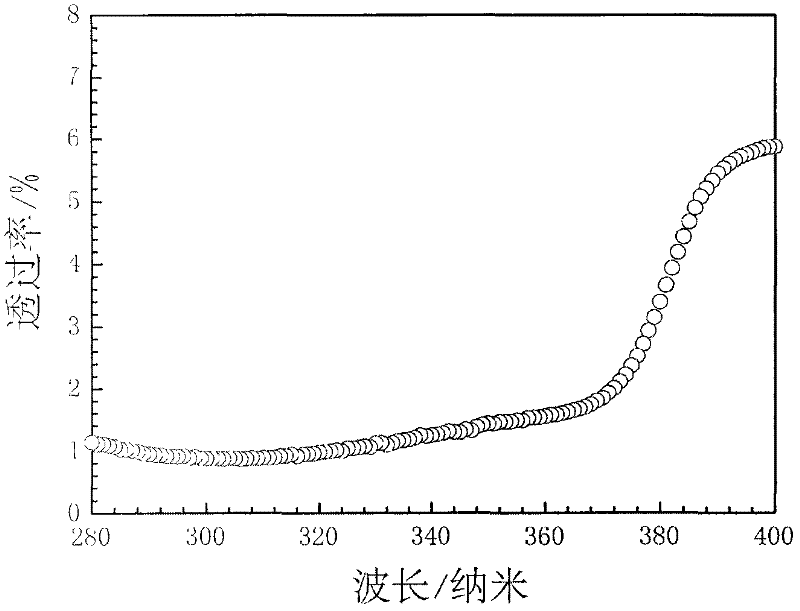

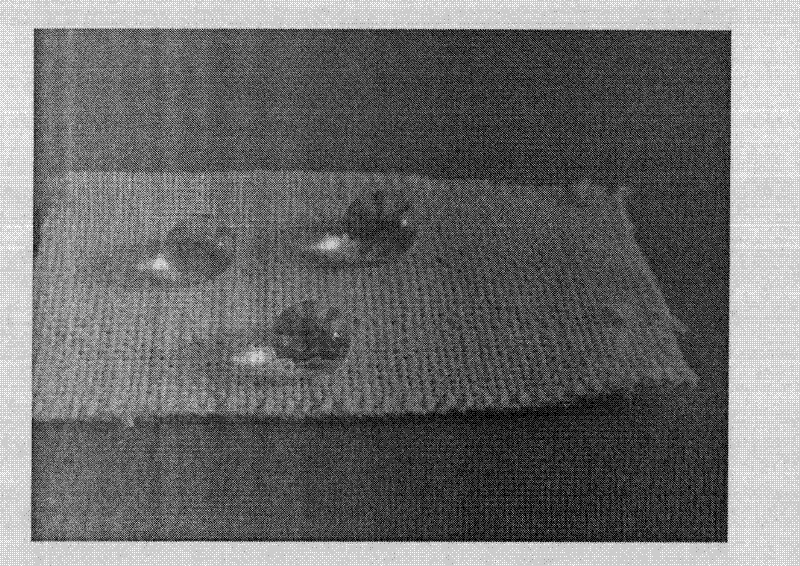

[0028] Step 4: Carry out the transmittance spectrum test to the fabric with an ultraviolet-visible absorption spe...

Embodiment 3

[0030]Step 1: change the soaking time of the sol in Example 1 into 24 hours, change the concentration of zinc acetate into 0.5 mol / liter, change the reaction temperature into 150°C, change the reaction time into 24 hours, and change the remaining reaction process and conditions to obtain ZnO nanoparticle modified fabric with further increased ZnO nanoparticle size and distribution density.

[0031] Step 2: Replace the concentration of sodium silicate in Example 1 with 100 mmol / L, replace the soaking time with 12 hours, and keep the rest of the reaction process and conditions unchanged to obtain dense SiO coated on the surface of ZnO nanoparticles 2 monolayer fabric.

[0032] Step 3: Change the reaction temperature in Example 1 to 150° C., change the reaction time to 3 hours, and keep the rest of the reaction process and conditions unchanged to obtain a hydrophobic functionalized fabric.

[0033] Step 4: The transmission spectrum test of the fabric is carried out with an ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com