Method for measuring electrostrictive coefficient by using multi-beam laser heterodyne quadratic harmonic method

A laser heterodyne and second harmonic technology, applied in the measurement of electricity, measurement of electrical variables, measurement devices, etc., can solve the problems of poor laser difference frequency signal collection effect, slow signal processing operation speed, and low measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

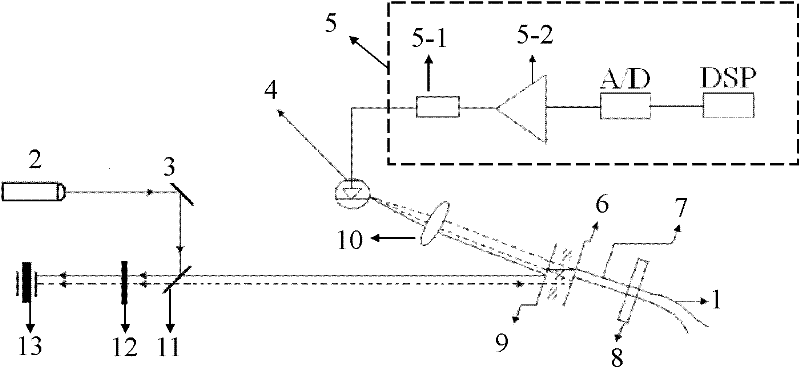

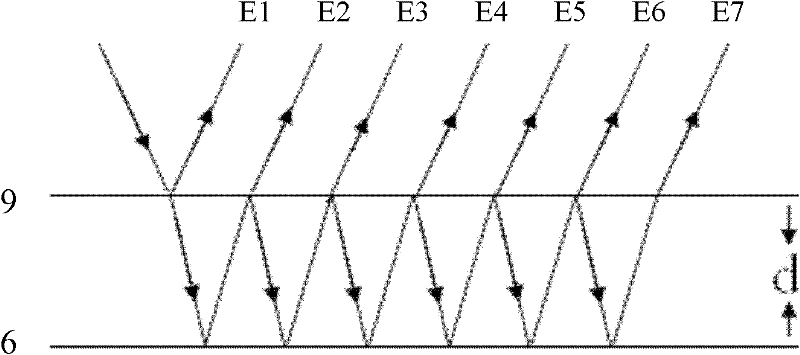

[0058] Specific implementation mode one, combination figure 1 In this specific embodiment, the method for measuring the electrostriction coefficient by the multi-beam laser heterodyne second-harmonic method is implemented based on the system for measuring the electrostriction coefficient by the multi-beam laser heterodyne second-harmonic method. By H 0 Solid-state laser 2, quarter wave plate 12, galvanometer 13, first plane mirror 3, polarizing beam splitter PBS11, converging lens 10, thin glass plate 9, second plane mirror 6, piezoelectric ceramic to be tested Tube 7, two-dimensional adjustment frame 8, high-voltage power supply, photoelectric detector 4 and signal processing system 5;

[0059] H 0 The linearly polarized light emitted by the solid-state laser 2 is reflected by the first plane mirror 3 and then enters the polarization beam splitter PBS11. The light beam reflected by the polarization beam splitter PBS11 is transmitted by the quarter wave plate 12 and then enters th...

specific Embodiment approach 2

[0111] The second embodiment is different from the method for measuring the electrostriction coefficient by the multi-beam laser heterodyne second harmonic method described in the first embodiment in that the piezoelectric ceramic tube 7 to be tested uses PZT piezoelectric ceramic Body production.

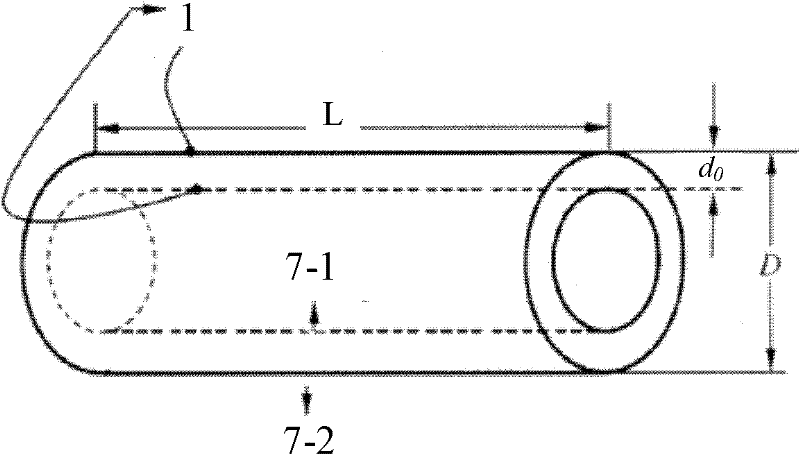

[0112] The piezoelectric body to be tested first uses a circular tube-shaped piezoelectric ceramic, its shape and structure are as figure 1 Shown. It is made of lead zirconate titanate (PZT). The inner and outer surfaces of the tube are plated with silver. As an electrode, the lead wire can be connected to apply an external voltage to it. Experiments show that when a voltage is applied to its outer surface When the surface is grounded), the tube is stretched, on the contrary, when a negative voltage is applied, the tube is shortened.

[0113] Let E represent the electric field strength of the radial electric field formed between the inner and outer surfaces of the tube after applying a...

specific Embodiment approach 3

[0120] Embodiment 3 The difference between this embodiment and the method for measuring electrostriction coefficient by the multi-beam laser heterodyne second harmonic method described in the first embodiment is that the multi-beam laser heterodyne second harmonic method measures electricity In the system of stretching coefficient, the signal processing system 5 is composed of a filter circuit 5-1, a preamplifier circuit 5-2, an analog-to-digital conversion circuit A / D and a digital signal processor DSP. The electric signal output by the photodetector 4 is filtered and sent to the preamplifier circuit 5-2. The signal amplified by the preamplifier circuit 5-2 is output to the analog-digital conversion circuit A / D. The digital conversion circuit A / D sends the converted signal to the digital signal processor DSP.

[0121] The following specific simulation experiments verify the effects of the present invention: figure 1 The shown multi-beam laser heterodyne second harmonic measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com