Method for synchronically synthesizing two ZnO nanostructures

A nanostructure and nanosheet technology is applied in the field of simultaneous synthesis of two ZnO nanostructures, which can solve the problems of complicated preparation process and low efficiency, and achieve the effects of high purity, easy operation and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] A kind of embodiment of the present invention is: a kind of method synchronously synthesizing two kinds of ZnO nanostructures, and its concrete practice is:

[0033] a. Cleaning of fluorine-doped SnO2 transparent conductive glass

[0034] (1) the SnO2 transparent conductive glass doped with fluorine that the square surface resistance is 14 ohms, in the HCl solution of 0.1M, ultrasonic 30min removes inorganic ion; (2) after cleaning with deionized water, put into 5% Washing powder solution, ultrasonic at 70°C for 2 hours; (3) Ultrasonic with isopropanol solvent for 30 minutes; (4) Wash with deionized water and dry;

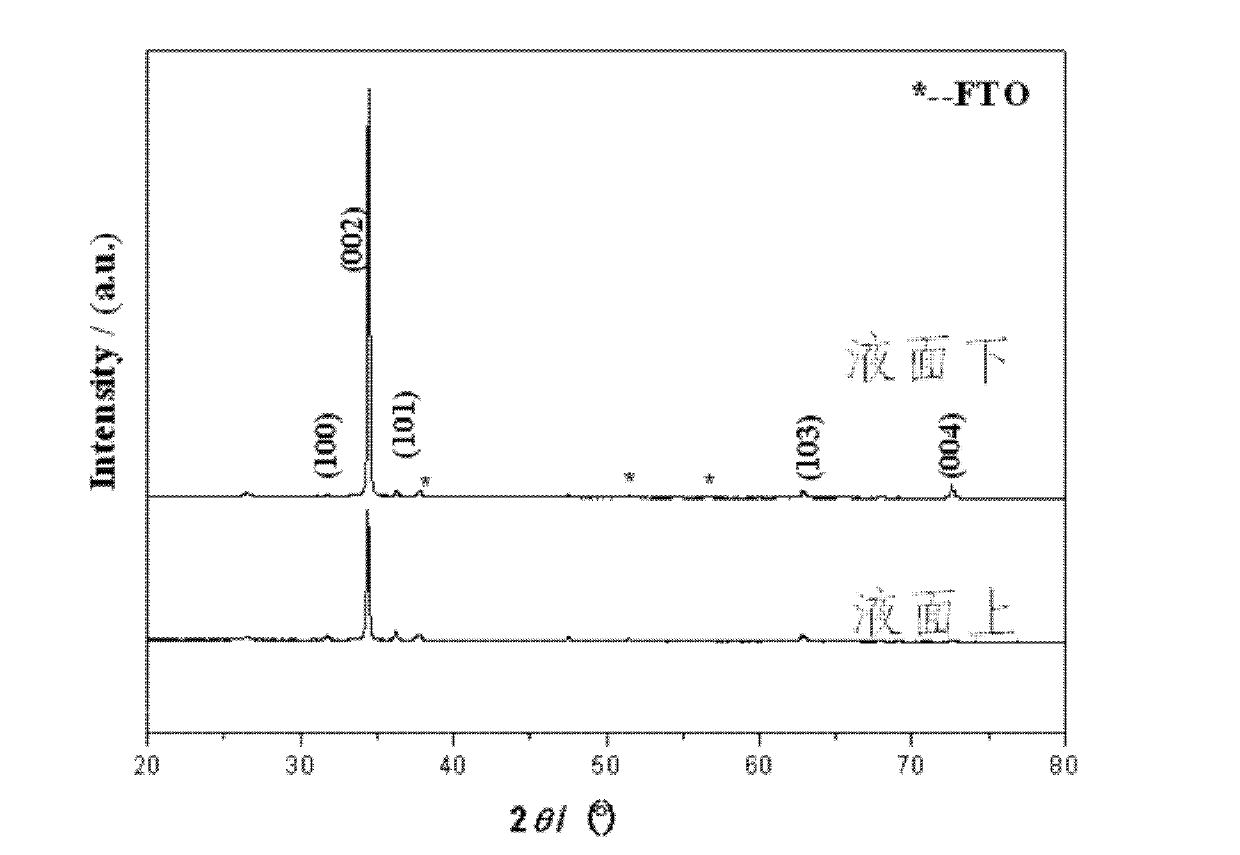

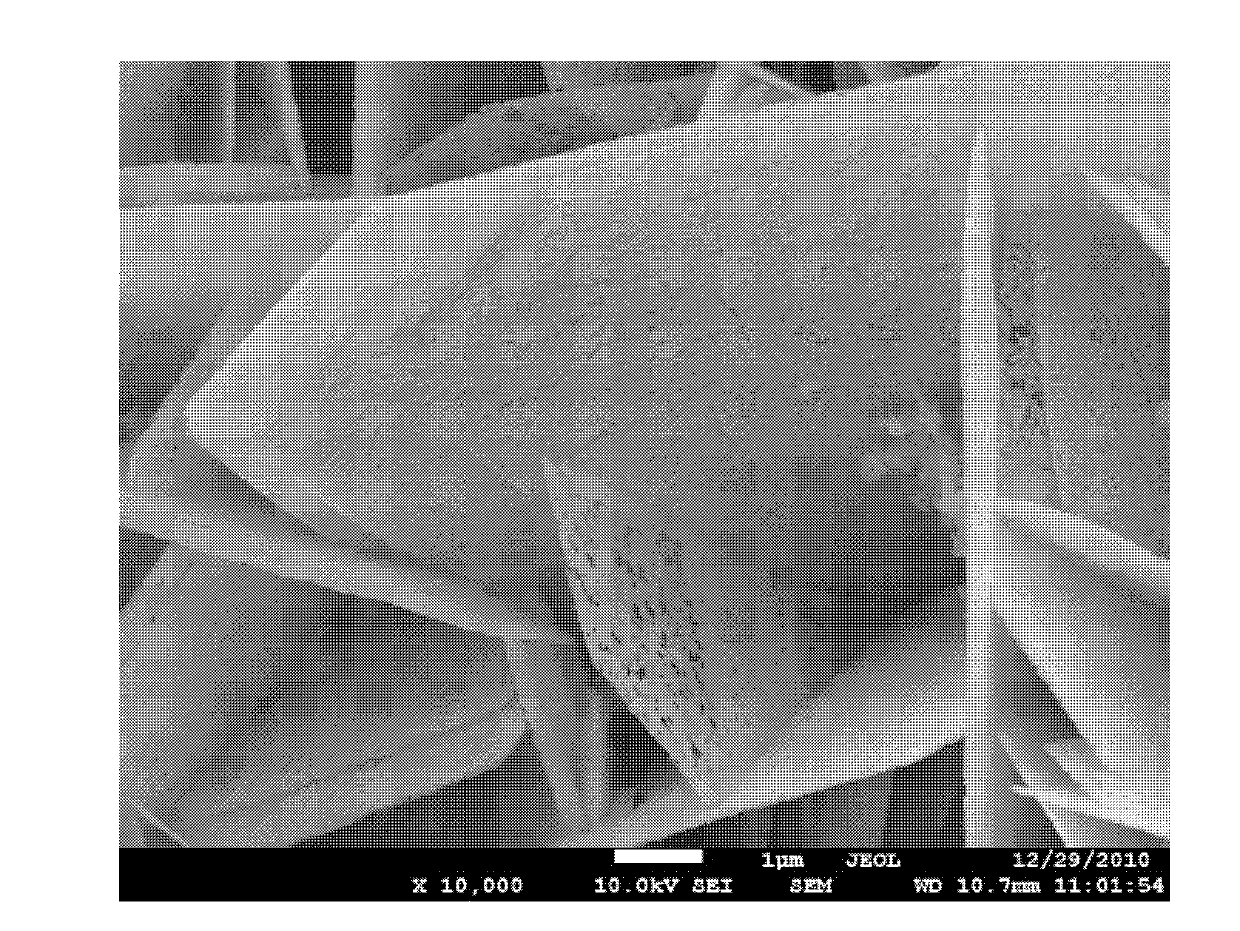

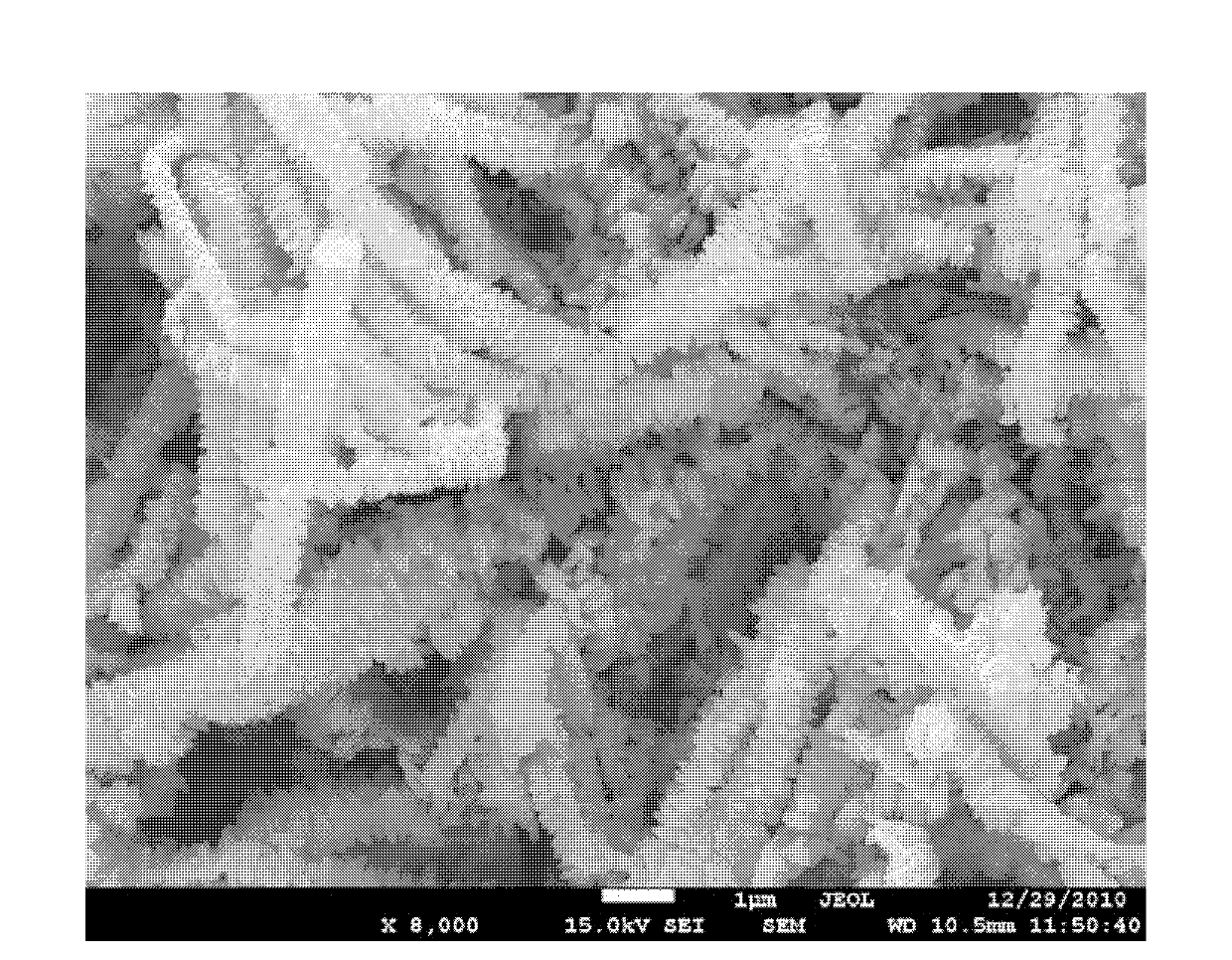

[0035] b. Preparation of ZnO hollow nanosheets and nanorods by electrodeposition

[0036] A three-electrode electrolytic cell system is adopted, the platinum sheet is the auxiliary electrode, the saturated calomel electrode is the reference electrode, the cleaned fluorine-doped SnO2 transparent conductive glass is the working electrode, and the electrolyte ...

Embodiment 2

[0042] The specific approach in this example is:

[0043] a. Cleaning of fluorine-doped SnO2 transparent conductive glass

[0044] (1) the SnO2 transparent conductive glass doped with fluorine that the square surface resistance is 10 ohms, in the HCl solution of 0.3M, ultrasonic 40min removes inorganic ion; (2) after cleaning with deionized water, put into 10% Washing powder solution, ultrasonic at 70°C for 2.5 hours; (3) Ultrasonic with isopropanol solvent for 40 minutes; (4) Wash with deionized water and dry;

[0045] b. Preparation of ZnO hollow nanosheets and nanorods by electrodeposition

[0046] A three-electrode electrolytic cell system is adopted, the platinum sheet is the auxiliary electrode, the saturated calomel electrode is the reference electrode, the cleaned fluorine-doped SnO2 transparent conductive glass is the working electrode, and the electrolyte is Zn(NO 3 ) 2 A mixed solution with a concentration of 0.3M and KCl; the electrolytic cell was deposited for ...

Embodiment 3

[0051] The specific approach in this example is:

[0052] a. Cleaning of fluorine-doped SnO2 transparent conductive glass

[0053] (1) with the SnO2 transparent conductive glass doped with fluorine that the square surface resistance is 12 ohms, in the HCl solution of 0.2M, ultrasonic 35min removes inorganic ion; (2) after cleaning with deionized water, put into 8% Washing powder solution, ultrasonic at 70°C for 2.3 hours; (3) Ultrasonic with isopropanol solvent for 38 minutes; (4) Wash with deionized water and dry;

[0054] b. Preparation of ZnO hollow nanosheets and nanorods by electrodeposition

[0055] A three-electrode electrolytic cell system is adopted, the platinum sheet is the auxiliary electrode, the saturated calomel electrode is the reference electrode, the cleaned fluorine-doped SnO2 transparent conductive glass is the working electrode, and the electrolyte is Zn(NO 3 ) 2 The concentration of KCl and KCl are both 0.3M mixed solution; the electrolytic cell is dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com