Preparation method of glucolactone

A technology of gluconolactone and glucose, which is applied in the field of food additive production, can solve the problems of long production cycle, high production cost and high energy consumption, and achieve the effects of reduced production cost, high yield and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

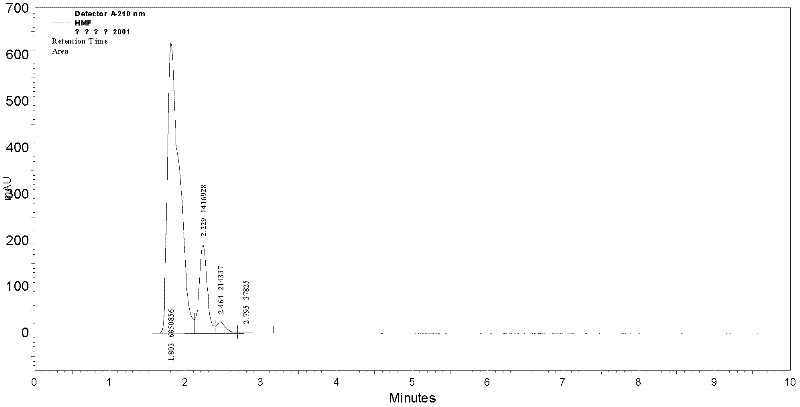

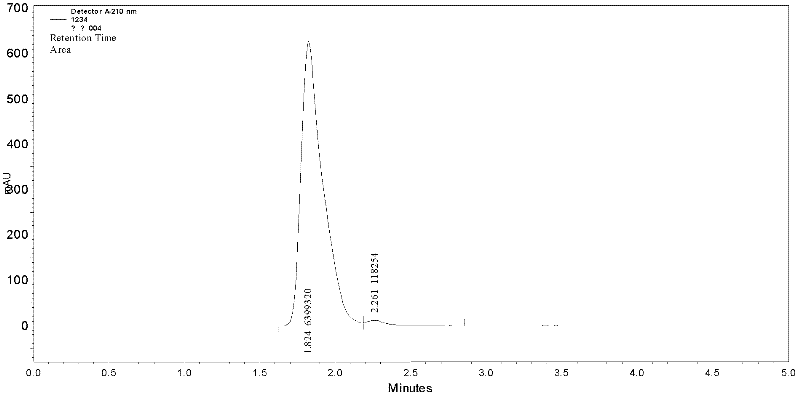

[0024] Add 100g of glucose into a 1L measuring cylinder, add deionized water to make the volume to 200ml, and obtain a glucose solution; insert a ventilation pump and a UV lamp with a power of 40W into the glucose solution in the measuring cylinder; put the measuring cylinder into the reaction device, and set the temperature At 40°C, carry out the catalytic oxidation reaction under the condition of feeding air and stirring; during the reaction process, 103 ml of hydrogen peroxide with a mass fraction of 30% was added for 0.6 hours, and after the catalytic oxidation reaction for 2 hours, filter to obtain 280 ml of gluconic acid solution. At this point, the conversion rate of glucose was measured to reach 99.1%, as figure 1 As shown, the peak at 1.801min is the target product gluconic acid, and it can be seen that the selectivity of the generated gluconic acid is better by integral conversion, reaching 90%.

[0025] Concentrate the gluconic acid solution obtained above under red...

Embodiment 2

[0027] Add 5kg of glucose into a 30L reaction pot, add deionized water to make the volume to 16L, and obtain a glucose solution; insert the ventilation pump and 8 UV lamps with a power of 40W into the glucose solution evenly; set the temperature of the reaction pot at 50 ℃, carry out the catalytic oxidation reaction under the condition of feeding air and stirring; during the reaction process, 2.58L hydrogen peroxide with a mass fraction of 30% was added for 0.6 hours, and after the catalytic oxidation reaction was carried out for 3 hours, filtered to obtain 18.6L gluconic acid solution. At this time, it was measured that the conversion rate of glucose reached 98.3%, and the selectivity of the generated gluconic acid reached 88.6%.

[0028] Concentrate the gluconic acid solution obtained above under reduced pressure at 75°C to a solid content of 80%, then add gluconolactone seed crystals with a theoretical mass content of gluconolactone of 0.3%, and crystallize in a stirring cry...

Embodiment 3

[0030] Add 40kg of glucose into a 200L reaction pot, add deionized water to 66L to obtain a glucose solution; insert a ventilation pump and 10 UV lamps with a power of 200W into the glucose solution; set the temperature of the reaction pot at 60°C , carry out the catalytic oxidation reaction under the condition of feeding air and stirring; during the reaction process, 42L mass fraction of 30% hydrogen peroxide was added for 0.3 hours, after the catalytic oxidation reaction was carried out for 1 hour, filtered to obtain 103L gluconic acid solution. At this time, it was measured that the conversion rate of glucose reached 97.5%, and the selectivity of the generated gluconic acid reached 88.2%.

[0031] Concentrate the gluconic acid solution obtained above under reduced pressure at 80°C to a solid content of 85%, then add gluconolactone seed crystals with a theoretical mass content of gluconolactone of 0.1%, and crystallize in a stirring crystallizer for 30 hours. Control the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com