Construction method of genetic engineering strain for high expression and easy purification of beta-mannanase

A technology of genetically engineered strains and mannanase, which is applied in the fields of molecular biology and genetic engineering, can solve problems such as cost expenditure, difficult separation and purification of highly expressed products, and complicated separation and purification, so as to improve production performance and nutritional value , eliminate the effect of anti-nutritional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

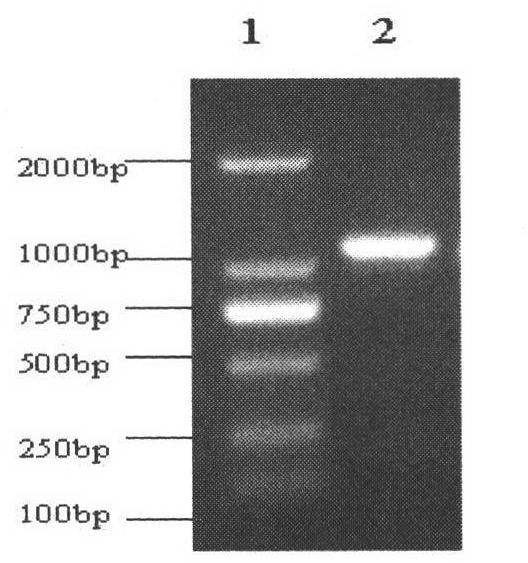

[0012] Example 1: Cloning of β-mannanase gene

[0013] [1] According to the gene sequence published by NCBI, use DNAMAN software to design primer P 1 And P 2 .

[0014] P 1 : 5’-ATCGGATCCATGTTTAAGAAACATACGAT-3’

[0015] P 2 : 5’-GGCACGCGTGTGGTGGTGGTGGTGGTGCTCAACGATTGGCGTTA-3’

[0016] Extraction of chromosomal DNA of Bacillus subtilis JNA (preservation number CTCC M 2009200). Extraction method: Use an inoculating loop to pick a single colony from a fresh Bacillus subtilis JNA plate and inoculate it in LB liquid medium, shake overnight at 37°C, and take 400 μl the next day Centrifuge the bacteria solution at 8000r / min for 3min, discard the supernatant, wash the cells once with 0.5ml TE, centrifuge and discard the supernatant, then fully suspend the cells in 0.5ml TE, add 50μl 10mg / ml lysozyme solution, mix well, 37℃ Water bath for 2-3h, add 100μl 10% SDS, mix well, keep at 37°C for 30min, add 50μl 10mg / ml proteinase K, react at 65°C for 3h, during the mixing every half an hour, add eq...

Embodiment 2

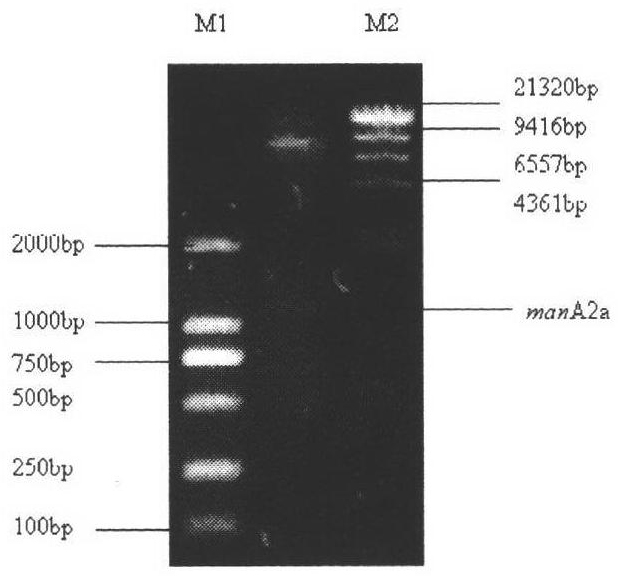

[0018] Example 2: Construction of recombinant plasmid pMA5-manA2a and transformation of Bacillus subtilis 168

[0019] Construct the recombinant vector pMA5-manA2a, the PCR product of β-mannanase gene obtained in Example 1 [2] and the plasmid pMA5 were simultaneously digested with BamH I and Mlu I, and then connected with the gel recovery box. Ligation system: target gene digestion product 7.5μl, pMA5 digestion product 0.5μl, T4DNA ligase buffer 1μl, T4DNA ligase 1μl, ligation at 16°C overnight. Transform the ligated recombinant plasmid pMA5-manA2a into competent Bacillus subtilis168. Transformation method: pick Bacillus subtilis 168 and inoculate it in 5ml LB and cultivate overnight at 37°C on a shaker; take 100ul of the bacterial solution cultured overnight and inoculate it with a 50ml centrifuge In the 5ml SPI medium in the tube, culture on a shaker at 37℃. When the strain grows to the end of the logarithmic phase, quickly inoculate 200μl into 2ml SPII medium, culture at 37℃ o...

Embodiment 3

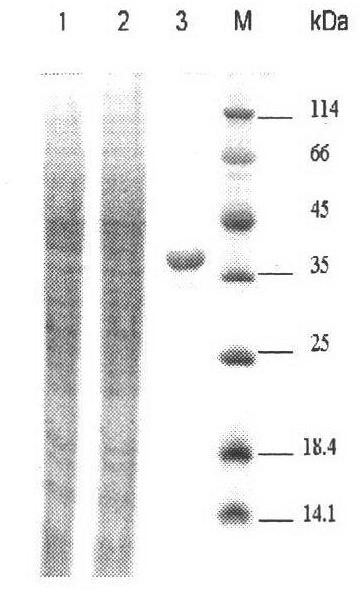

[0020] Example 3: Expression detection and purification of β-mannanase-producing recombinant strain BPM1003

[0021] The obtained β-mannanase-producing recombinant strain BPM1003 was inoculated into a new 50ml LB liquid medium at an inoculum of 2%, the fermentation broth was taken, centrifuged at 4°C at 8000r / min for 5 minutes, and the pellet was discarded, and the supernatant was passed through Ni-NTA column to obtain the pure enzyme solution, the obtained pure enzyme solution 10ul plus the corresponding loading Marker as the sample for SDS-PAGE detection, in which SDS-PAGE uses 5% separation gel and 15% concentrated gel, using discontinuous Vertical electrophoresis, stained with Coomassie Brilliant Blue R250, and Bacillus subtilis 168 containing empty plasmid pMA5 as a blank control (such as image 3 ). The purified enzyme activity was 3768.7u / ml, which was 4.2 times the enzyme activity of the crude enzyme solution, and the specific enzyme activity reached 4579.2u / mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com