Method for preparing all-vanadium ion redox flow battery electrolyte

A liquid flow battery and electrolyte technology, applied in the direction of regenerative fuel cells, etc., can solve the problems of poor stability and low electrolyte concentration of vanadium batteries, and achieve the effects of good stability, easy operation, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

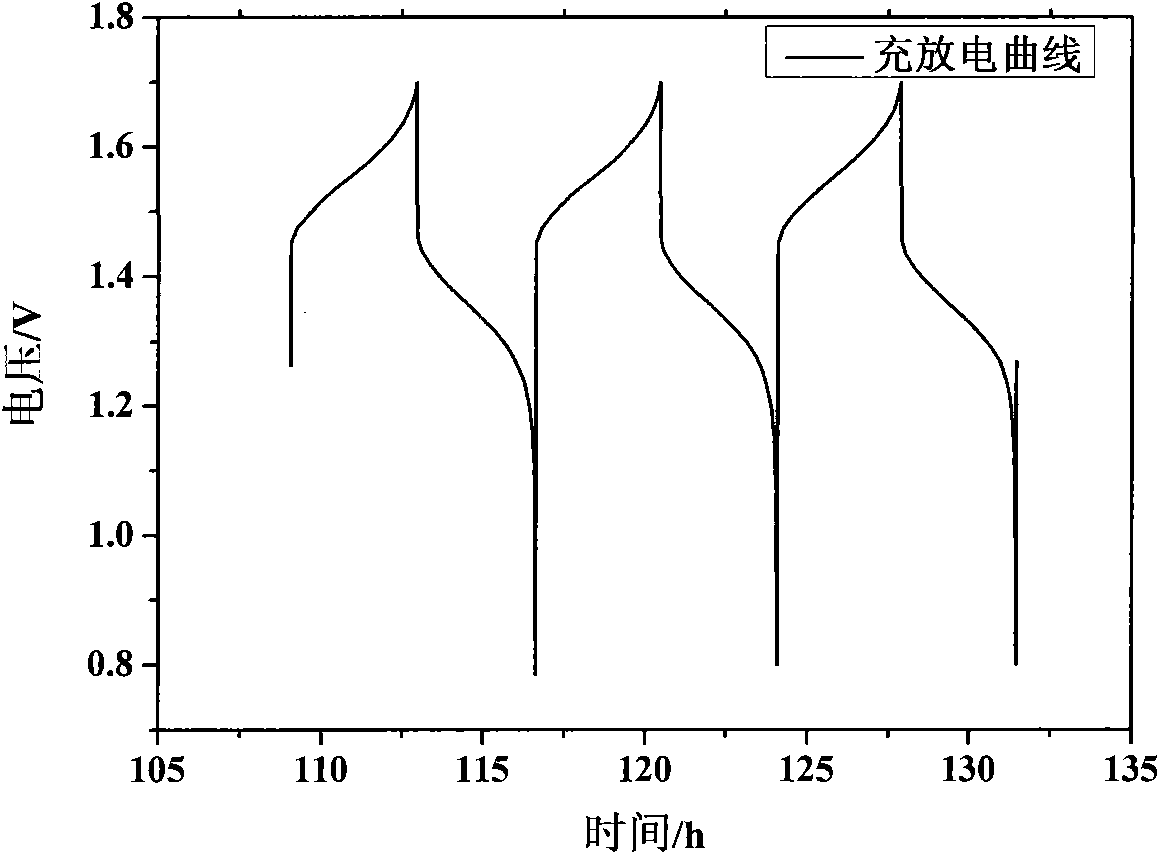

Embodiment 1

[0025] Dissolve 0.5 mol of methanesulfonic acid, 0.5 mol of vinyl sulfonic acid, and 0.5 mol of propynyl sulfonic acid with 2L of deionized water to prepare an aqueous solution containing organic acids. The organic acid is heated during the dissolution process, and the heating temperature is 80°C. Then, weigh 3 mol of vanadyl sulfate and add an aqueous solution containing organic acid as a diluent. After all of it is dissolved, pour it into a volumetric flask and dilute to 1000 mL to obtain a 3mol / L vanadyl sulfate solution. Ultrasonic treatment was carried out during the dissolution of vanadyl sulfate, and the treatment time was 60 minutes. Graphite is used as the anode and cathode materials, the concentration of the anode and cathode solutions are both 3mol / L vanadyl sulfate and 1.5mol / L organic acid aqueous solution, and the charging current density is 30mA / cm 2 , The discharge current density is 30mA / cm 2 , The voltage efficiency is 85%, the Coulomb efficiency is 93%, and t...

Embodiment 2

[0028] Dissolve 0.5 mol of ethyl sulfonic acid, 0.5 mol of allyl sulfonic acid, and 0.8 mol of p-toluene sulfonic acid with 2 L of deionized water to prepare an organic acid-containing aqueous solution. The organic acid is heated during the dissolution process, and the heating temperature is 60°C. Then, weigh 3 mol of vanadyl sulfate and add an aqueous solution containing organic acid as a diluent. After all of it is dissolved, pour it into a volumetric flask and dilute to 1000 mL to obtain a 3mol / L vanadyl sulfate solution. Ultrasonic treatment was carried out during the dissolution of vanadyl sulfate, and the treatment time was 30 minutes. Graphite is used as the anode and cathode materials, the concentration of the anode and cathode solutions are 3mol / L vanadyl sulfate and 1.8mol / L organic acid aqueous solution, and the charging current density is 30mA / cm 2 , The discharge current density is 30mA / cm 2 , The voltage efficiency is 83%, the Coulomb efficiency is 90%, and the en...

Embodiment 3

[0030] Weigh 3mol vanadyl sulfate, add 800mL deionized water, heat at 80℃, wait for all of them to dissolve, add: 0.5mol ethynylsulfonic acid, 0.5mol m-hydroxybenzenesulfonic acid, 1.5mol p-hydroxybenzenesulfonic acid, continue to stir After dissolving completely, add deionized water to make the volume to 1000mL to obtain a 3mol / L vanadyl sulfate solution. Ultrasonic treatment was performed during the dissolution of vanadyl sulfate, and the treatment time was 90 minutes. Graphite is used as the anode and cathode materials, the concentration of the anode and cathode solutions are both 3mol / L vanadyl sulfate and 2.5mol / L vanadyl sulfate solution, and the charging current density is 30mA / cm 2 , The discharge current density is 30mA / cm 2 , The voltage efficiency is 87%, the Coulomb efficiency is 93%, and the energy efficiency is 81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| voltage efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com