Preparation method of TiO2/graphene composite film

A composite film and graphene technology, applied in the field of nanomaterials and photocatalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 0.3 g graphite powder, 0.5 g K 2 S 2 o 4 and 0.5 g P 2 o 5 Mix and add to 2 ~ 4 ml of concentrated H with a mass fraction of 98% 2 SO 4 , stirred at constant temperature at 80°C for 4 hours to obtain a dark blue solution. After filtration, the initial product was added to 12 ml of concentrated H with a mass fraction of 98%. 2 SO 4 , slowly add 1.5 g KMnO 4 , so that the temperature of the mixed solution does not exceed 20 °C, and then stirred at a constant temperature of 35 °C for 2 hours, the solution turned yellowish brown. After adding 25 ml of distilled water, continue stirring, and after 2 hours, add 70 ml of distilled water and 2 ml of 30% H 2 o 2 , reducing the incompletely reacted KMnO 4 , the solution turned bright yellow. Filtration, pickling, water washing, and drying are performed in sequence to obtain graphene oxide.

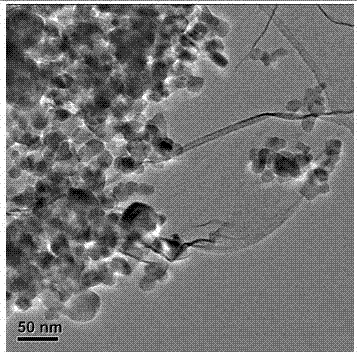

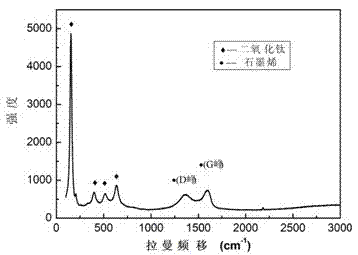

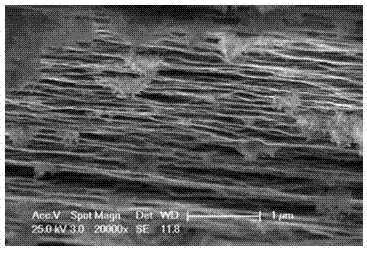

[0033] Configure graphene oxide and TiO separately 2 The ethanol suspension of nanoparticles has a mass concentration of 0.1 m...

Embodiment 2

[0035] Example 2 : mix 0.3 g graphite powder, 0.5 g K 2 S 2 o 4 and 0.5 g P 2 o 5 Mix and add to 2 ~ 4 ml concentrated H with a mass fraction of 98% 2 SO 4 , stirred at constant temperature at 80°C for 4 hours to obtain a dark blue solution. After filtration, the initial product was added to 12 ml of concentrated H with a mass fraction of 98%. 2 SO 4 , slowly add 1.5 g KMnO 4 , so that the temperature of the mixed solution does not exceed 20 °C, and then stirred at a constant temperature of 35 °C for 2 hours, the solution turned yellowish brown. After adding 25 ml of distilled water, continue stirring, and after 2 hours, add 70 ml of distilled water and 2 ml of 30% H 2 o 2 , reducing the incompletely reacted KMnO 4 , the solution turned bright yellow. Filtration, pickling, water washing, and drying are performed in sequence to obtain graphene oxide.

[0036] Configure graphene oxide and TiO separately 2 The acetone suspension of nanoparticles has a mass concent...

Embodiment 3

[0038] Example 3 : mix 0.3 g graphite powder, 0.5 g K 2 S 2 o 4 and 0.5 g P 2 o 5 Mix and add to 2 ~ 4 ml concentrated H with a mass fraction of 98% 2 SO 4 , stirred at constant temperature at 80°C for 4 hours to obtain a dark blue solution. After filtration, the initial product was added to 12 ml of concentrated H with a mass fraction of 98%. 2 SO 4 , slowly add 1.5 g KMnO 4 , so that the temperature of the mixed solution does not exceed 20 °C, and then stirred at a constant temperature of 35 °C for 2 hours, the solution turned yellowish brown. After adding 25 ml of distilled water, continue stirring, and after 2 hours, add 70 ml of distilled water and 2 ml of 30% H 2 o 2 , reducing the incompletely reacted KMnO 4 , the solution turned bright yellow. Filtration, pickling, water washing, and drying are performed in sequence to obtain graphene oxide.

[0039] Configure graphene oxide and TiO separately 2 The ethanol suspension of nanoparticles has a mass concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com