Epoxy resin composition with hydrated alumina

A technology of hydrated alumina and epoxy resin, used in electrical components, circuits, electrical solid devices, etc., can solve the problems of reducing moisture resistance, fluidity, reliability, etc., and achieve the effect of excellent solder resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

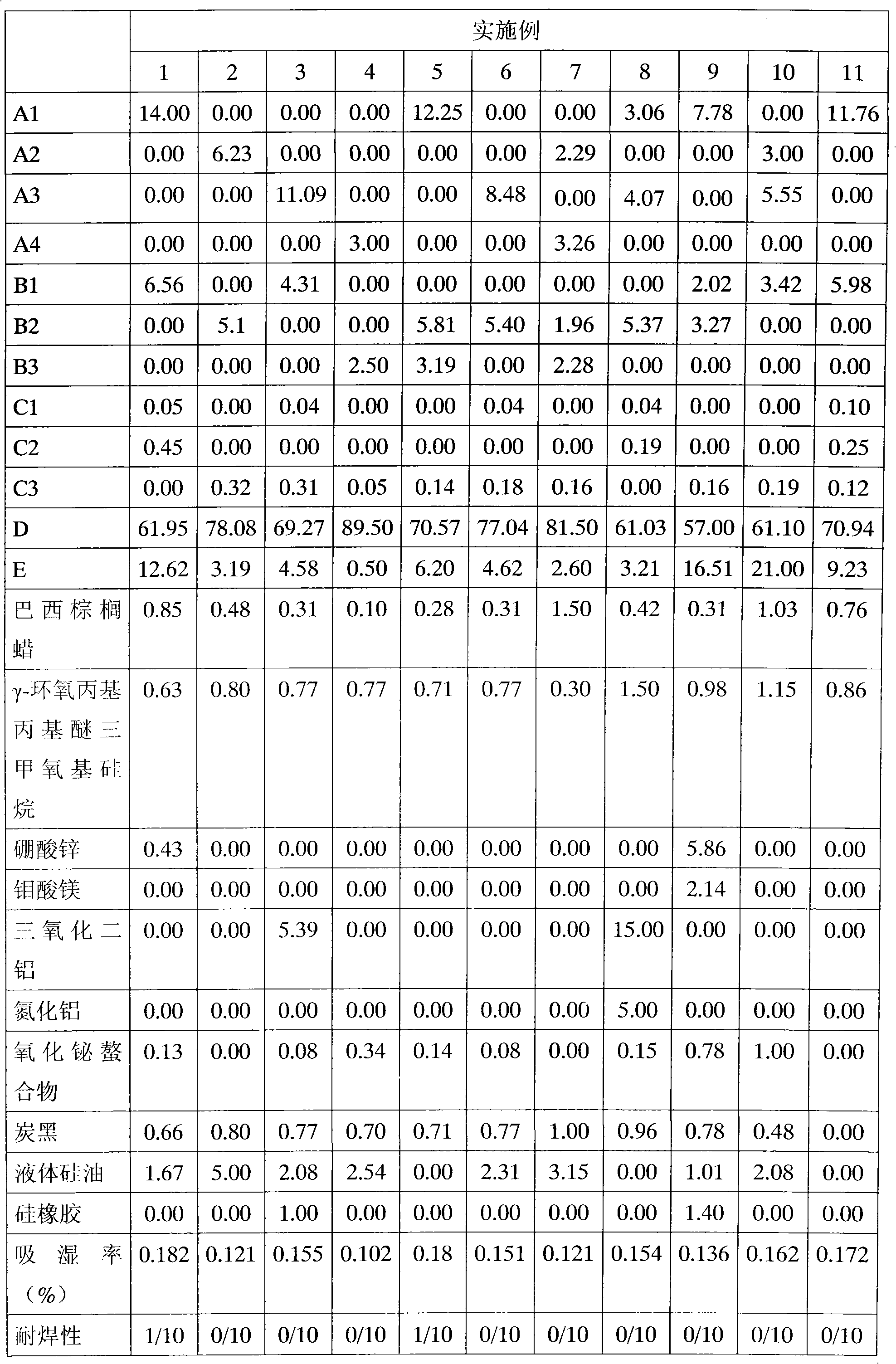

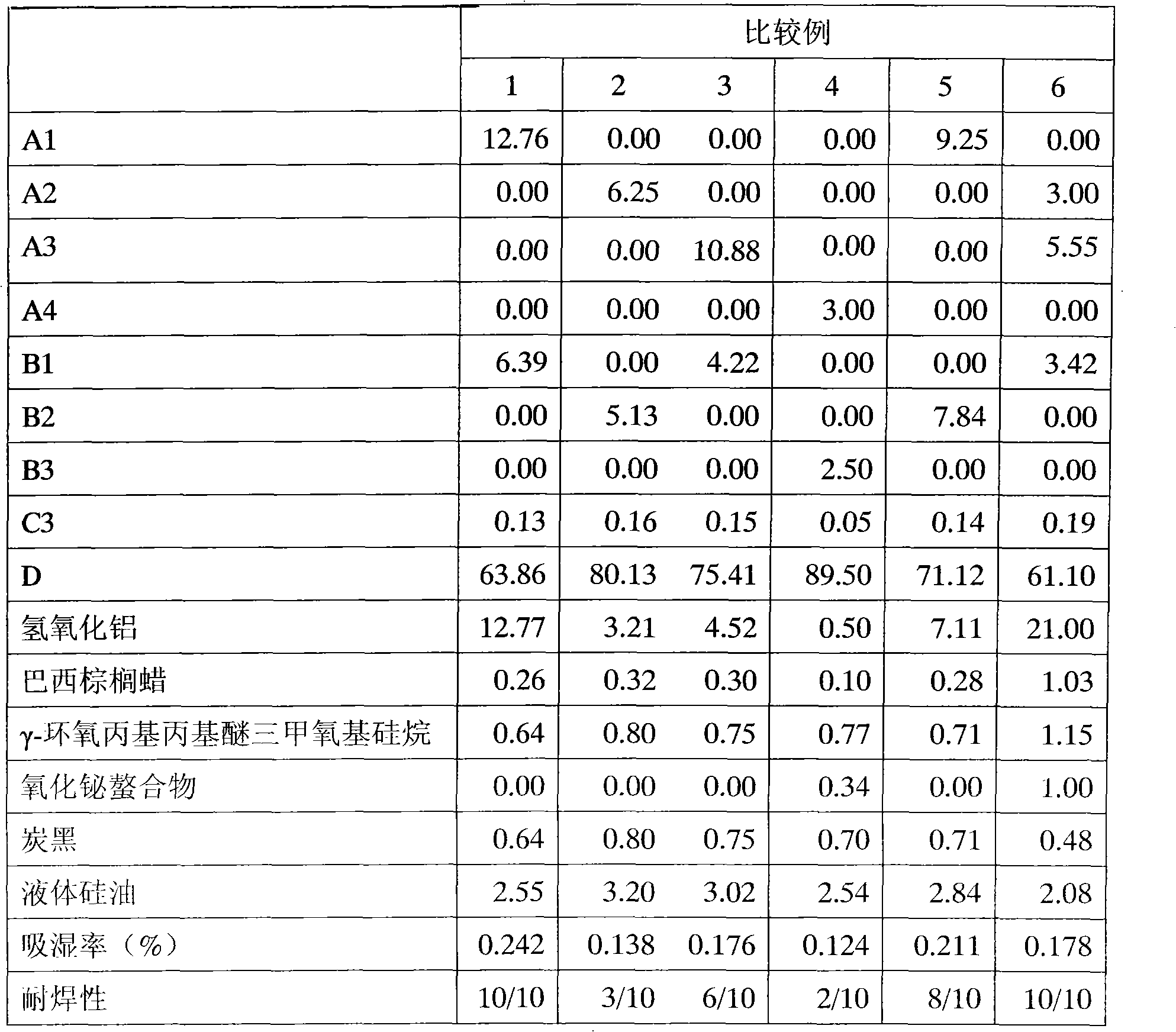

Examples

Embodiment 1

[0038] O-cresol novolac epoxy resin A1 ("N-660" manufactured by DIC Corporation of Japan) 14wt%

[0039] Phenol novolac resin B1 ("TD-2131" manufactured by DIC Corporation of Japan) 6.56wt%

[0040] 2-Methylimidazole C1 0.05wt%

[0041] 1,8-diazabicyclo(5,4,0)undecene-7C2 0.45wt%

[0042] Silica powder D (d50 is 25um) 61.95wt%

[0043] Alumina monohydrate E (d50 is 2um) 12.62wt%

[0044] Carnauba wax 0.85wt%

[0045] γ-Glycidylpropyl ether trimethoxysilane 0.63wt%

[0046] Zinc borate (d50 is 1um) 0.43wt%

[0047] Bismuth oxide chelate 0.13wt%

[0048] Carbon black 0.66wt%

[0049] Liquid silicone oil 1.67wt%

[0050] After weighing and mixing according to the above ratio, melt and knead evenly on a double-roller mixer preheated at a temperature of 70-100°C, remove the uniformly mixed material from the double-roller mixer, cool naturally, and pulverize The powdery material was obtained, preformed into a cake, and the epoxy resin composition molding material was obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com