All-band reverse optical detector constructed on basis of organic small molecular material

An optical detector, full-band technology, applied in photovoltaic power generation, electric solid state devices, semiconductor devices and other directions, can solve the problems of high cost, high operating voltage, complex material manufacturing process, etc., to achieve low cost, easy device structure, spectral Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

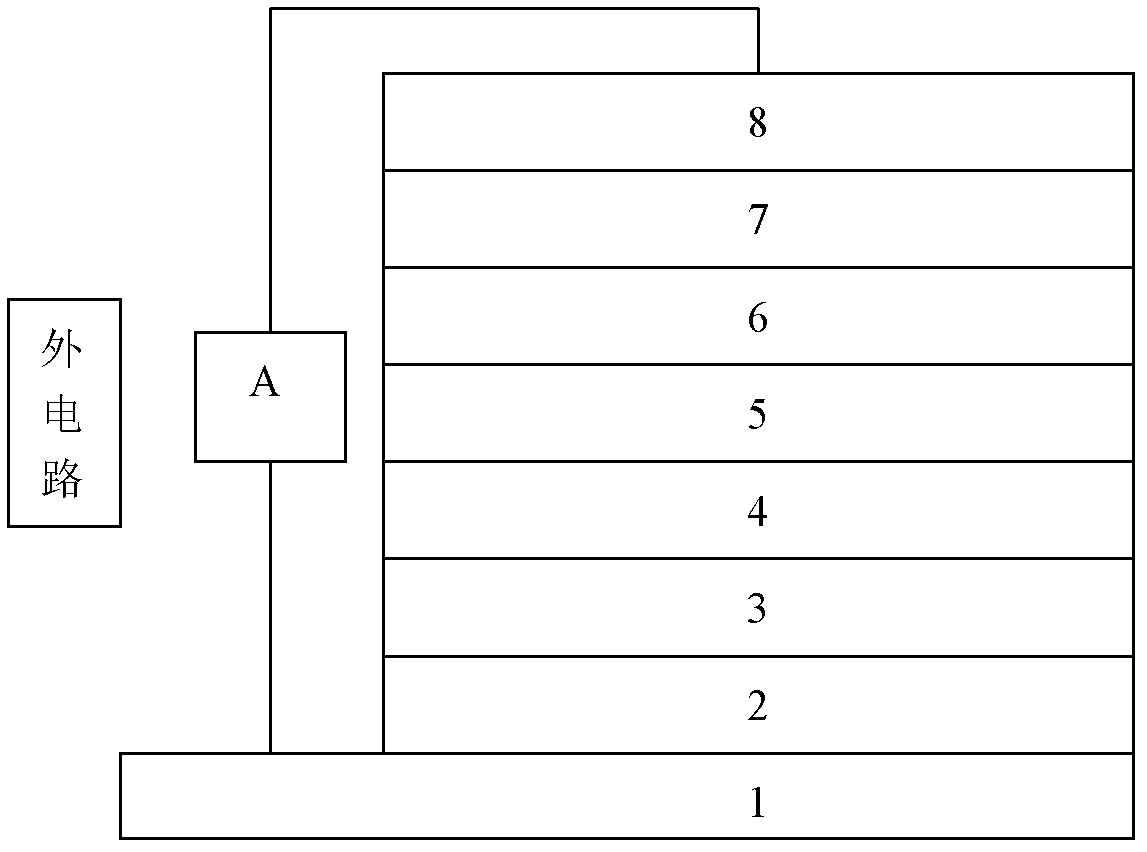

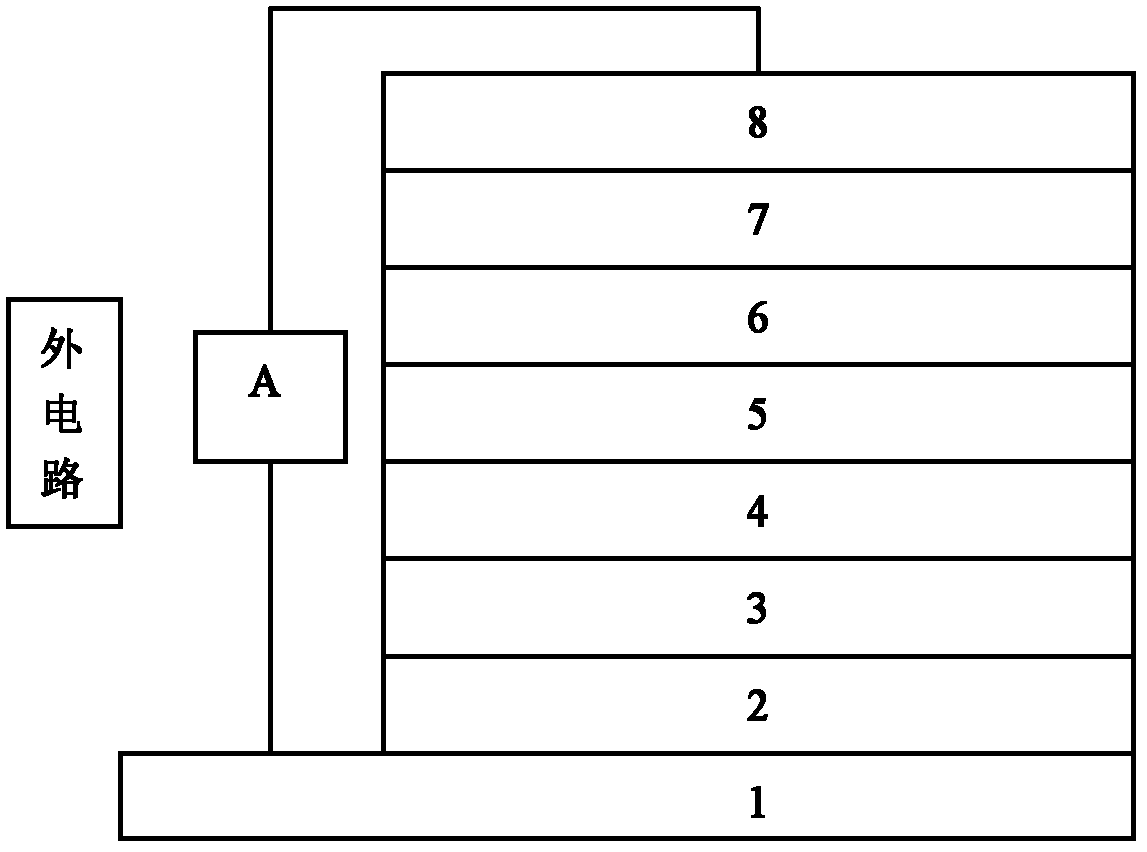

[0027] The preparation method of the present invention: deposit the first electron donor layer on the hole collecting electrode layer; deposit the first electron acceptor layer on the electron donor layer; The bulk layer; then the exciton blocking layer is prepared by dual-source co-deposition method; finally, the first electron collecting electrode layer and the second electron collecting electrode layer are deposited; the above-mentioned layers all adopt vacuum thermal deposition process.

[0028] The substrate is made of glass, and the hole-collecting electrode layer (transparent conductive film) is made of indium tin oxide ITO transparent conductive film; the first electron donor layer is made of m-MTDATA or 2-TNATA, or a mixture thereof, and the mixing mass ratio is 9:1, the thickness is selected from 1 to 20nm; the first electron acceptor layer (and the second electron donor layer) is selected from CuPc or TiOPC, and the thickness is selected from 2 to 40nm; the second el...

Embodiment 1

[0031] select figure 1 The device structure shown: In this embodiment, firstly, the hole-collecting electrode layer 2 selects the indium tin oxide ITO film on the glass substrate 1 as the transparent conductive film. After cleaning the transparent conductive film on the substrate 1, at first in high vacuum (3~2×10 -4 Pa), on the transparent conductive film 2, deposit a layer of thickness and be the first electron donor layer 3 of 10nm, the material of the first electron donor layer 3 adopts m-MTDATA; Then deposit 30nm on the first electron donor layer 3 The first electron acceptor layer 4, the material of the first electron acceptor layer 4 adopts TiOPc; The second electron acceptor layer 5 of 10nm is deposited on the first electron acceptor layer 4, the material of the second electron acceptor layer 5 Use F 16 A mixture layer of CuPc and PTCDI-C8, the mixing mass ratio of the two is 1:1; a 10nm exciton blocking layer 6 is deposited on the second electron acceptor layer 5, a...

Embodiment 2

[0033] select figure 1 The device structure shown: the hole collection electrode layer 2 selects the indium tin oxide ITO film on the glass substrate 1 as the transparent conductive film; the material of the first electron donor layer 3 is 2-TNATA, and the thickness is 15nm; The first electron acceptor layer 4 of 30nm is deposited on the electron donor layer 3, the material of the first electron acceptor layer 4 adopts TiOPc; Then the second electron acceptor layer 5 of 5nm is deposited on the first electron acceptor layer 4 , the material of the second electron acceptor layer 5 adopts F 16 A mixture layer of CuPc and PTCDI-C8, the mixing mass ratio of the two is 1:1; a 5nm exciton blocking layer 6 is deposited on the second electron acceptor layer 5, and the material of the exciton blocking layer 6 adopts a mass fraction of 3% Ce 2 CO 3 Doped Bphen; on the exciton blocking layer 6, deposit the first electron collecting electrode layer 7 of 10nm, the material of the first el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com