Tungsten carbide composite material containing aluminum oxide particles and silicon nitride whiskers, and preparation method thereof

A technology of tungsten carbide composite materials and silicon nitride whiskers, which is applied in the field of tungsten carbide materials and its preparation, can solve the problems of low fracture toughness, hindering the application of materials, and waiting for further development and research, and achieve high hardness, oxidation resistance and resistance Effects of improved corrosion performance and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

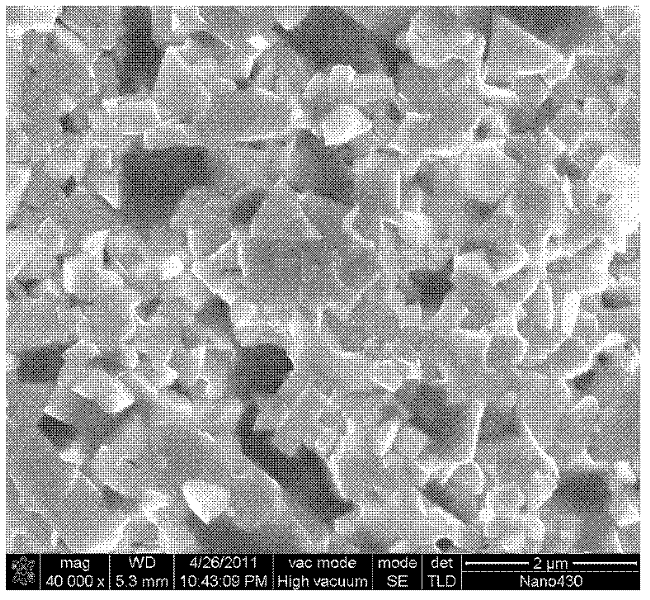

Embodiment 1

[0078] The preparation method of the tungsten carbide composite material containing aluminum oxide particles and silicon nitride whiskers comprises the following steps and process conditions:

[0079] Step 1: Prepare materials

[0080] Will WC, Al 2 o 3 , a-Si 3 N 4 The powder is proportioned according to the following mass percentages: WC 96%, Al 2 o 3 1%, a-Si 3 N 4 3%, the rest are unavoidable trace impurities; WC powder purity ≥ 98.7%, particle size about 100nm, Al 2 o 3 Powder purity ≥ 99.9%, particle size 1 ~ 2μm, a-Si 3 N 4 The oxygen content on the surface of the powder is 3-5wt.%, and the particle size is 0.8-1 μm.

[0081] Step 2: Powder dispersion and mixing

[0082] Submerge the above-mentioned raw material powder in ethanol, perform ultrasonic vibration and mechanical stirring to disperse the agglomerated powder, and then perform wet low-energy ball milling on the obtained slurry. The ball mill used is planetary, and the ball mill (500mL) and the ball ...

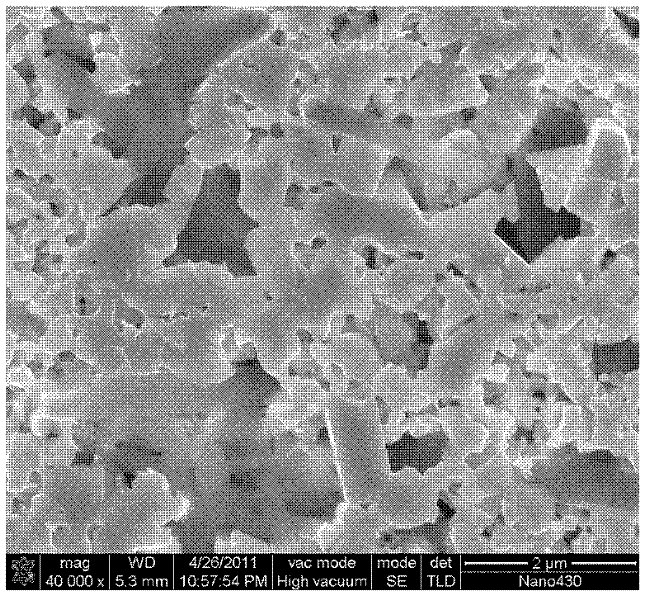

Embodiment 2

[0089] The preparation method of the tungsten carbide composite material containing aluminum oxide particles and silicon nitride whiskers comprises the following steps and process conditions:

[0090] Step 1: Prepare materials

[0091] Will WC, Al 2 o 3 , a-Si 3 N 4 The powder is proportioned according to the following mass percentages: WC 94%, Al 2 o 3 1%, a-Si 3 N 4 5%, the rest are unavoidable trace impurities; WC powder purity ≥ 98.7%, particle size about 100nm, Al 2 o 3 Powder purity ≥ 99.9%, particle size 1 ~ 2μm, a-Si 3 N 4 The oxygen content on the surface of the powder is 3-5wt.%, and the particle size is 0.8-1 μm.

[0092] Step 2: Powder dispersion and mixing

[0093] Submerge the above-mentioned raw material powder in ethanol, perform ultrasonic vibration and mechanical stirring to disperse the agglomerated powder, and then perform wet low-energy ball milling on the obtained slurry. The ball mill used is planetary, and the ball mill (500mL) and the ball ...

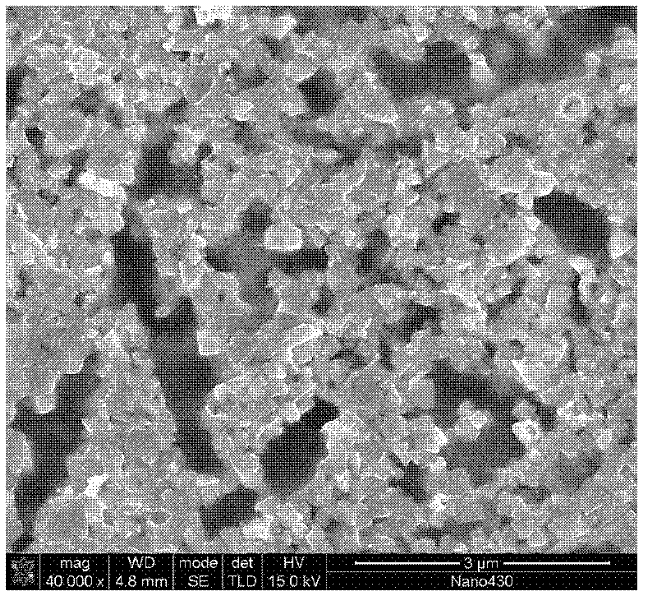

Embodiment 3

[0100] The preparation method of the tungsten carbide composite material containing aluminum oxide particles and silicon nitride whiskers comprises the following steps and process conditions:

[0101] Step 1: Prepare materials

[0102] Will WC, Al 2 o 3 , a-Si 3 N 4 The powder is proportioned according to the following mass percentages: WC 97%, Al 2 o 3 1%, a-Si 3 N 4 2%, the rest are unavoidable trace impurities; WC powder purity ≥ 98.7%, particle size about 100nm, Al 2 o 3 Powder purity ≥ 99.9%, particle size 1 ~ 2μm, a-Si 3 N 4 The oxygen content on the surface of the powder is 3-5wt.%, and the particle size is 0.8-1 μm.

[0103] Step 2: Powder dispersion and mixing

[0104] Submerge the above-mentioned raw material powder in ethanol, perform ultrasonic vibration and mechanical stirring to disperse the agglomerated powder, and then perform wet low-energy ball milling on the obtained slurry. The ball mill used is planetary, and the ball mill (500mL) and the ball ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com