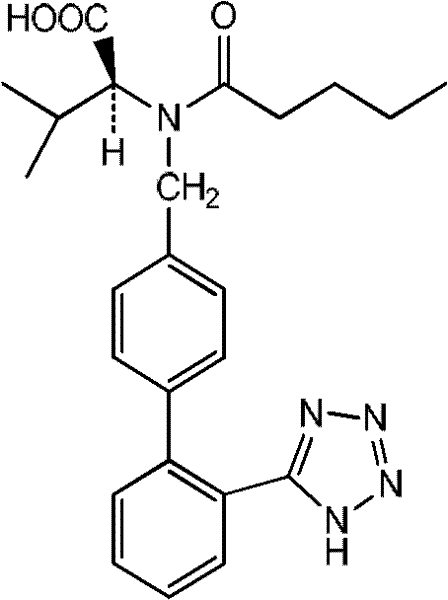

Preparation method of high purity valsartan

A valsartan, high-purity technology, applied in the field of preparation of high-purity valsartan, can solve the problems of undetected impurities, undetected, undetected chiral isomers, etc., to achieve environmental protection and simple operation , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 Preparation of valsartan crude product

[0030] Add 200g of valsartan methyl ester to a 3000ml three-necked flask, then add 790g of 10% potassium hydroxide aqueous solution, stir and react at 30°C for 8 hours, after the reaction is complete, cool down to below 15°C, dropwise add mass Concentrated hydrochloric acid with a percentage concentration of 36% was used to adjust the pH value to 1. After the adjustment, 1000 ml of ethyl acetate was added to extract and separate layers. The ethyl acetate layer was washed with an aqueous solution of sodium bicarbonate with a concentration of 5% by mass until weakly acidic. (pH value is 6.9), washed once with saturated brine, dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated to obtain crude valsartan.

Embodiment 2

[0031] Embodiment 2 Preparation of crude product of valsartan

[0032] Add 200g of valsartan methyl ester to a 3000ml three-necked flask, then add 790g of 10% potassium hydroxide aqueous solution, stir and react at 30°C for 8 hours, after the reaction is complete, cool down to below 15°C, dropwise add mass Concentrated hydrochloric acid with a percentage concentration of 32% was used to adjust the pH value to 1.5. After the adjustment, 1000ml of ethyl acetate was added to extract and separate layers, and the ethyl acetate layer was washed with an aqueous sodium bicarbonate solution with a concentration of 5% by mass until weakly acidic. (pH value is 6.5), washed once with saturated brine, dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated to obtain crude valsartan.

Embodiment 3

[0033] Example 3 The heavy refining of valsartan

[0034] Add 500ml of ethyl acetate to the crude valsartan obtained in Example 1, dissolve at 50°C, after dissolving, cool to 0°C to crystallize for 10 hours, centrifuge to obtain valsartan, yield 95%, valsartan Quality: related impurities 0.6%, chiral isomer 0.5%.

[0035] Add 100g of the above-prepared valsartan to a 1000ml three-neck flask, then add 600ml of ethyl acetate to dissolve at 50°C, after dissolving, cool down to 0°C to crystallize for 20 hours, centrifuge, and dry to obtain fine valsartan with a yield of 90% %, mass: related impurities were not detected, chiral isomers were not detected, and the residual ethyl acetate was 14000ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com