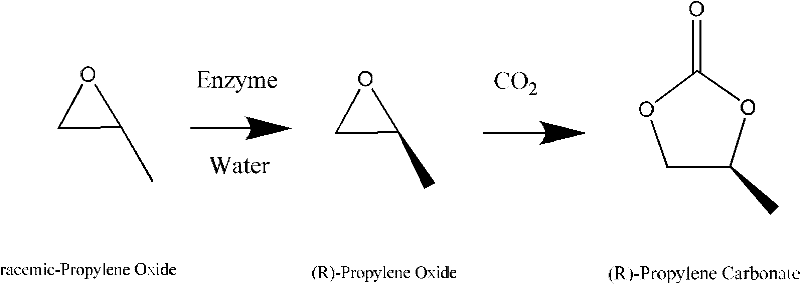

Preparation method of (R)-propene carbonate

A technology of propylene carbonate and propylene oxide, applied in the field of preparation of Novovir intermediates, can solve the problems of high production risk and high equipment requirements, and achieve the effects of low risk, less equipment investment and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Put 116 grams of (R)-propylene oxide and 1 gram of epoxyhydrolase ECU1040 into the reaction bottle, cool to 5°C in an ice-water bath, and add 50 grams of water dropwise. Control the temperature not to exceed 5°C. After dropping, the ice-water bath was removed, and the temperature was naturally raised to room temperature. The reaction was continued for 24 hours, and the reaction was stopped. Atmospheric pressure distilled (R)-propylene oxide 53 g, chemical purity 99.68%, optical purity 99.55% e.e. Yield 91.38%.

[0021] (2) Put 50g of (R)-propylene oxide and 200ml of ethanol obtained above into a 500mL reaction bottle, cool to 16°C, add 0.6g of cinchona base and 1.8g of triethylamine successively, stir for 15 minutes and then pass in carbon dioxide gas , keep the temperature not higher than 20°C. After 20 hours of reaction, carbon dioxide gas was no longer absorbed. The ethanol solvent was recovered by heating and atmospheric distillation, and 85.62 grams of pro...

Embodiment 2

[0023] (1) Put 116 grams of (R)-propylene oxide and 2.3 grams of epoxyhydrolase ECU1040 into the reaction bottle, cool to 0° C. in an ice-water bath, and add 22 grams of water dropwise. Control the temperature not to exceed 5°C. After dropping, the ice-water bath was removed, and the temperature was naturally raised to room temperature. The reaction was continued for 24 hours, and the reaction was stopped. Atmospheric pressure distilled 58 g of (R)-propylene oxide with a chemical purity of 99.73% and an optical purity of 99.65% e.e. Yield 92.38%.

[0024] (2) Put 50g of (R)-propylene oxide and 180ml of methanol obtained above into a 500mL reaction bottle, cool to 12°C, add 1.0g of cinchona base and 2.5g of ethylenediamine successively, stir for 15 minutes and then introduce carbon dioxide Gas, keep the temperature not higher than 20°C. After 24 hours of reaction, carbon dioxide gas was no longer absorbed. The methanol solvent was recovered under normal pressure by heating...

Embodiment 3

[0026] (1) Put 116 grams of (R)-propylene oxide and 1.1 grams of epoxyhydrolase ECU1040 into the reaction bottle, cool in an ice-water bath to 0-5°C, and add 232 grams of water dropwise. Control the temperature not to exceed 5°C. After dropping, the ice-water bath was removed, and the temperature was naturally raised to room temperature. The reaction was continued for 24 hours, and the reaction was stopped. 55 g of (R)-propylene oxide was distilled out under atmospheric pressure, with a chemical purity of 99.68% and an optical purity of 99.57% e.e. The yield is 91.68%.

[0027] (2) Put 50g of (R)-propylene oxide and 200ml of tert-butanol obtained above into a 500mL reaction flask, cool to 13°C, add 1.2g of cinchona base and 3.6g of diethylamine successively, stir for 15 minutes and pass Inject carbon dioxide gas and keep the temperature not higher than 20°C. React for 15 hours until carbon dioxide gas is no longer absorbed. The tert-butanol solvent was recovered by heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chiral purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com