Synthesis of novel flame-retarding polyester polyol, and application thereof in polyurethane

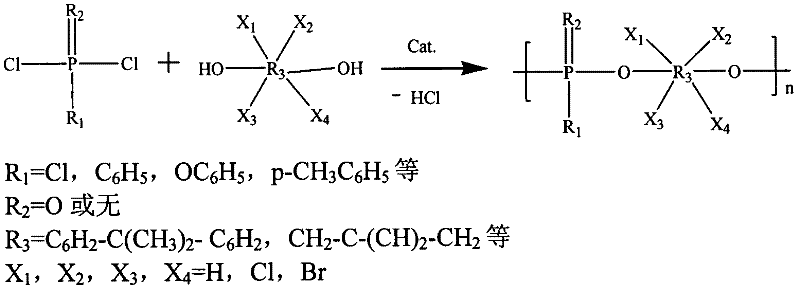

A flame-retardant polyester and polyol technology, which is applied in the field of preparation of new flame-retardant polyester polyols for polyurethane, can solve the problems of bromine content to be further improved, flame-retardant performance limited, etc. The effect of mild conditions and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

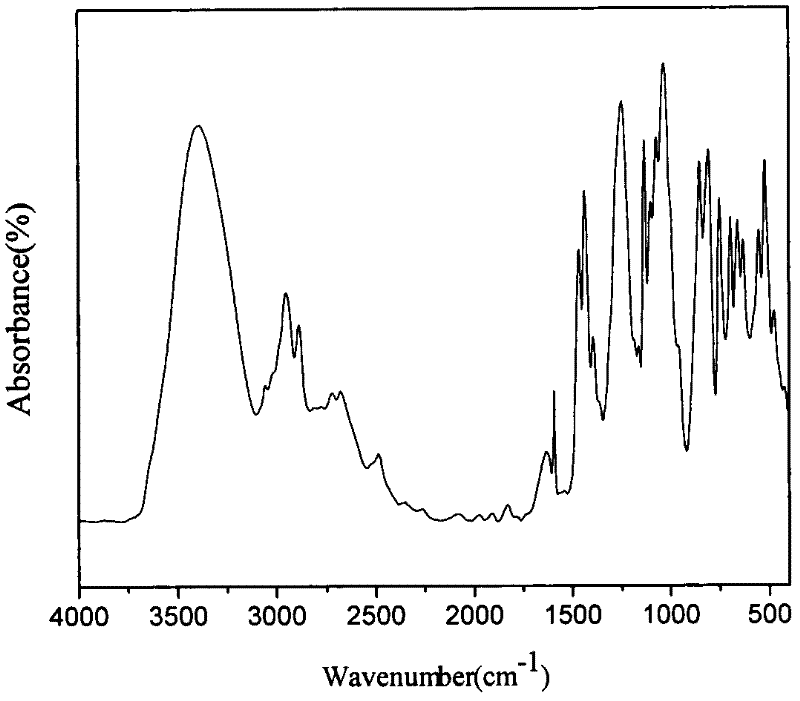

[0024] Add 87.30g of dibromoneopentyl glycol, 33.73g of triethylamine and 30g of N-methylpyrrolidone to the four-necked flask, and gradually raise the temperature to 80°C. 2 Add 32.50 g of phenylphosphoryl dichloride and 60 g of toluene dropwise under the atmosphere, and control the dropwise addition in about 2 hours. After the dropwise addition, continue the reaction at 80°C for 2h under the condition of condensation and reflux, and then raise the temperature to 100°C for 4h to obtain viscous THICK BROWN LIQUID. The resulting liquid was filtered under reduced pressure to remove triethylamine hydrochloride to obtain a clear liquid. The filtrate was successively washed with 0.1 mol / L hydrochloric acid solution, saturated sodium carbonate solution and deionized water, then the toluene was removed under reduced pressure, and finally the product was obtained by drying in a vacuum oven. The hydroxyl value of the product was determined to be 145 mgKOH / g, and the acid value was 1.8 ...

Embodiment 2

[0027] Add 87.31 g of dibromoneopentyl glycol, 38.00 g of potassium carbonate and 60 g of xylene in the four-necked flask, and gradually heat up to 80 ° C. 2 Add 52.80g of phenylphosphoryl dichloride and 100g of xylene dropwise under the atmosphere, and control the dropwise addition in about 2 hours. After the dropwise addition, continue to react at 80°C for 2h under condensing and reflux conditions, and then raise the temperature to 100°C for 4h to obtain Viscous brown liquid. The resulting liquid was filtered under reduced pressure to remove solid matter to obtain a clear liquid. The filtrate was successively passed through 0.1 mol / L hydrochloric acid solution, saturated sodium carbonate solution, and deionized water to wash, then remove the solvent on a rotary evaporator, and finally dry in a vacuum oven to obtain the product. The hydroxyl value of the product was determined to be 54 mgKOH / g.

[0028] Take 50g of the above-mentioned flame-retardant polyester, 50g of polye...

example 3

[0030] Add 181.30g of tetrabromobisphenol A, 33.73g of triethylamine and 160g of N-methylpyrrolidone (NMP) to the four-necked flask, and gradually raise the temperature to 80°C. 2 Under the atmosphere, 29.83g of phenyl phosphorus dichloride and 60g of NMP were added dropwise. After the dropwise addition, the reaction was continued at 80°C for 4h, and then the temperature was raised to 100°C for 10h to obtain a viscous brown liquid. The resulting liquid was filtered to remove triethylamine hydrochloride to obtain a clear liquid. The filtrate was sequentially washed with 0.1 mol / L hydrochloric acid, saturated sodium carbonate solution and deionized water, then the solvent was removed on a rotary evaporator, and finally dried in a vacuum oven to obtain the product. The hydroxyl value of the product was determined to be 94 mgKOH / g.

[0031] Take 30g of the above-mentioned polyester and 70g of polyether polyol NJ220 into a three-necked flask. After vacuum dehydration at 90°C for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com