Pre-modified PVC (Polyvinyl Chloride) resin and modified PVC (Polyvinyl Chloride) resin as well as preparation method thereof and application thereof

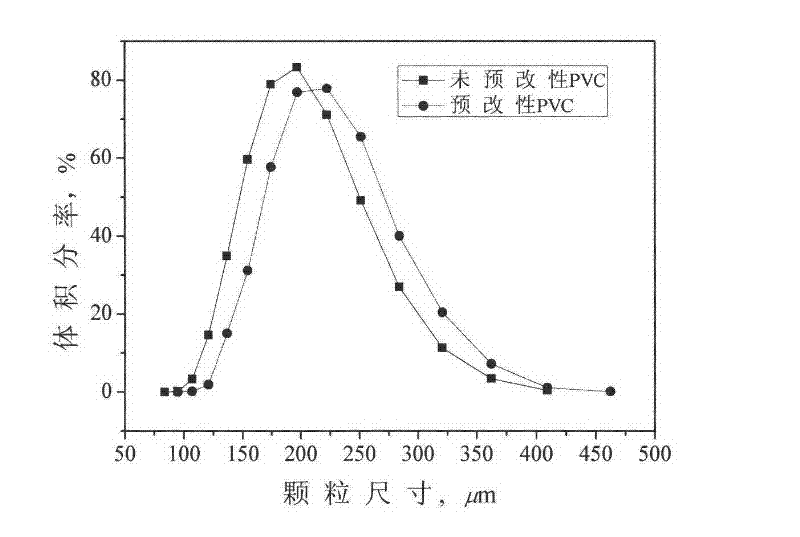

A PVC resin and modification technology, applied in the polymer field, can solve the problems of poor mixing of PVC powder and modified materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0055] Record in embodiment 4: 2.65kg of n-butane, 0.015kg of n-butanone, 0.02kg of n-butanol and 0.015kg of HFC-125. Therefore, n-butane accounts for 98.15% of the total amount of structural modifiers, n-butanone accounts for 0.555%, n-butanol accounts for 0.74%, and HFC-125 accounts for 0.555%.

[0056] Table 1 One or more structural modifiers participate in the implementation table of PVC powder structure modification

[0057]

[0058]

[0059]

[0060] Explanation: In Table 1, the state of each compound at normal temperature and pressure is expressed as: "L" is liquid, "G" is gas, and "S" is solid.

[0061] Table 2

[0062]

[0063]

[0064] Table 3 Structure Modifier Content Component Table

[0065]

[0066]

Embodiment 1

[0068] Put 1.35kg of PVC resin powder into the reaction kettle, add 25.65g of the required auxiliary agent tetradecyl hydroxypropyl phosphate betaine according to the first group formula in Table 1, seal the reaction kettle, stir and raise the temperature to 60°C Finally, 1.013kg of methane was introduced, and the modification was continued for 17 hours under this stable condition. After the modification, the valve was opened to discharge and evaporate within about 30 seconds, and then the pre-modified PVC resin powder was taken out from the kettle.

Embodiment 2

[0070] Put 1.35kg of PVC resin powder into the reaction kettle, add 54g of the required auxiliary agent tetrapropylammonium bromide according to the second group formula in Table 1, seal the reaction kettle, stir and raise the temperature to 45°C and keep the temperature constant, then pass in 2.05kg of ethane and 0.11kg of n-pentanone, and continue to modify under this stable condition for 15 hours. After the modification, open the valve to discharge and volatilize in about 60s, and then open the kettle to take out the pre-modified PVC resin powder .

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com