Magnetic immobilized cross-linking cellulase aggregates (CLEAs), preparation method and application thereof

A technology of cellulase and aggregates, applied in the direction of immobilization on or in the inorganic carrier, on or in the organic carrier, etc., can solve the problems that the enzyme immobilization technology has not been reported, and improve the operating performance Poor, Vitality-enhancing, Ease of Handling Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of Magnetic Chitosan Microspheres

[0052] Take by weighing 1.2g chitosan and dissolve in 40mL volume concentration and be 3% acetic acid solution, be mixed with the chitosan acidic colloid solution that mass volume ratio is 3%, add 0.3g Fe 3 o 4 Nanoparticles, 30KHz ultrasonic dispersion for 30min to form a uniformly dispersed magnetic chitosan colloidal solution. Under slow stirring, the above-mentioned magnetic chitosan solution was added to the oil phase system (composed of 160mL liquid paraffin, 4.2g Span 80 and 2.1g Tween 80), stirred at a speed of 1000r / min for 30min, then dropped into the volume Concentration of 3% glutaraldehyde solution, the final volume concentration of glutaraldehyde is 0.2%, continue to stir at 1000r / min for 1h at 40°C, and then adjust the pH value to 11 with 3mol / L NaOH. Then continue to react at 80° C. for 2 h, and finally collect magnetic chitosan composite microspheres under magnet adsorption, wash with acetone, petroleum ...

Embodiment 2

[0054] Preparation of Magnetic Chitosan Microspheres

[0055] Take by weighing 0.8g chitosan and dissolve in 40mL volume concentration and be 2% acetic acid solution, be mixed with the chitosan acidic colloid solution that mass volume ratio is 3%, add 0.8g Fe 3 o 4 Nanoparticles, 30KHz ultrasonic dispersion for 30min to form a uniformly dispersed magnetic chitosan colloidal solution. Under slow stirring, the above-mentioned magnetic chitosan solution was added to the oil phase system (composed of 160mL liquid paraffin, 5g Span 80 and 2.5g Tween 80), stirred at a speed of 1000r / min for 30min, and the volume concentration 3% glutaraldehyde solution, the final volume concentration of glutaraldehyde is 0.2%, and the reaction is continued at 40° C. with stirring at 1000 r / min for 1 h, and then the pH value is adjusted to 11 with 3 mol / L NaOH. Then continue to react at 60° C. for 2 h, and finally collect magnetic chitosan composite microspheres under magnet adsorption, wash with a...

Embodiment 3

[0057] (1) Precipitation of cellulase aggregates

[0058] 0.45g of magnetic chitosan composite microspheres prepared in Example 1 were added to 10mL of phosphate buffer (pH7.5, 0.05mol / L) and soaked for 12h to fully swell the microspheres, and then added to 5mL with a concentration of 3mg / L after centrifugation. In mL cellulase solution (prepared with pH 7.5, 0.05mol / L phosphate buffer), add 5 mL of ammonium sulfate solution with a saturation of 60% at 25°C for 3 hours, and then add 5 mL of ammonium sulfate solution at 10°C for 2 hours. The free cellulase that is not adsorbed by the magnetic chitosan microspheres will form cellulase aggregates and precipitate on the surface of the magnetic chitosan composite microspheres.

[0059] (2) Preparation of immobilized cross-linked cellulase aggregates

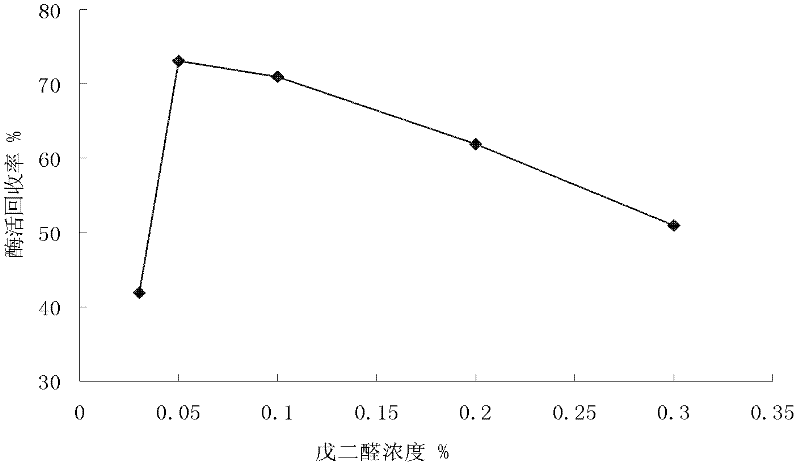

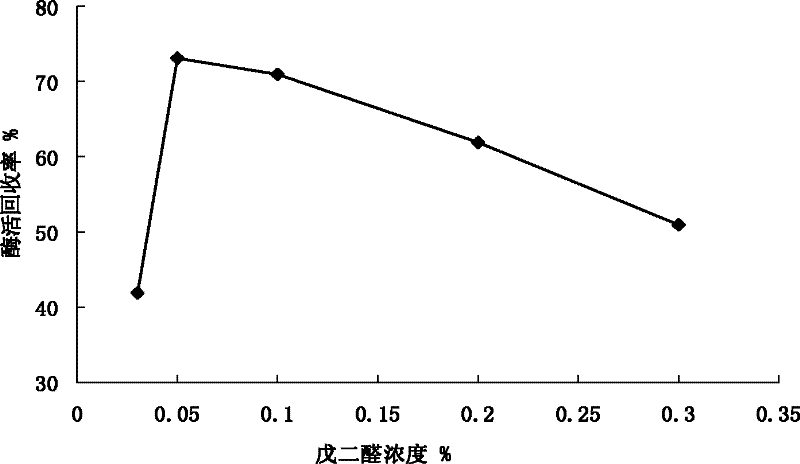

[0060] Add a volume concentration of 3% glutaraldehyde solution to the precipitated enzyme solution, the final concentration of glutaraldehyde in the solution is 0.1%, and carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com