On-line monitoring control method of electric car power cell high voltage loop resistor and apparatus thereof

A power battery and high-voltage circuit technology, which is applied in the direction of measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve the problems of not including shunt pressure difference, inaccurate voltage value, and increasing manufacturing costs, so as to achieve saving The effect of internal space, high accuracy, and precise data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

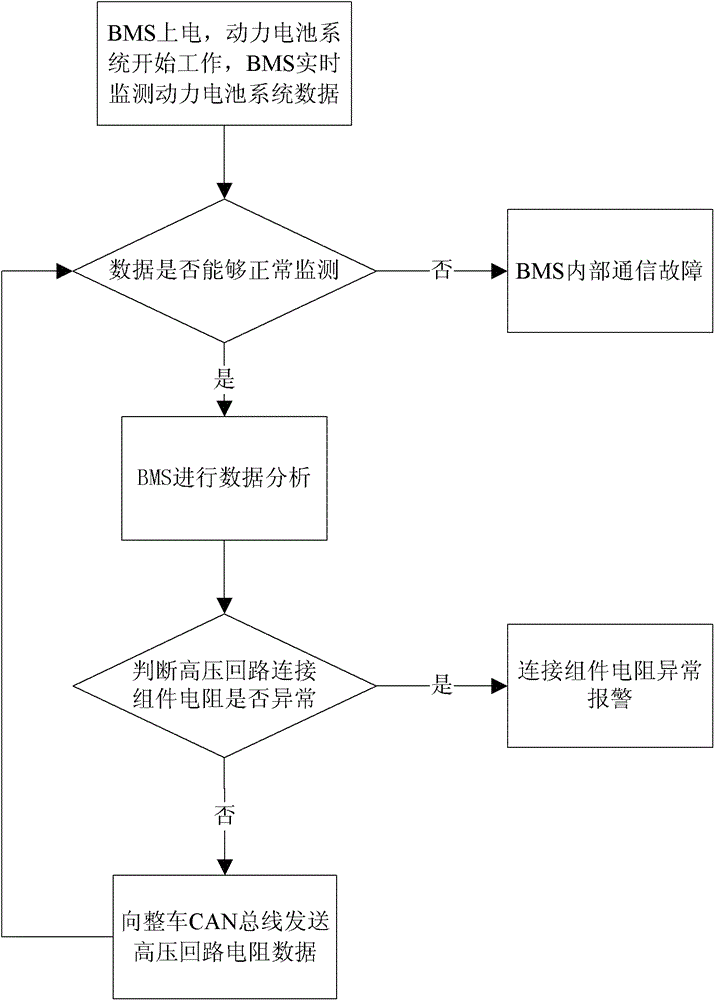

[0026]The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

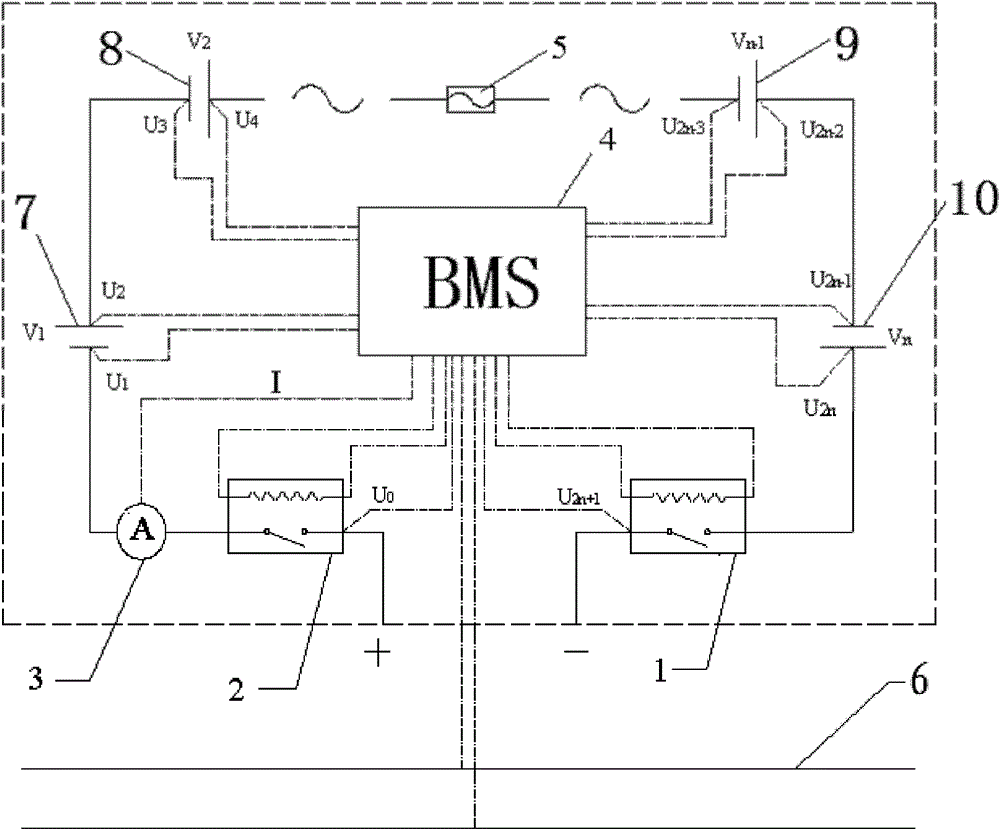

[0027] like figure 1 as shown,

[0028] The on-line monitoring and control device for electric vehicle power battery high-voltage circuit resistance includes shunt 3, main positive contactor 2, main negative contactor 1, fuse 5, CAN bus 6 and battery management system BMS4. The total negative relay 1, the total positive relay 2, the shunt 3, and the fuse 5 are all connected in series on the high-voltage circuit of the power battery, and each cell adopts double wiring for voltage detection, V 1 Indicates the voltage across the cell 7; V 2 Indicates the voltage across the cell 8; V n-1 Indicates the voltage at both ends of the cell 9; V n Indicates the voltage across the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com