Polyvinylidene fluoride resin composition, white resin film, and backsheet for solar cell module

一种树脂组合物、二氟乙烯的技术,应用在电路、光伏发电、电气元件等方向,能够解决耐久性差、白色树脂膜困难、耐热性、外观降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

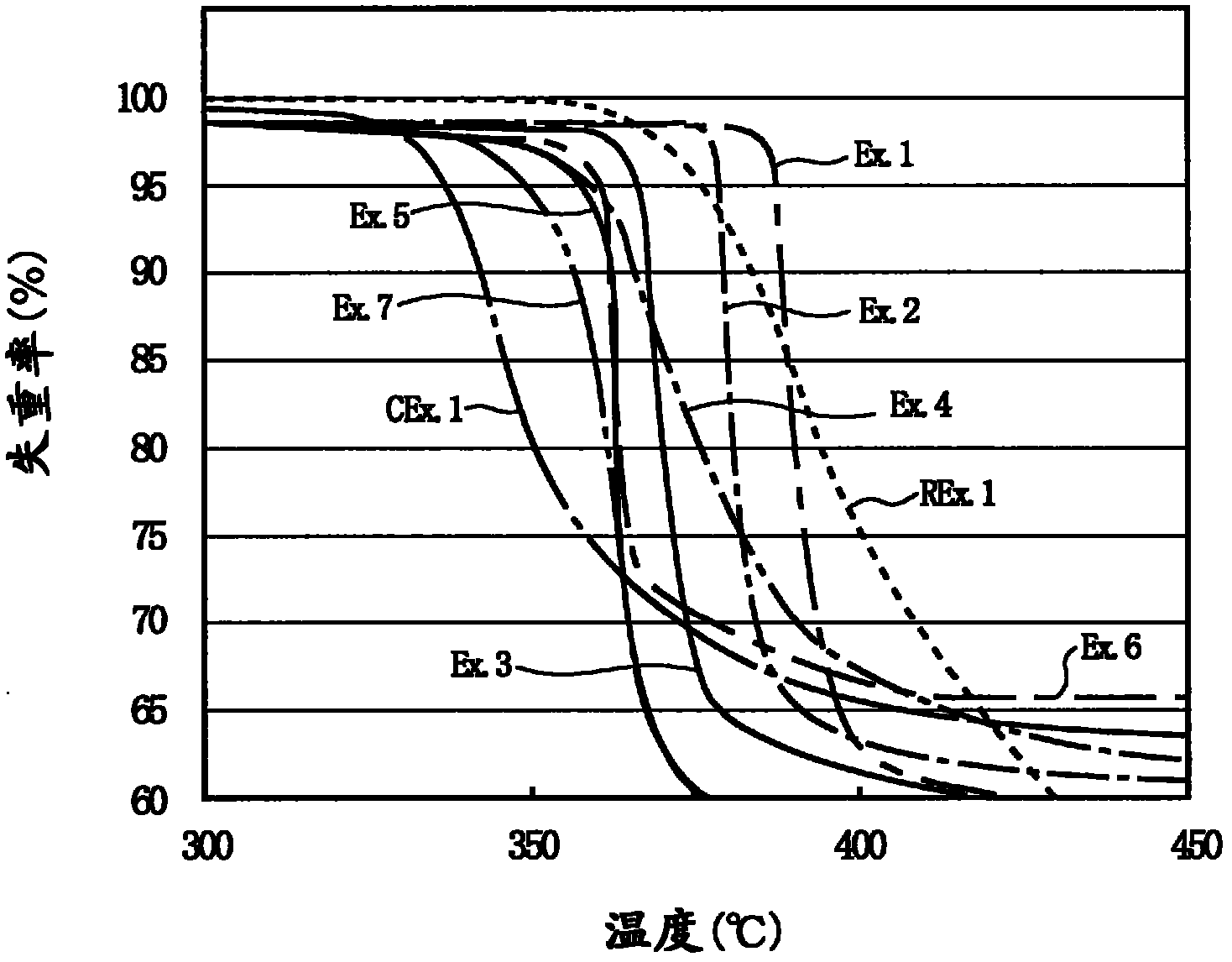

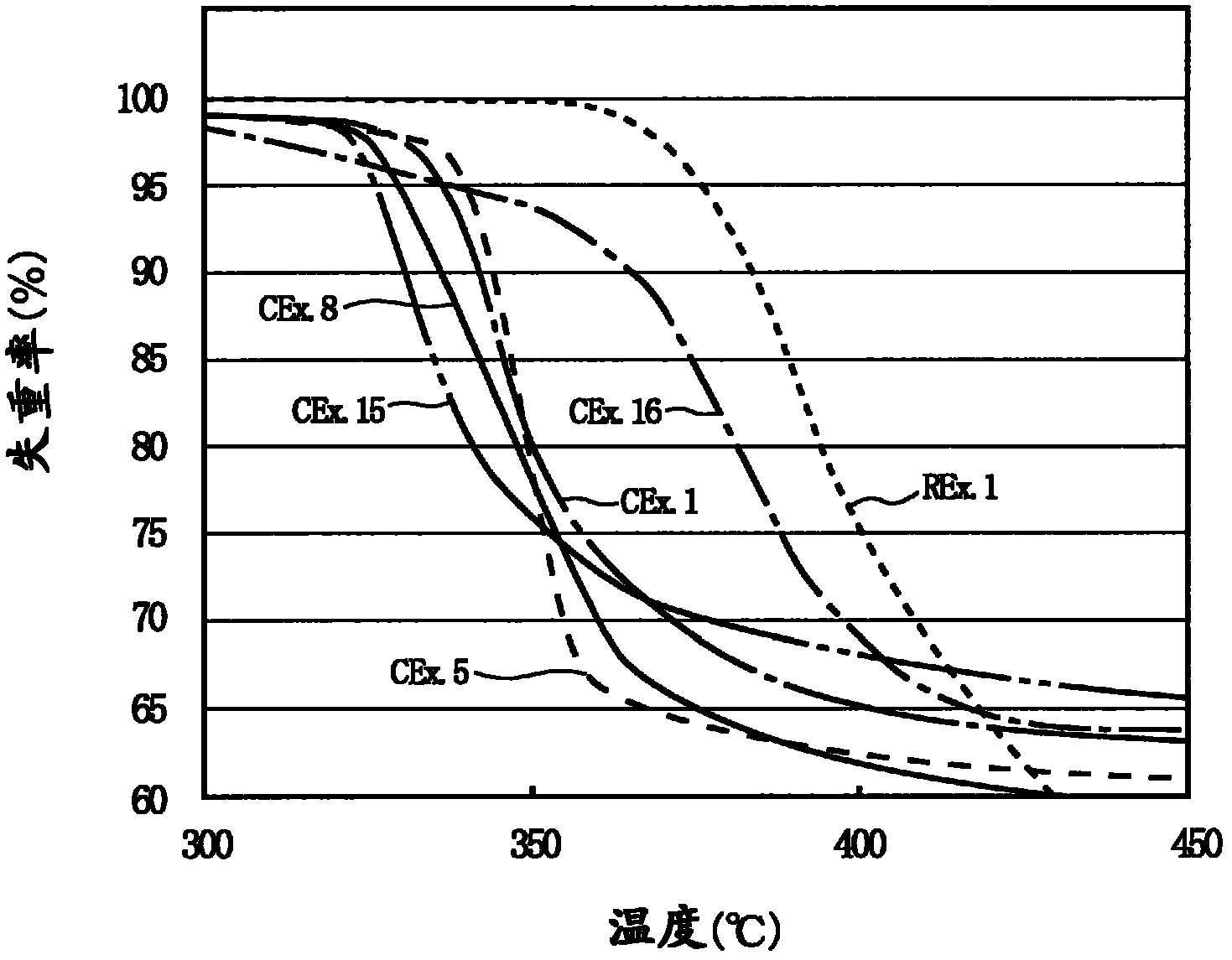

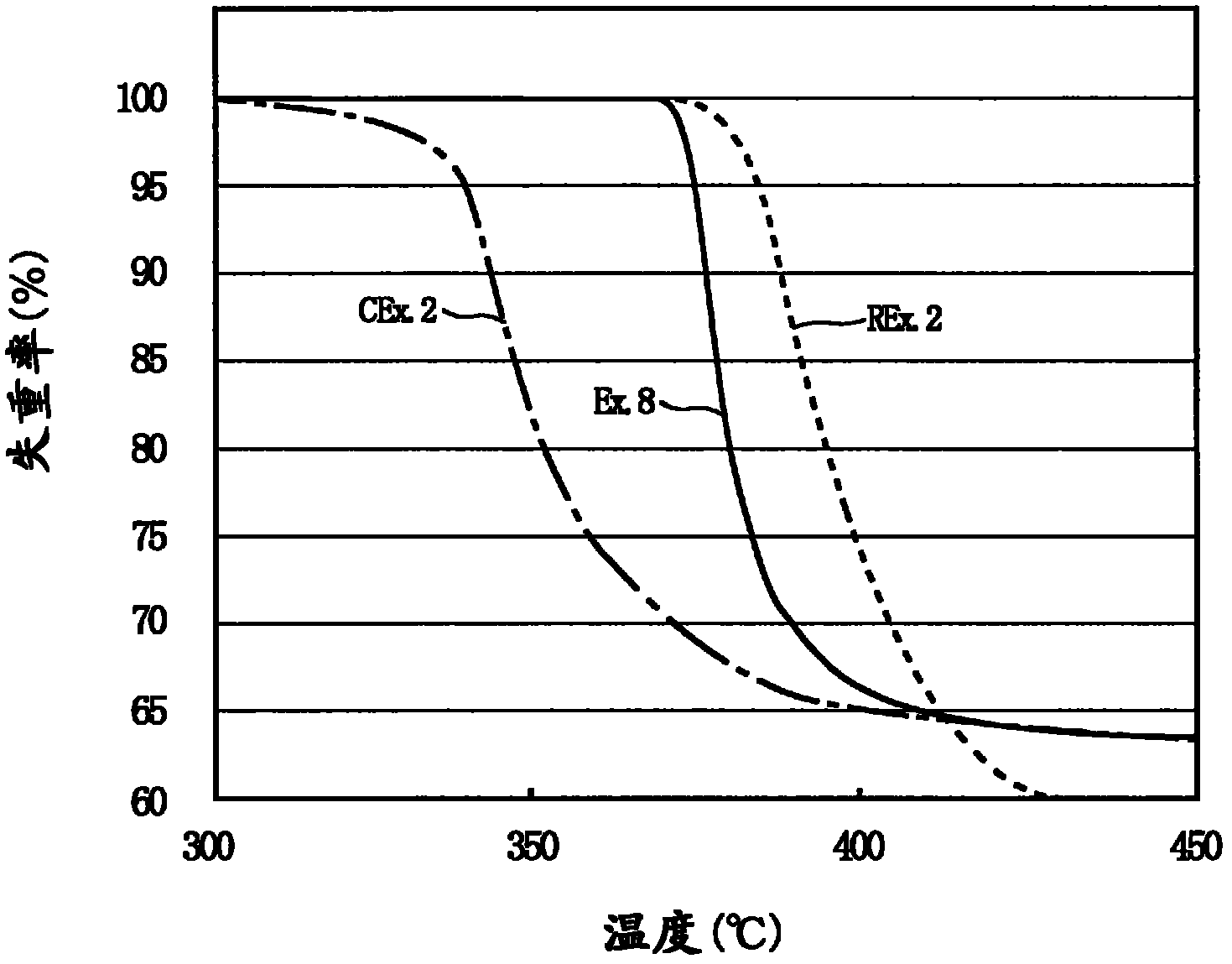

[0129] Examples are given below to illustrate the present invention more specifically. The methods for evaluating physical properties or characteristics are as follows.

[0130] (1) 10% thermal weight loss temperature

[0131] Using the Thermogravimetric Analyzer TC11 manufactured by Metro, put 20 mg of the sample that was vacuum-dried at 30°C for more than 6 hours into a platinum pan, and raise the temperature at 10°C / min in an atmosphere of 10 ml / min of dry nitrogen gas. The temperature was raised from 50°C to 450°C, and the weight loss rate was measured. The temperature at which the sample weight decreased by 10% by weight from the sample weight at the start of the measurement was defined as the 10% thermal weight loss temperature.

[0132] (2) Yellow index (YI) value

[0133] The YI value was measured in accordance with ASTM D-1925 using a color difference meter (ZE2000) manufactured by Nippon Denshoku Kogyo Co., Ltd.

reference example 1

[0135] When the 10% thermal weight loss temperature of polyvinylidene fluoride resin [KF (registered trademark) #850 manufactured by KLEHA Co., Ltd.; suspension polymer product] was measured, it was 382°C. The results are shown in Table 1.

reference example 2

[0137] The 10% thermal weight loss temperature of polyvinylidene fluoride resin [KYNAR (registered trademark) 720 manufactured by Alkema Corporation; emulsion polymer product] was measured and found to be 385°C. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com