Submicron powder Jinfang Baidu San normal temperature preparation method and special two-way airflow screen grader

A technology of Baidu powder and airflow sieve, which is applied in powder transportation, antiviral agents, pharmaceutical formulations, etc., can solve the problems of restricting the large-scale production of veterinary traditional Chinese medicine ultrafine powder, low bioavailability, and reduced pulverization efficiency. In large-scale industrial production, improve the rate of cell wall breaking, improve the effect of smell and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

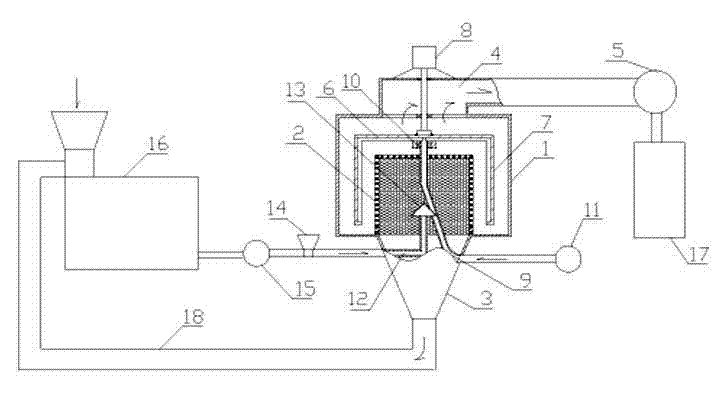

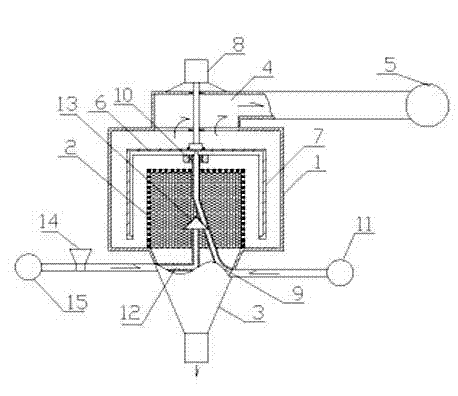

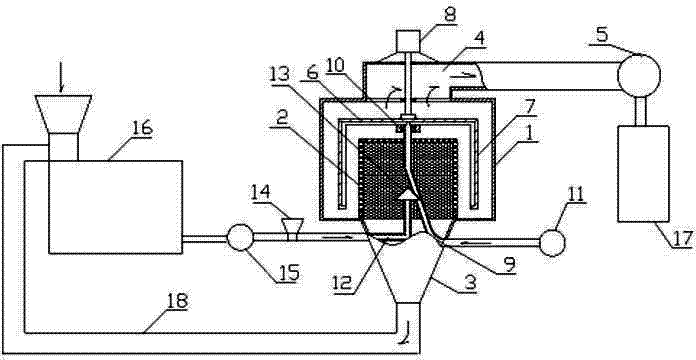

[0055] like figure 1 , 2 Shown, the normal temperature preparation method of superfine powder Jingfangbaidu powder of the present invention, comprises the following steps:

[0056] Step 1: Select raw materials Nepeta Nepeta, Fangfeng, Notopterygium, Duhuo, Bupleurum, Peucedanum, Fructus Aurantii, Poria, Campanulaceae, Chuanxiong, Licorice, Mint, wash, dry naturally, and cut into 3-5cm long sections , by natural drying or drying to a moisture content of ≤10%;

[0057] In the second step, the above raw materials are respectively pulverized at a temperature of 20° C. to 25° C. to obtain coarse powder of traditional Chinese medicine with a particle size of 60 to 80 meshes;

[0058] The third step is to prepare the coarse powder of the above-mentioned raw materials according to Nepeta: Fangfeng: Notopterygium: Duhuo: Bupleurum: Peucedanum: Citrus aurantium: Poria cocos: Campanulaceae: Chuanxiong: Licorice: Mint = 9:6:5:5:6:5 :6:9:6:5:3:3 are mixed evenly in parts by weight;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com