Method and device for recovering light hydrocarbon through refrigeration using compound refrigerant and secondary dealkylation

A composite refrigerant and light hydrocarbon recovery technology, which is applied in the recovery of liquid hydrocarbon mixtures, the petroleum industry, gas fuels, etc., can solve the problems of reduced liquid hydrocarbon production, reduced expansion efficiency, and increased equipment investment, so as to increase yield and replace Large thermal temperature difference and the effect of flexible load adjustment function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

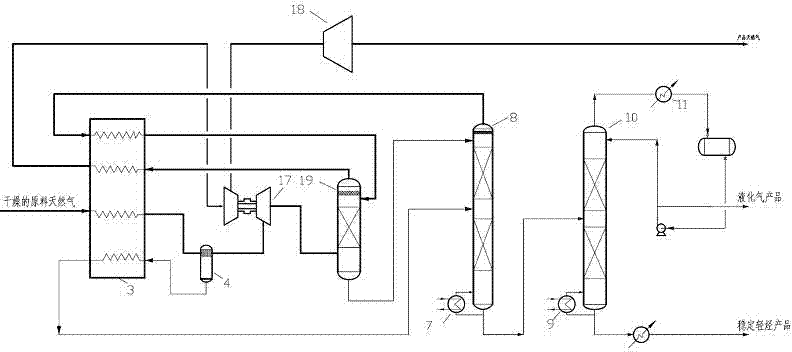

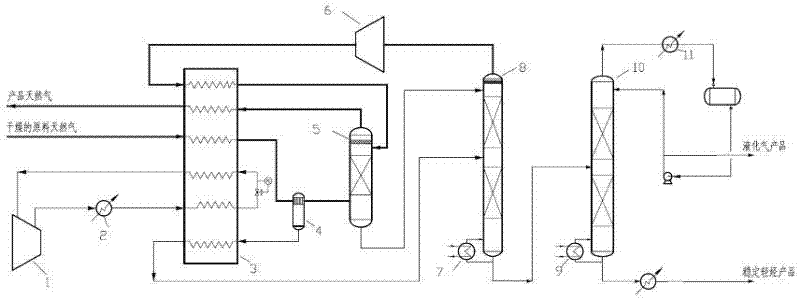

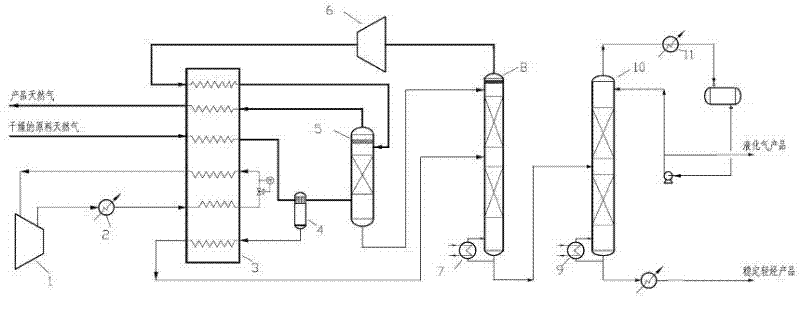

[0051] Such as figure 2 As shown, a composite refrigerant refrigeration secondary dehydrocarbon light hydrocarbon recovery device, including: composite refrigerant compressor 1, composite refrigerant cooler 2, main heat exchanger 3, low temperature separator 4, secondary dehydrocarbon tower 5. Deethanizer top gas compressor 6. Deethanizer reboiler 7. Deethanizer 8. Debutanizer reboiler 9. Debutanizer 10. Debutanizer condenser 11 Wait. in:

[0052] The main heat exchanger 3, the low-temperature separator 4, the secondary dehydrocarbon tower 5, the deethanizer 8 and the debutanizer 10 are sequentially connected; Feed port (can be directly connected, or can be connected through the main heat exchanger 3 first, so as to reheat and recover the cooling capacity of the liquid phase material); the gas phase outlet of the low temperature separator 4 is connected with the secondary dehydrogenation tower 5 ( It can be directly connected, or can be connected after passing through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com