Method for preparing alga inhibitor from barley

A technology of inhibitors and barley, applied in botany equipment and methods, herbicides and algicides, chemicals for biological control, etc., can solve problems such as restricting large-scale use, destroying the beauty of water bodies, and secondary pollution , to achieve good algae inhibition effect, good ecological security and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

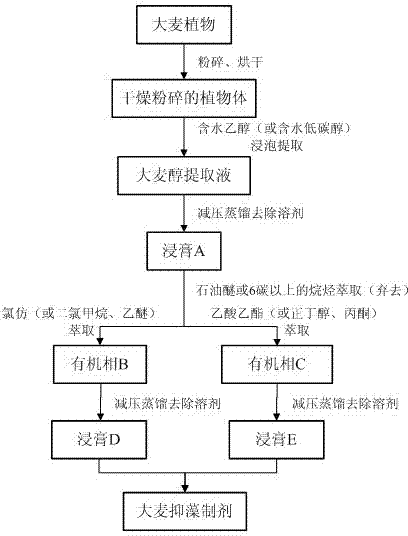

Method used

Image

Examples

Embodiment 1

[0022] Take 1.5 Kg of the aerial parts of barley and dry them at 65° C. for 48 hours to obtain dried plant materials. Take 300 grams of dried barley plants and crush them to 20 meshes, infiltrate them with 2 L of ethanol containing 75% alcohol, and extract them three times at 35°C for 2.5 hours each time to obtain ethanol extracts of barley. The ethanol extract of barley was distilled off under reduced pressure in a rotary evaporator at 45°C to obtain extract A. Take 10 grams of extract A, extract 3 times with petroleum ether, each dosage is 300ml, and remove the components that can be dissolved in petroleum ether in aqueous solution A. The remaining extract was extracted with chloroform four times, and the amount of chloroform each time was 400ml, and the chloroform phase B was obtained by separation. After four extractions with ethyl acetate, the amount of ethyl acetate used each time was 350 ml, and the ethyl acetate phase C was obtained by separation. Finally, the above-...

Embodiment 2

[0024] Take 1.5 Kg of above-ground parts of barley and dry them at 55° C. for 72 hours to obtain dried plant materials. Take 500 grams of dried barley plants and crush them to 50 meshes, infiltrate them with 3 L of aqueous methanol with an alcohol content of 70%, and extract them three times at 50°C for 3 hours each time to obtain barley ethanol extracts. The methanol extract of barley was distilled off under reduced pressure in a rotary evaporator at 40°C to obtain an extract A. Get 10 grams of extract A, extract 3 times with heptane, each dosage is 100ml, and remove the components that can be dissolved in heptane in extract A. The remaining extract was extracted with dichloromethane 3 times, and the amount of dichloromethane used each time was 100ml, and the dichloromethane phase B was obtained by separation. After three extractions with ethyl acetate, the amount of ethyl acetate used each time was 80 ml, and the ethyl acetate phase C was obtained by separation. Finally, t...

Embodiment 3

[0026] Take 1.5 Kg of the aerial parts of barley and dry them at 70° C. for 48 hours to obtain dried plant materials. Take 300 grams of dried barley plants and crush them to 50 meshes, infiltrate them with 2L of 80% ethanol in water, and extract them three times at 40°C for 2 hours each time to obtain barley ethanol extracts. The ethanol extract of barley was distilled off under reduced pressure in a rotary evaporator at 40°C to obtain extract A. Get 8 grams of extract A, extract 3 times with sherwood oil, each dosage is 120ml, remove the composition that can be dissolved in sherwood oil in extract A. The remaining extract was extracted with diethyl ether three times, each time the amount of diethyl ether was 150ml, and the diethyl ether phase B was obtained by separation. After 3 extractions with n-butanol, the amount of n-butanol was 120 ml each time, and the n-butanol phase C was obtained by separation. Finally, the ether phase B and n-butanol phase C were distilled off u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com