Preparation method for high resistivity bismuth ferric-barium titanate solid solution magnetoelectricity ceramic material

A technology of ceramic materials and high resistivity, which is applied in ferrimagnetic materials and ferroelectric fields, can solve the problems of low insulation resistivity, hysteresis loops that are difficult to appear saturated, weak magnetoelectric coupling effect, etc., and achieve electrical insulation performance Excellent, guaranteed consistent and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the ceramic material of the present invention is implemented according to the following steps.

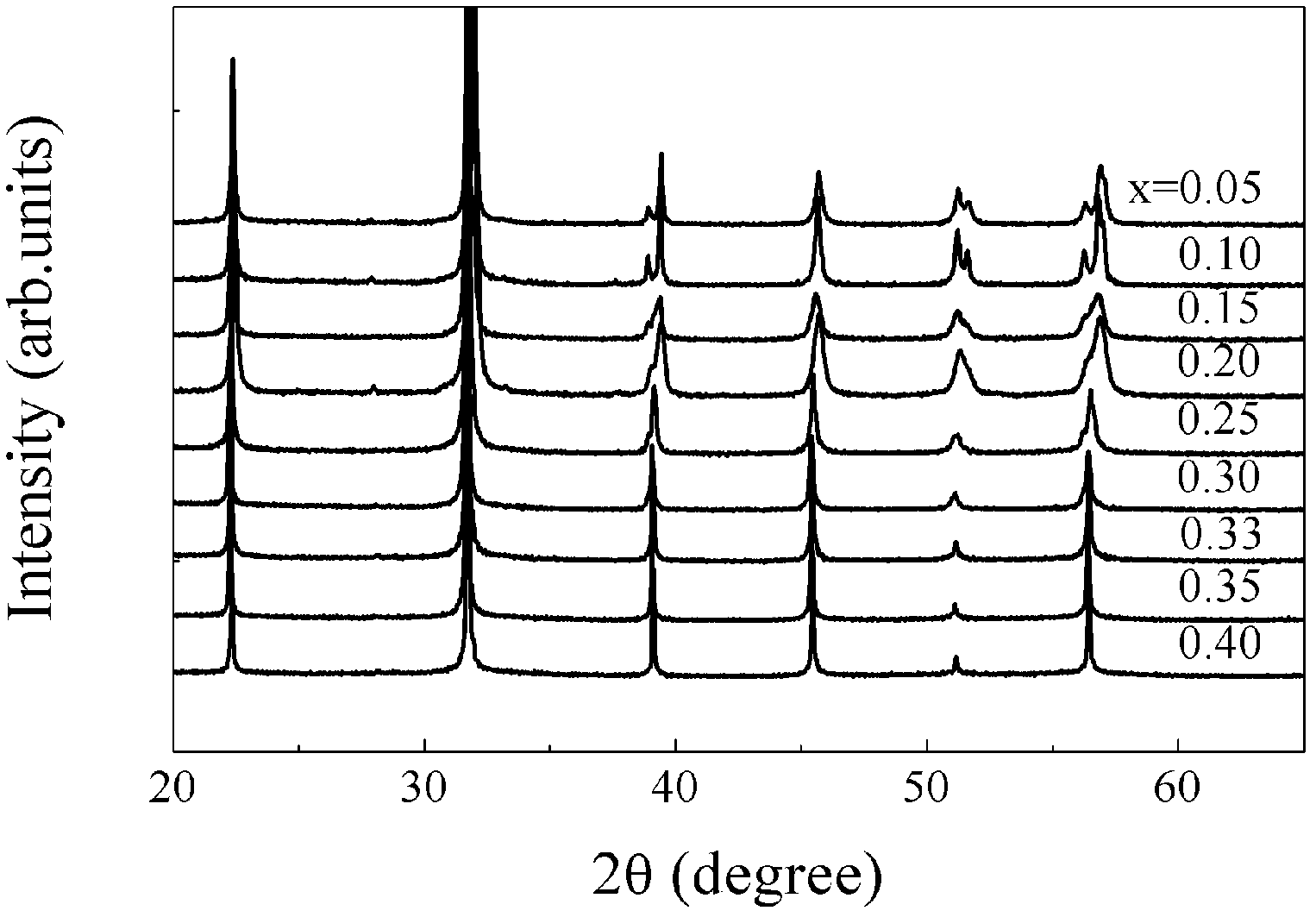

[0029] The first step, according to the general formula (1-x)BiFeO of ceramic material chemical composition 3 -xBaTiO 3 , where 0.05≤x≤0.40, the raw material is weighed according to the stoichiometric ratio of the material composition, wherein the raw material is an electronic grade chemical reagent Bi 2 o 3 , Fe 2 o 3 、TiO 2 and BaCO 3 , the material composition stoichiometric ratio is Bi 2 o 3 : Fe 2 o 3 :TiO 2 : BaCO 3 =(1-x) / 2:(1-x) / 2:x:x; Place the weighed raw materials in a nylon tank, add agate balls and liquid dispersion medium, and follow the raw materials, agate balls and liquid The weight ratio of the dispersion medium is 1:1:1, ball milling on a planetary ball mill for 6-8 hours to achieve full mixing, and place the mixed slurry in a constant temperature drying oven at 100°C±10°C for 2-4h; Wherein, the ball milling liquid di...

Embodiment 1

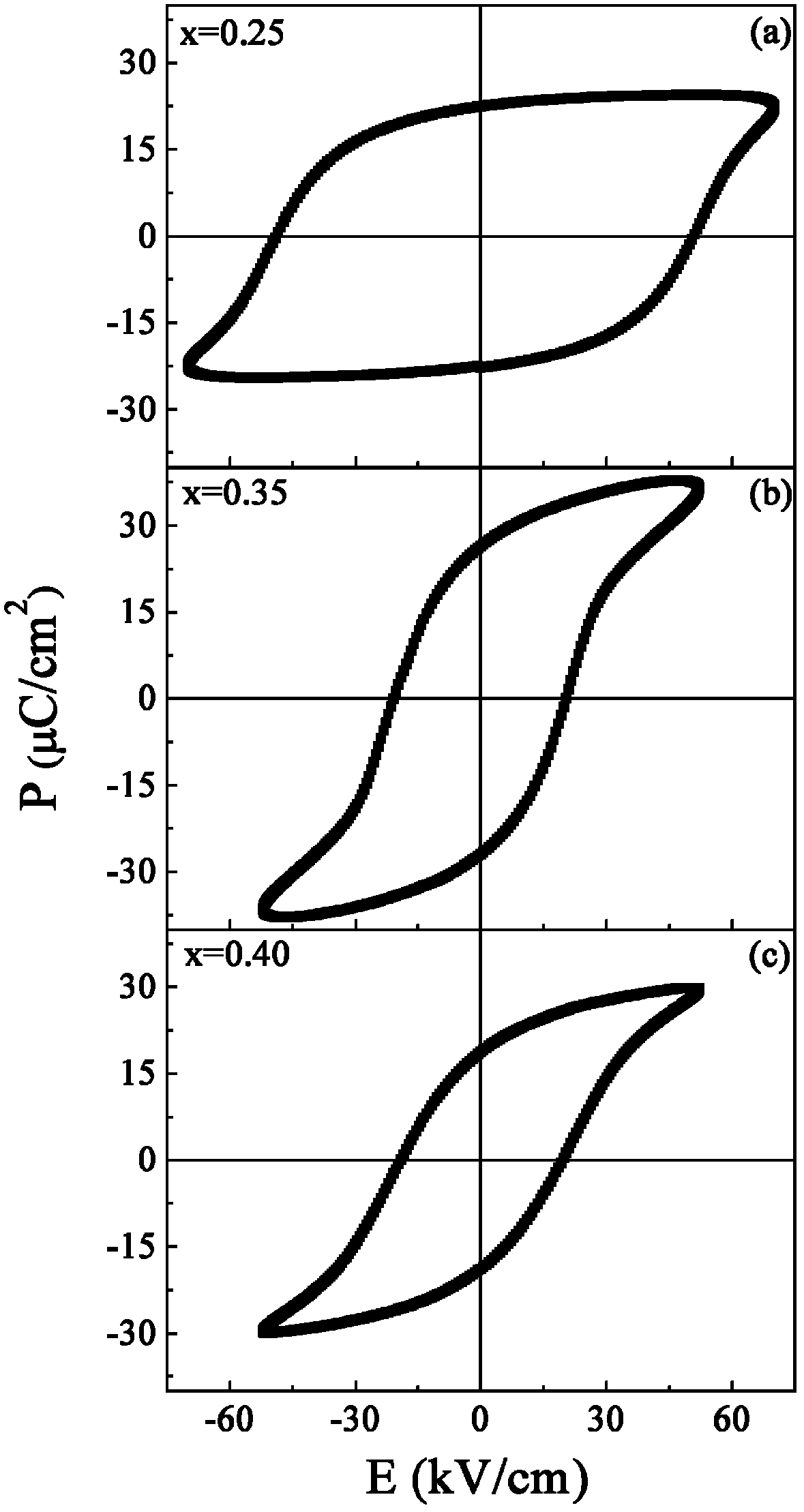

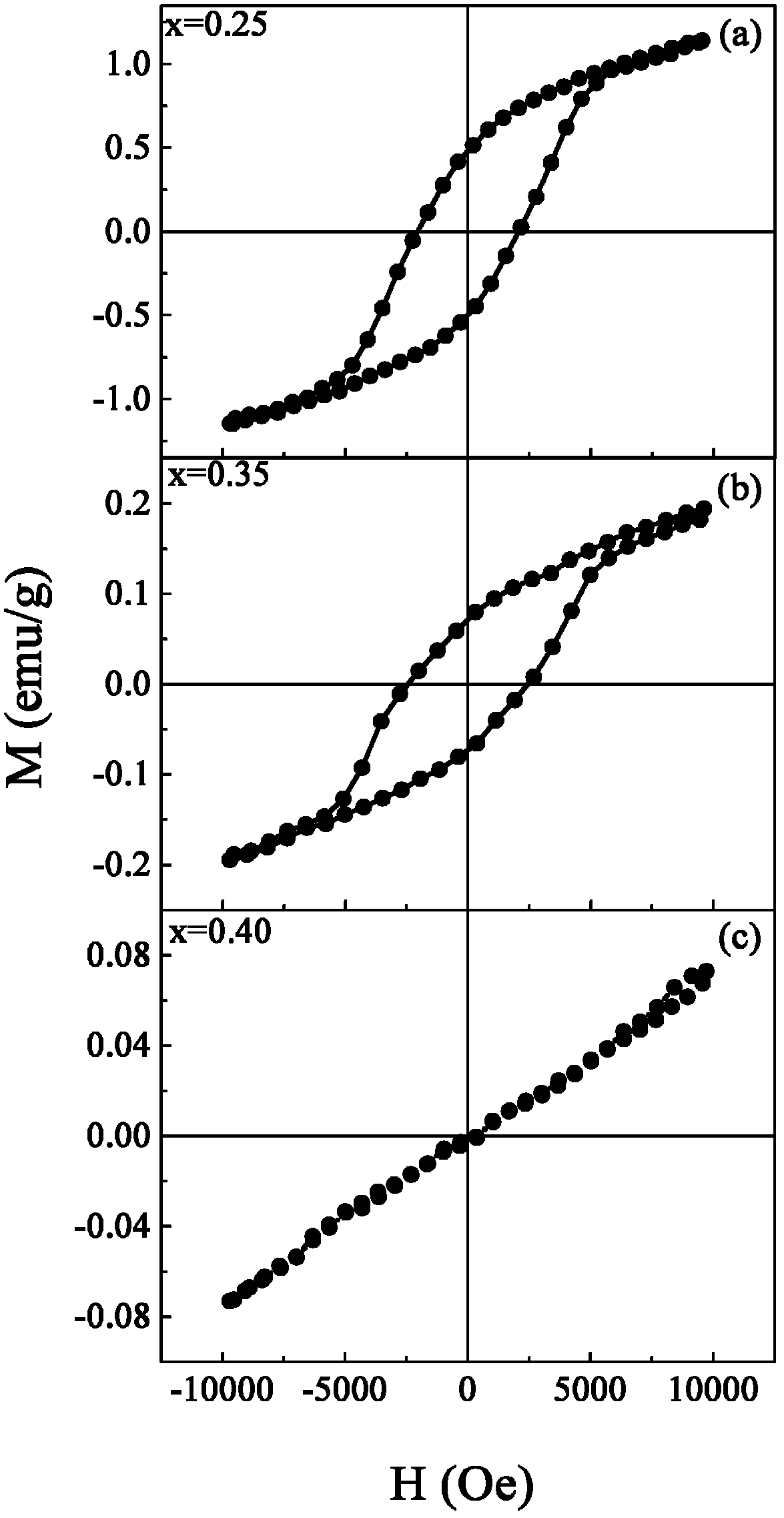

[0037] 1) By the general formula (1-x) BiFeO 3 -xBaTiO 3 The magnetoelectric solid solution ceramics indicated, when x=0.25, the ceramic material is 0.75BiFeO 3 -0.25BaTiO 3 , according to the stoichiometric ratio Bi of the chemical composition of the material 2 o 3 : Fe 2 o 3 :TiO2 : BaCO 3 = 0.375: 0.375: 0.25: 0.25 Weigh the raw materials; place the weighed raw materials in a nylon tank, add agate grinding balls and absolute ethanol, according to the weight ratio of raw materials, agate grinding balls and absolute ethanol is 1:1 : 1 ball milling on a planetary ball mill for 7 hours to achieve full mixing; place the mixed slurry in a constant temperature drying oven and dry at 100°C for 3 hours;

[0038] 2) Put the dried mixed powder into Al 2 o 3 In the crucible, cover it and put it in a box-type high-temperature electric furnace for pre-synthesis. The pre-synthesis temperature is 750 ° C, the holding time is 2 hours, and then it is naturally cooled with the furnac...

Embodiment 2

[0044] 1) By the general formula (1-x) BiFeO 3 -xBaTiO 3 The magnetoelectric solid solution ceramics indicated, when x=0.35, the ceramic material is 0.65BiFeO 3 -0.35BaTiO 3 , according to the stoichiometric ratio Bi of the chemical composition of the material 2 o 3 : Fe 2 o 3 :TiO 2 : BaCO 3 = 0.325: 0.325: 0.35: 0.35 Weigh the raw materials; put the weighed raw materials in a nylon tank, add agate grinding balls and absolute ethanol, according to the weight ratio of raw materials, agate grinding balls and absolute ethanol is 1:1 : 1 ball milling on a planetary ball mill for 6 hours to achieve full mixing; place the mixed slurry in a constant temperature drying oven and dry at 100°C for 3 hours;

[0045] 2) Put the dried mixed powder into Al 2 o 3 In the crucible, cover it and put it in a box-type high-temperature electric furnace for pre-synthesis. The pre-synthesis temperature is 820 ° C, the holding time is 2 hours, and then it is naturally cooled with the furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com