Gas heat carrier low-temperature retort furnace and dry quenching method

A gas heat carrier and dry distillation furnace technology, applied in the coal chemical industry, can solve the problems of short passage and poor thermal stability, and achieve the effects of small resistance in the furnace, stable material layer resistance and good gas quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

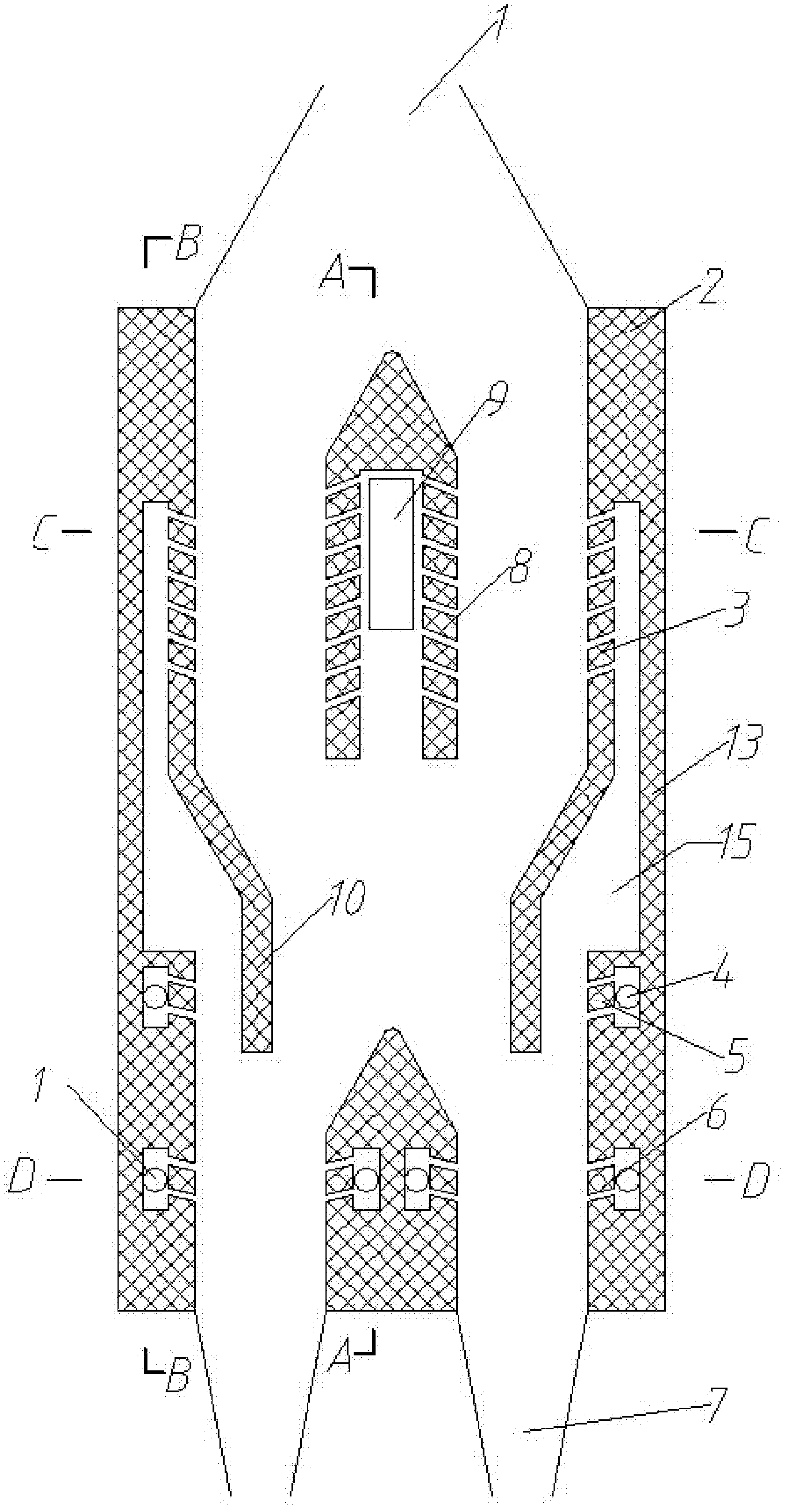

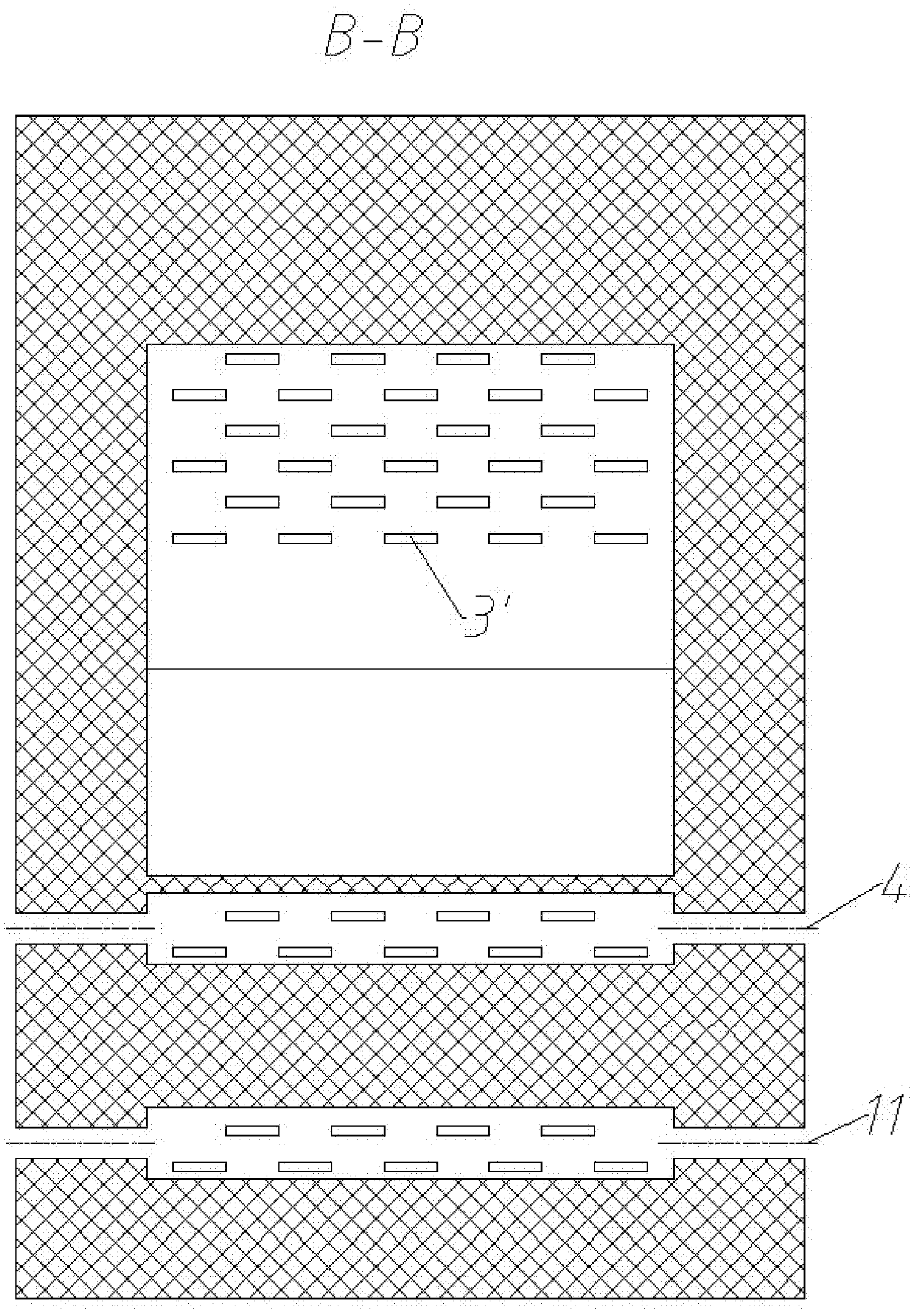

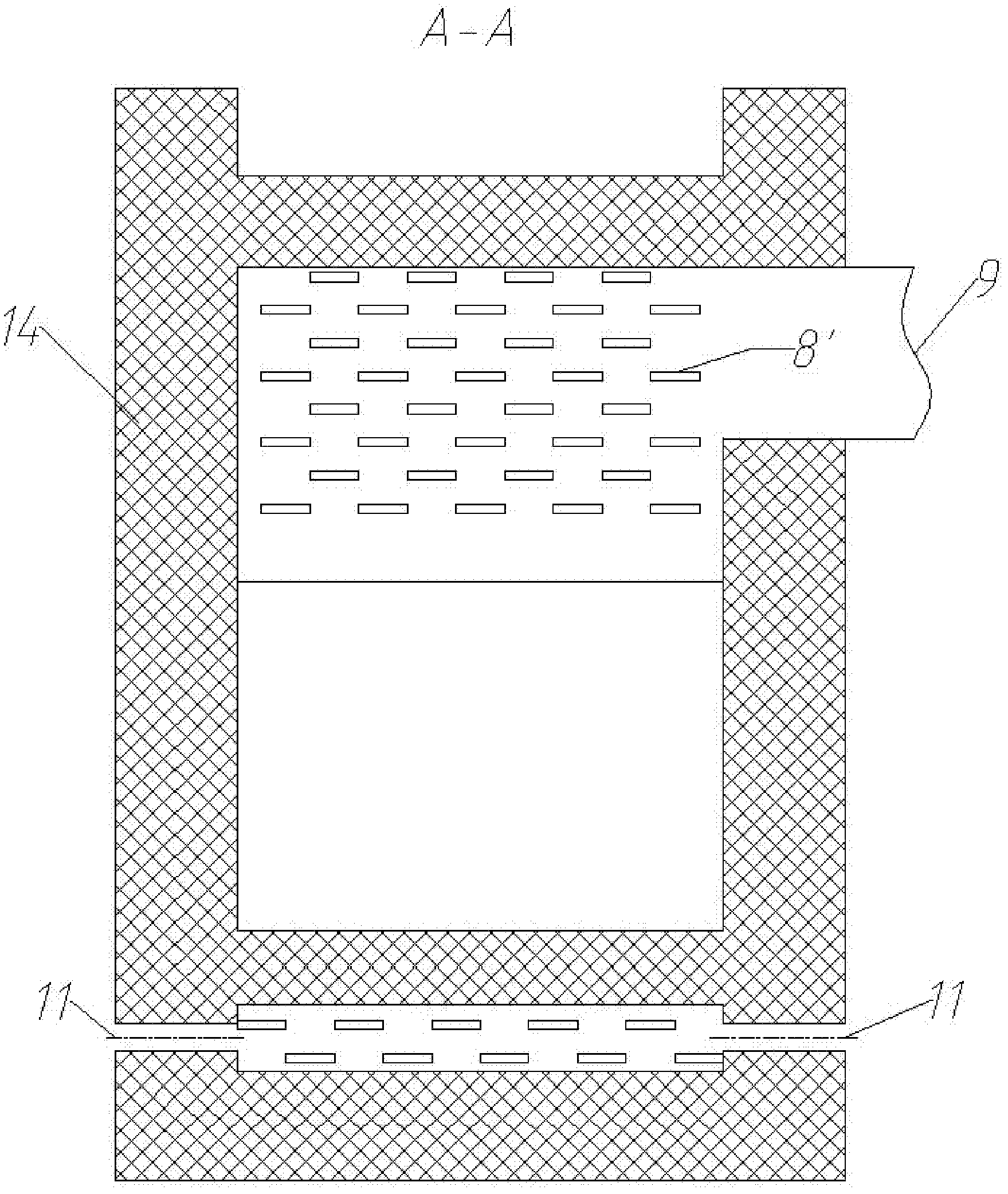

[0048] Embodiment 1: as Figure 8 , Figure 9 , Figure 10 As shown, this embodiment is a combination of basic structural units. Several basic structural units are combined in parallel to form a large retort furnace. There are two air gas mixture inlets and cooling gas inlets, and multiple gas outlets on the side of the furnace body, which are connected to the gas main pipe m and connected to the recovery system.

Embodiment 2

[0049] Embodiment 2: as Figure 11 As shown, this embodiment is a deformation of the basic structural unit, the structure of the material separation wall d changes as shown in the figure, the upper air inlet e is the air inlet, f is the cooling gas inlet, and the rising gas is at the part of the air outlet e Combustion is expected to complete the heating and cooling process. This basic structural unit also can form the large-scale carbonization furnace in the combination mode of embodiment 1.

Embodiment 3

[0050] Embodiment 3: as Figure 12 As shown, this embodiment is a modification of the basic structural unit. The air inlet a is the inlet of the mixed gas of coal gas and air, and the mixed gas is burned after being sprayed out. The air inlet b is the inlet of the mixed gas of air or air and gas. After spraying, it burns in the material layer to make the raw material reach the final temperature of dry distillation. The air inlet c is the inlet of the cooling gas. After the cooling gas is sprayed out, it rises through the material layer to cool the finished material and mixes with the gas emitted from the nozzle b to rise. , and then mixed with the combustion gas ejected from the nozzle a to an appropriate temperature to rise and enter the intake flower wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com