Method for preparing white carbon black from polysilicon byproduct silicon tetrachloride

A silicon tetrachloride and white carbon black technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of weakening product binding force, long reaction process, and low activity of white carbon black, so as to improve resource utilization and product quality. The quality, production equipment and process are simple to operate, and the effect of realizing environment-friendly production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

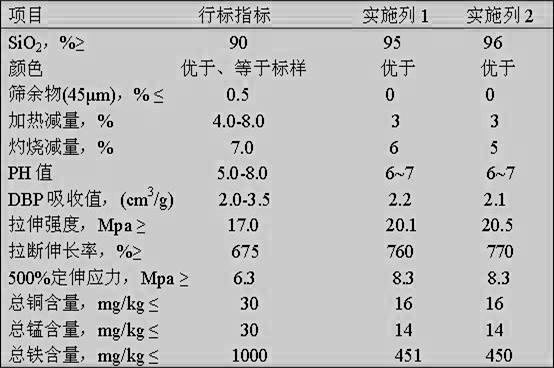

Embodiment 1

[0019] 1) Put silicon tetrachloride into the hydrolysis reaction kettle, carry out hydrolysis reaction at 30°C and normal pressure for 1 hour, filter the silicic acid gel and send it to the drum reactor, and HCl gas passes through the primary and secondary acid recovery kettles Water is absorbed and made into hydrochloric acid for subsequent use;

[0020] 2) Add sodium bicarbonate to the drum reactor from the feeding tank, control the mass ratio of silicic acid gel and sodium bicarbonate to 1:2, so that the alkali modulus of sodium bicarbonate is 2, add water to the drum reactor, water The mass is 20% of the sum of the mass of silicic acid gel and sodium silicate, the temperature is raised to 40°C, the drum reactor is turned on and mixed for 1 hour, and the insoluble impurities are separated by filtration to obtain a clear liquid;

[0021] 3) Send the clear liquid into the precipitation reaction kettle, add sodium dodecylbenzenesulfonate dispersant, the amount of sodium dodecy...

Embodiment 2

[0023] 1) Put silicon tetrachloride into the hydrolysis reactor, carry out the hydrolysis reaction at 50°C and normal pressure for 2 hours, filter the silicic acid gel and send it to the drum reactor, and HCl gas passes through the primary and secondary acid recovery kettles Water is absorbed and made into hydrochloric acid for subsequent use;

[0024] 2) Add sodium bicarbonate to the drum reactor from the feeding tank, control the mass ratio of silicic acid gel and sodium bicarbonate to 1:1, so that the alkali modulus of sodium bicarbonate is 3, add water to the drum reactor, water The mass is 50% of the sum of the mass of silicic acid gel and sodium naphthalene, the temperature is raised to 60°C, the drum reactor is turned on for a mixed reaction for 2 hours, and the insoluble impurities are separated by filtration to obtain a clear liquid;

[0025] 3) Send the clear liquid into the precipitation reaction kettle, add sodium dodecylbenzenesulfonate dispersant, the amount of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com