Humidity-sensitive polyimide, preparation and applications thereof

A technology of moisture-sensitive polyimide and maleimide-based polyimide, which is applied in the direction of fixed capacitor parts, etc., can solve problems such as non-moisture-sensitive polyimide films, and achieve good application prospects , simple operation, easy molecular weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

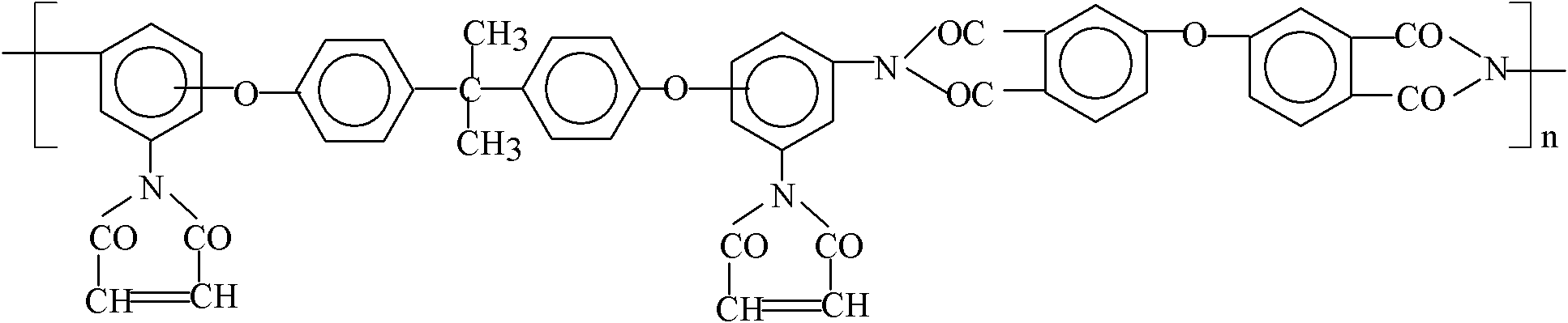

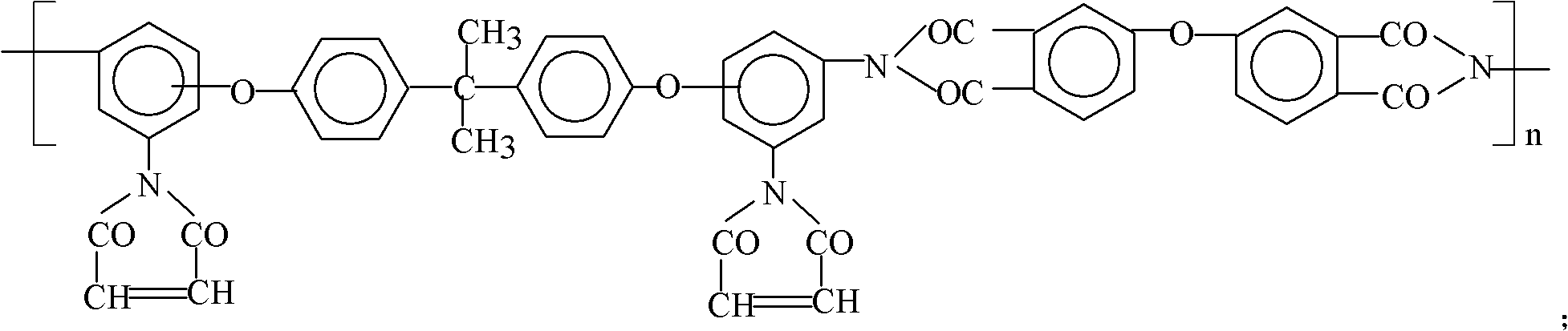

Method used

Image

Examples

Embodiment 1

[0051] Put 44.1 g (0.1 mol) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane and 400 ml of N-methyl-2-pyrrolidone strong polar aprotic organic solvent In the reactor, at room temperature, after stirring and dissolving completely, add 19.6 g (0.2 mol) of maleic anhydride solid powder, stir at room temperature until it is completely dissolved, continue to stir and react for 0.5 hours, add 31.0 g (0.1 mol) 3,3' ,4,4'-Tetracarboxydiphenyl ether dianhydride, stirred and reacted at 0℃-5℃ for 2 hours to obtain a homogeneous transparent viscous resin solution; add 200ml of toluene azeotropic dehydrating agent, azeotropic reflux water separation After stirring and reacting for 6-8 hours, add 4000 ml of ethanol, stir at high speed to precipitate solid powder, filter, wash 2-3 times with acetone, and dry in vacuum to obtain 86.2 g of maleimide-based polyimide powder (denoted as A component), the yield is 98.5%.

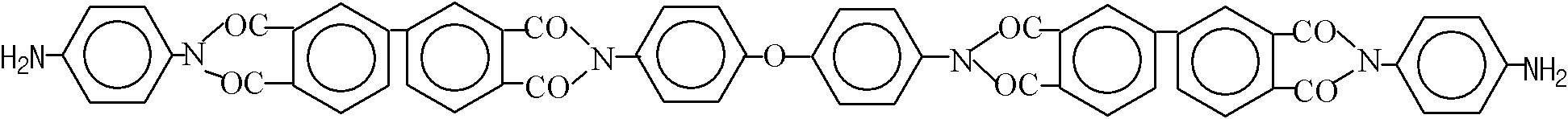

Embodiment 2

[0053] Put 20.0 g (0.1 mol) of 4,4'-diaminodiphenyl ether and 400 ml of N-methyl-2-pyrrolidone strong polar aprotic organic solvent into the reaction kettle, stir and dissolve at room temperature, then add 58.8g (0.2mol) 3,3',4,4'-tetracarboxybiphthalic anhydride solid powder, stirred for 0.5 hour at 0℃-5℃, added 21.6g (0.2mol) p-phenylenediamine powder, continue After stirring and reacting for 1 hour, a homogeneous transparent solution is obtained; adding 200 ml of toluene azeotropic dehydrating agent, nitrogen atmosphere, azeotropic reflux water separation, stirring for 5 hours, adding 4000 ml of ethanol, stirring at high speed, precipitation of solid powder, filtering, washing , Vacuum drying, 92.6 grams of amino-terminated imide oligomer powder (denoted as C component) was obtained, and the yield was 95.7%.

Embodiment 3

[0055] Take 15.0 grams of component A and 85.0 grams of chloroform, put them in a three-necked flask, stir to dissolve at room temperature, and obtain a solution of component A with a solid content of 15%; take 15.0 grams of component B (4,4'-bismaleyl Imino diphenylmethane) and 85.0 grams of chloroform were put into a three-necked flask, stirred and dissolved at room temperature to obtain a B component solution with a solid content of 15%; 15.0 grams of C component and 85.0 grams of chloroform were put into the three-necked flask In, stir and dissolve at room temperature to obtain a C component solution with a solid content of 15%;

[0056] Take 20.0 grams of component A solution, 2.0 grams of component B solution, and 8.0 grams of component C solution into a three-necked flask and stir evenly at room temperature to obtain a moisture-sensitive polyimide solution with a solid content of 15%, denoted as HSPI15 -31.

[0057] Take 20.0 grams of component A solution, 4.0 grams of comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com