High-dielectric low-loss imitation grain boundary layer capacitor and preparation method thereof

A technology of grain boundary layer and capacitor, applied in the direction of fixed capacitor electrode, fixed capacitor dielectric, fixed capacitor components, etc., can solve the problem of increased dielectric loss, reduce dielectric loss, cheap and easy to obtain raw materials, and expand selection range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

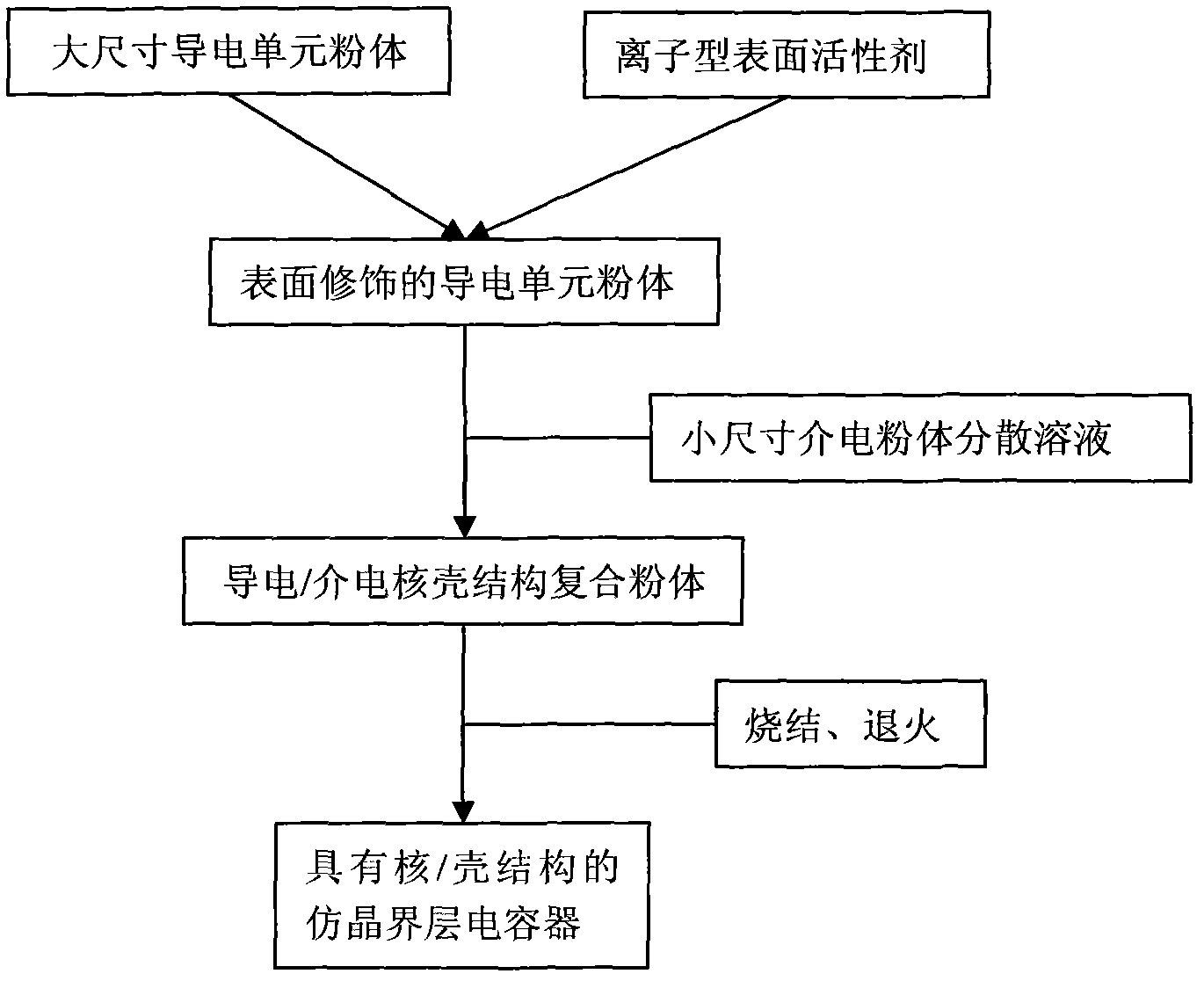

Method used

Image

Examples

Embodiment 1

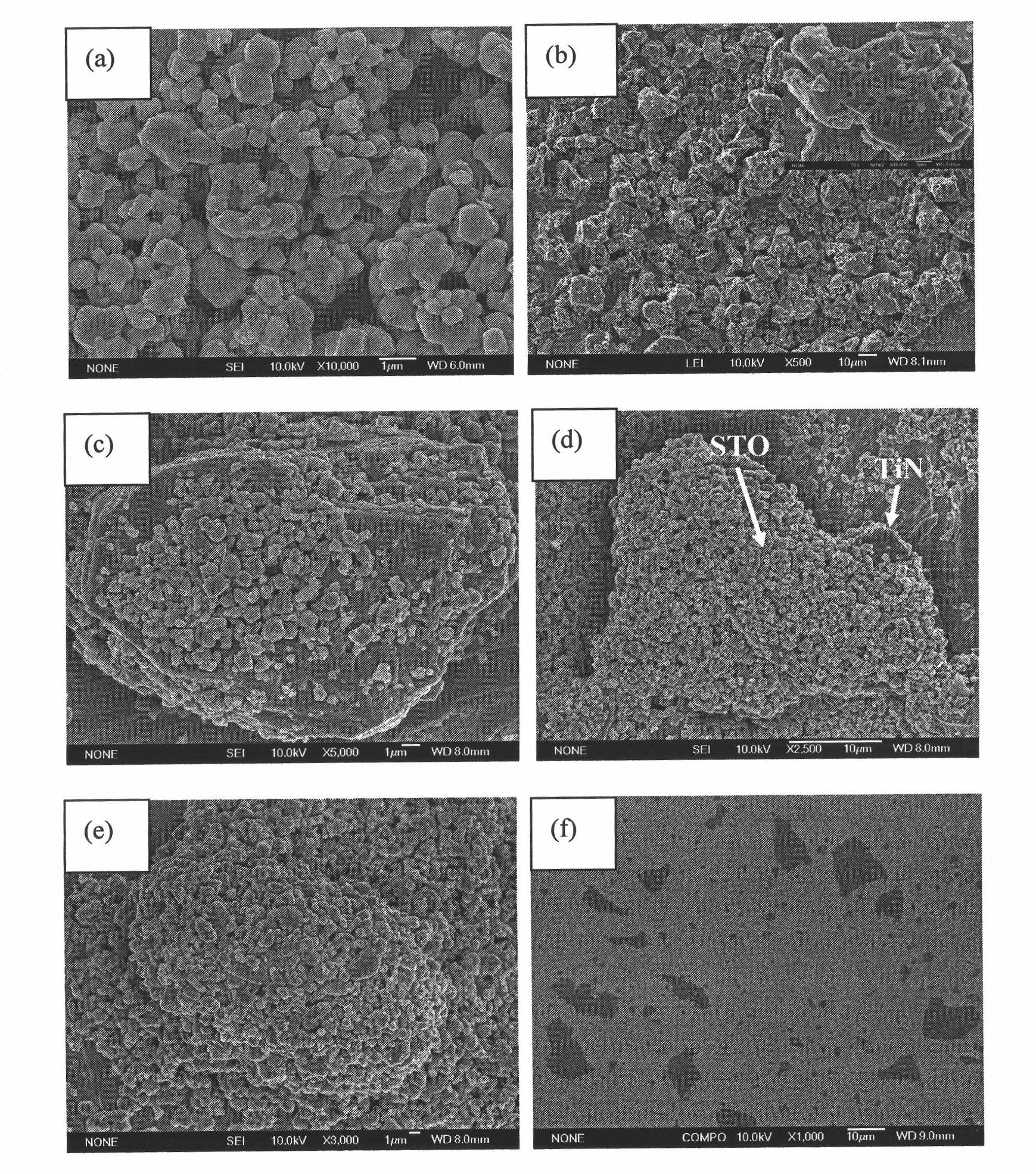

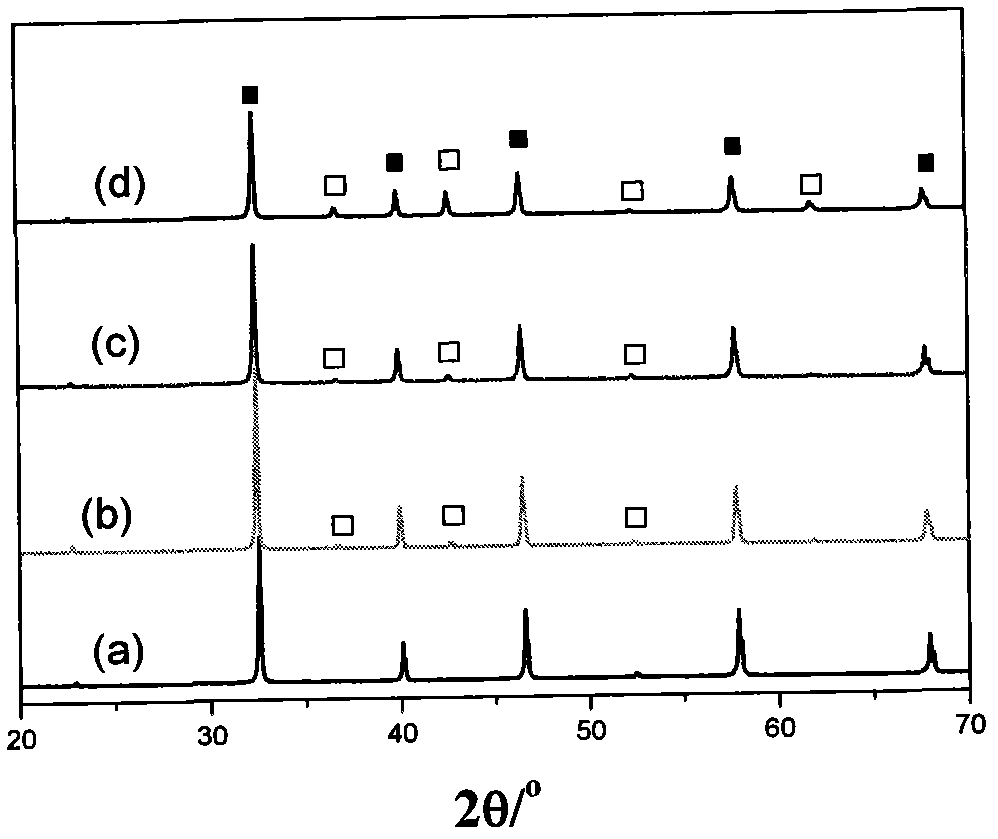

[0042] Choose a diameter of 1μm SrTiO 3 Powder ( figure 2 a) As a dielectric insulating shell material and 10μm TiN powder ( figure 2 b) As a conductive unit material. Prepare 1% PEI aqueous solution and adjust its pH from 11 to 5 with dilute acid to promote complete ionization of PEI. Add 1 mmol of 10 μm TiN powder into 100 mL of the above PEI solution, ultrasonically disperse for 1 hour, reflux at 110° C. for 4 hours, vacuum filter, and wash repeatedly with deionized water. The obtained product (TiN / PEI powder) was dried at 120° C. for use. Add 1mmol, 5mmol, and 25mmol of STO powder into 100mL of water, and ultrasonically disperse for 1 hour. Three parts of 1mmol TiN / PEI powder were ultrasonically dispersed in 50mL deionized water, slowly added to the STO solution under stirring at room temperature, ultrasonicated for 2 hours, stirred and refluxed at 110°C for 4 hours, vacuum filtered, dried at 120°C, 200 mesh sieve. The resulting product (TiN / SrTiO 3 Composite powd...

Embodiment 2

[0047] Choose a diameter of 1.5μm BaTiO 3 The powder is used as the dielectric insulating shell material and the 20μm ZrN powder is used as the conductive unit material. Prepare a 2% CTAB aqueous solution, add 1 mmol ZrN powder to 100 mL of the above CTAB solution, ultrasonically disperse for 4 hours, reflux at 100°C for 8 hours, vacuum filter, and repeatedly wash with deionized water to remove excess CTAB. The obtained product (ZrN / CTAB powder) was dried at 100°C for use. 1mmol, 10mmol, 20mmol of BaTiO 3 The powder was added into 100mL of water and ultrasonically dispersed for 1 hour. Three parts of 1mmol ZrN / CTAB powder were ultrasonically dispersed in 100mL deionized water, slowly added to the BTO solution under stirring at room temperature, ultrasonicated for 4 hours, refluxed at 100°C for 4 hours, vacuum filtered, washed with water, dried at 120°C, 200 Mesh sieve. The resulting product (BaTiO 3 / ZrN powder) SPS sintering, heat preservation at 1200°C for 5 minutes, an...

Embodiment 3

[0049] Select diameter 600nm Pb(Mg 1 / 3 Nb 2 / 3 )O 3 The powder is used as the dielectric insulating shell material and the 15 μm NbN powder is used as the conductive unit material. Prepare a 1% DDAB aqueous solution, add 1 mmol NbN powder to 100 mL of the above DDAB solution, ultrasonically disperse for 2 hours, reflux at 110°C for 8 hours, vacuum filter, and repeatedly wash with deionized water to remove excess DDAB. The obtained product (NbN / DDAB powder) was dried at 110°C for use. 0.5mmol, 5mmol, 10mmol of Pb (Mg 1 / 3 Nb 2 / 3 )O 3 The powder was added into 100mL of water and ultrasonically dispersed for 2 hours. Three parts of 1mmol NbN / DDAB powder were ultrasonically dispersed in 50mL deionized water, and slowly added to Pb(Mg 1 / 3 Nb 2 / 3 )O 3 In the solution, it was ultrasonicated for 4 hours, refluxed at 110°C for 10 hours, vacuum filtered, dried at 110°C, and sieved through a 200-mesh sieve. The resulting product (Pb(Mg 1 / 3 Nb 2 / 3 )O 3 / NbN powder) SPS sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com