Full-inorganic oxide high-efficiency quantum dot solar battery and manufacturing method thereof

A technology of inorganic oxides and solar cells, which is applied in the manufacture of circuits, electrical components, and final products. It can solve the problems of organic materials that are afraid of water, easy to oxidize, and unfavorable development and industrialization of quantum dot solar cells, and achieve oxidation resistance. Strong, overcoming poor stability, and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to complete the above content of the invention, the following are the specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings.

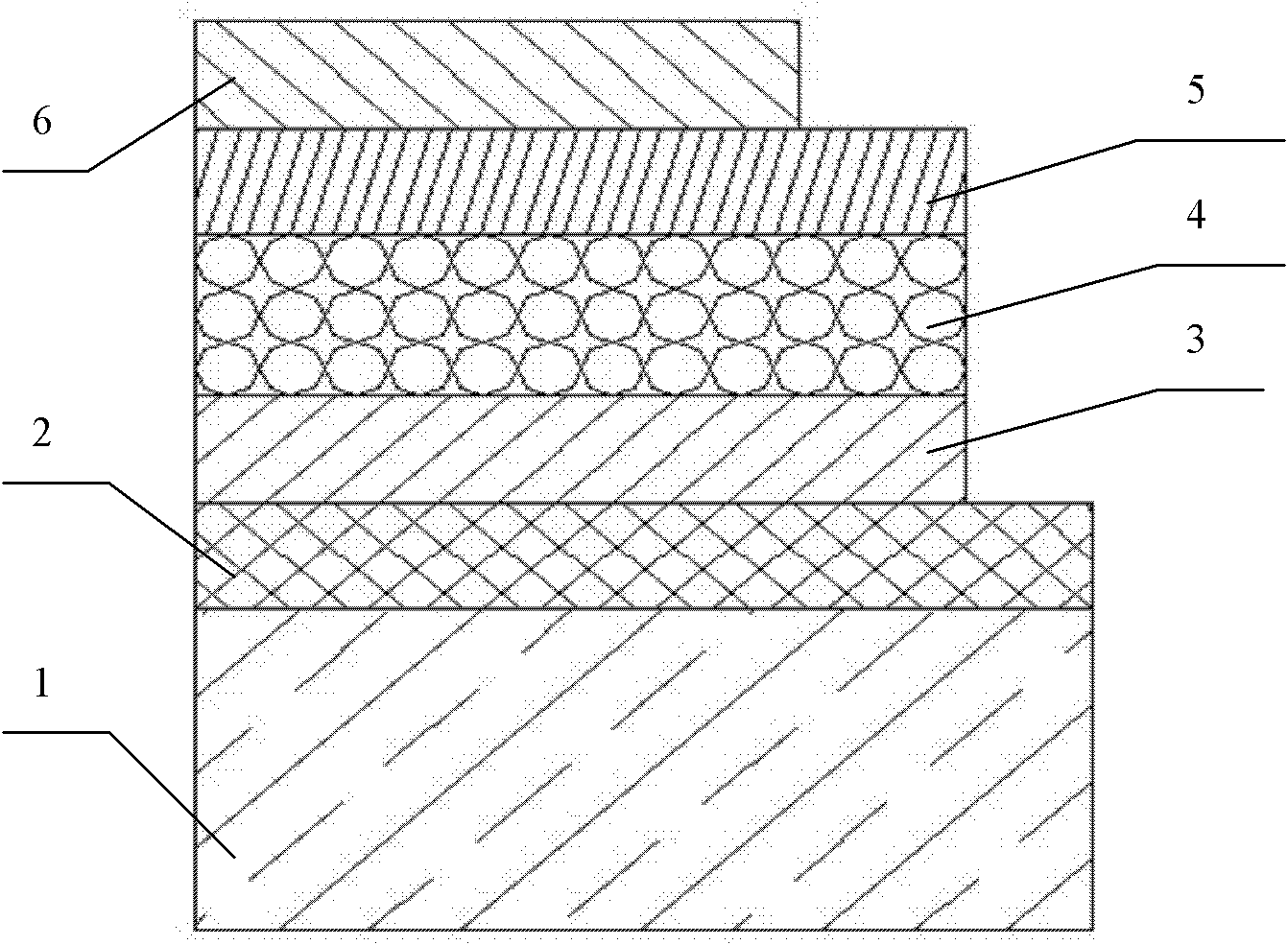

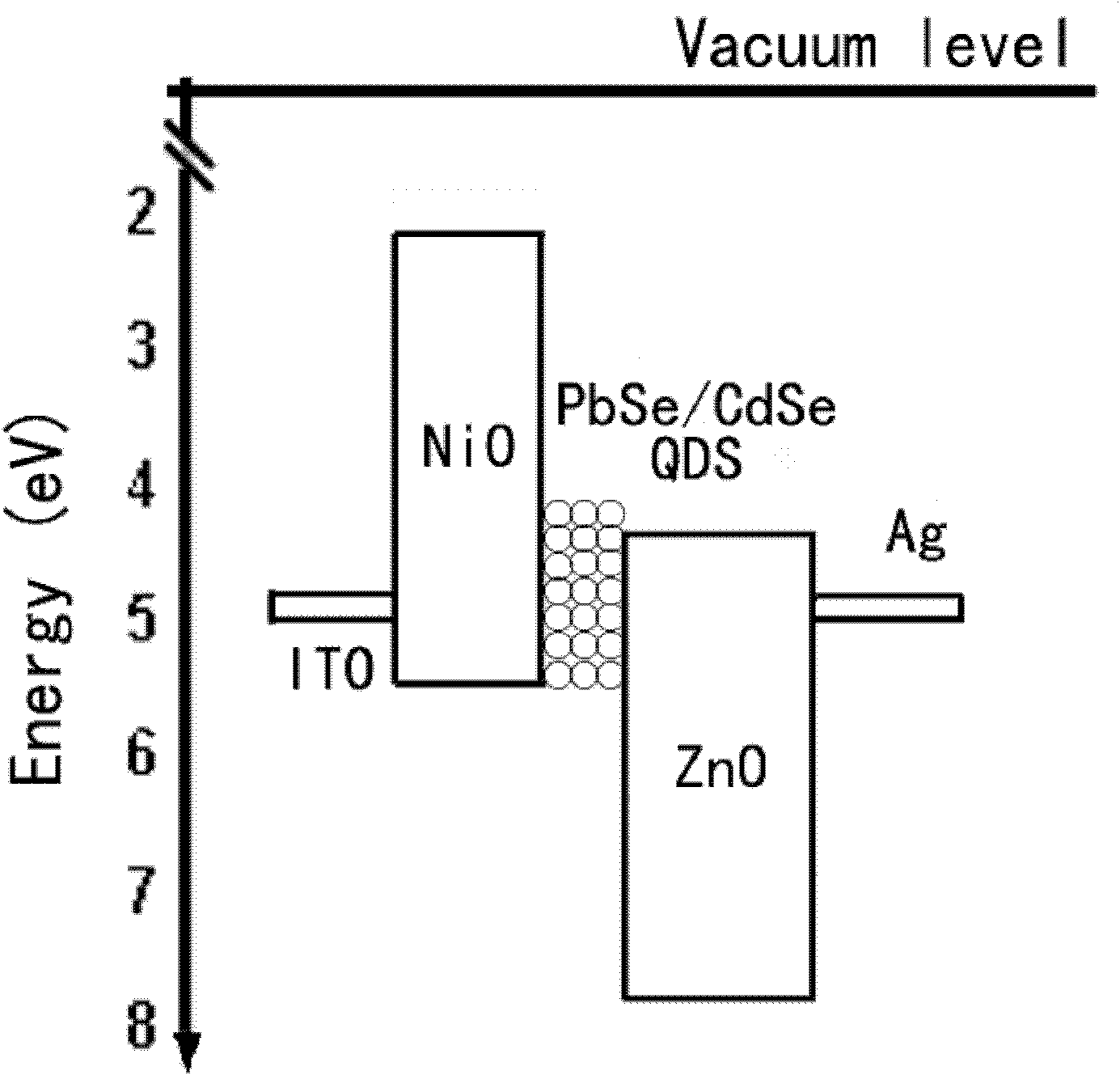

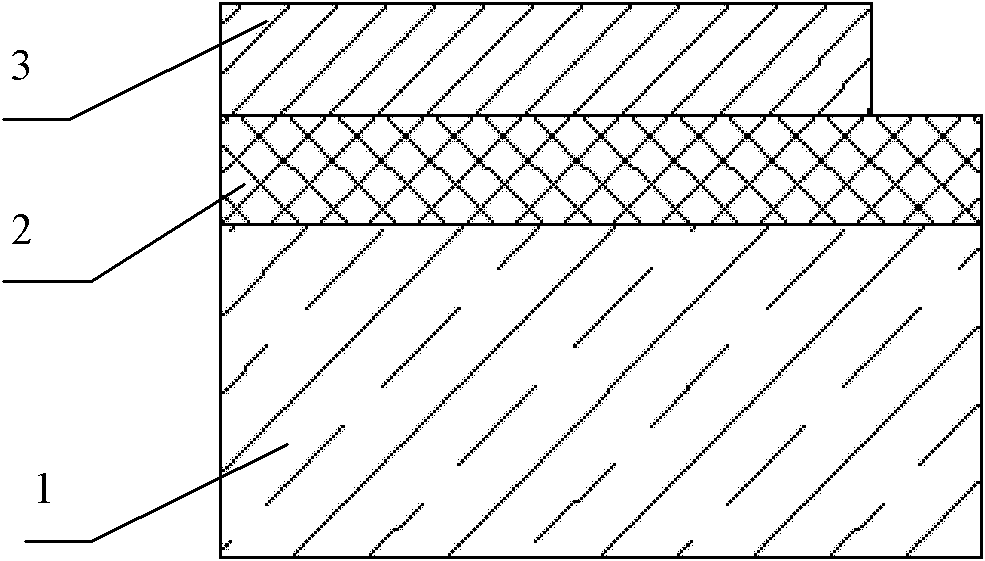

[0030] refer to figure 1 , PbSe / CdSe core-shell quantum dot thin film 4 forms a reasonable match with NiO thin film 3 and ZnO nano thin film 5 . Using NiO thin film 3 as the hole collection layer, its band gap depends on film thickness and other factors, and the highest occupied molecular orbital is generally around 5.4eV; using ZnO nano film 5 as the electron collection layer, its band gap depends on Factors such as the size of ZnO nanocrystal synthesis, the lowest unoccupied molecular orbital is generally around 4.3eV. The energy level diagram of its solar cell device is shown in figure 2 shown. In this way, the interface between the PbSe / CdSe core-shell quantum dot film 4 and the ZnO nanometer film 5 forms a heterojunction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com