Thin disk 515nm all-solid-state green laser

A laser and all-solid-state technology, applied to the structure/shape of optical resonators, can solve the problems of complex optical structure, large volume, difficult installation and adjustment, etc., and achieve the effect of good output stability, small volume and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

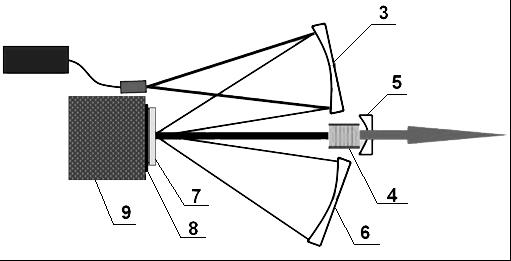

[0033] see figure 1 As shown, a thin-chip 515nm band all-solid-state green laser includes a pump source, a first spherical coupling mirror 3, an output coupling mirror 5, a second spherical coupling mirror 6, a gain medium 7, and a heat sink 9. The gain medium 7 is welded to the heat sink 9 through the welding layer 8;

[0034] The rear surface of the gain medium 7 and the concave surface of the output coupling mirror 5 form a plano-concave resonator, and the output coupling mirror 5 is located on the outgoing optical path of the gain medium 7;

[0035] The pumping source, the first spherical coupling mirror 3 and the second spherical coupling mirror 6 form a four-pass pumping optical coupling system, and the first spherical coupling mirror 3 and the pumping source are located on the plane On the same side of the concave resonator, the second spherical coupling mirror 6 is located on the other side of the symmetry of the first spherical coupling mirror 3, and the first spheri...

Embodiment 2

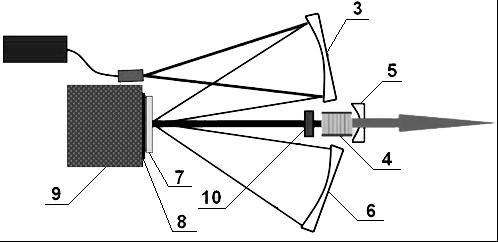

[0045] see figure 2 Shown is a schematic structural view of another embodiment of the thin-chip 515nm band all-solid-state green laser of the present invention. The structure of this embodiment is similar to that of Embodiment 1, except that a saturable absorber 10 is inserted in the cavity, and as the pump power increases, a fundamental frequency of 1030nm is generated in Yb-doped crystals such as laser gain medium Yb:YAG or Yb:LuAG Optical oscillation, when the fundamental frequency light passes through the saturable absorber 10, a 1030nm pulse laser is generated, and when the pulse laser 1030nm passes through the frequency doubling crystal 4 (KTP, LBO, BiBO, PPMgLN or other nonlinear crystals), due to the effect of nonlinear optical frequency doubling , so that 515nm pulsed laser output can be obtained.

Embodiment 3

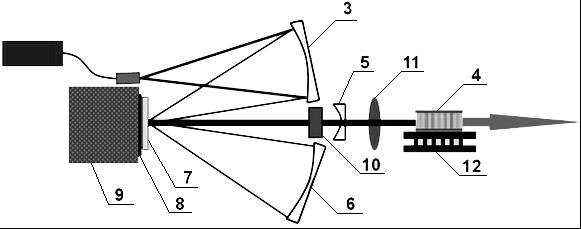

[0047] see image 3 As shown, it is a structural schematic diagram of another embodiment of the thin-chip 515nm band all-solid-state green laser of the present invention. The structure of this embodiment is similar to the coupling structure and resonant cavity type of embodiment 1, except that a saturable absorber 10 is inserted into the cavity, and a 515nm laser pulse output is obtained by frequency doubling outside the cavity.

[0048] The film system of the output coupling mirror 5 needs to be adjusted. It is required to prepare a 1030nm partial reflection film on the concave surface of the output coupling mirror 5, with a reflectivity of 70-80%. %, when the pump light exceeds the oscillation threshold power of the resonator with a wavelength of 1030nm, 1030nm fundamental frequency light is generated in Yb-doped crystals such as laser gain medium Yb:YAG or Yb:LuAG, and 1030nm is at the welding end face of gain medium 7 and Oscillation propagates between the concave surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com