Surface plasmon laser of semiconductor nanowire-metal film structure

A surface plasmon and metal thin film technology, applied in the field of nano optics, can solve problems such as the difficulty in reaching the excitation laser threshold, the inability to realize the resonance effect of long-wavelength visible light nano-laser, and the difficulty of sub-wavelength nano-laser.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

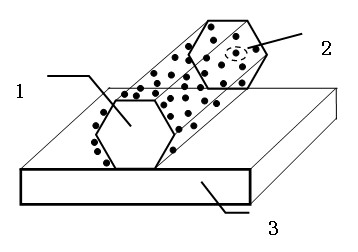

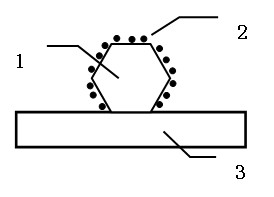

[0037] The surface plasmon laser of the semiconductor nanowire-metal thin film structure of the present embodiment mainly includes figure 1 , figure 2 Two structures, structure 1 includes solid semiconductor nanowires 1, quantum dots 2 and metal film 3, solid semiconductor nanowires 1 are closely attached to the surface of metal film 3, there is no gap between them, quantum dots 2 are distributed on solid semiconductor nanowires 1 surface.

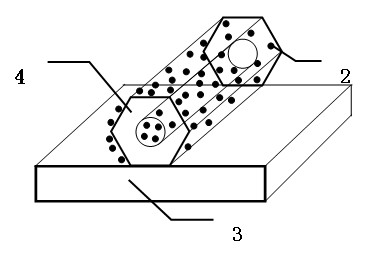

[0038] figure 2 The structure includes hollow semiconductor nanowires 4, quantum dots 2 and metal thin film 3, the hollow semiconductor nanowires 4 are closely attached to the surface of the metal thin film 3, there is no gap therebetween, and the quantum dots 2 are distributed on the outer surface and inner wall of the hollow semiconductor nanowires 4 superior. figure 2 The structure of the semiconductor nanowire is hollowed out by using technologies such as electron beam penetration to form a hollow nanowire 4, and quantum dots ar...

Embodiment 2

[0043] This example has Figure 8 , Figure 9 two structures, Figure 8 The structure includes a solid semiconductor nanowire 1, quantum dots 2 and a metal film 3, the quantum dots 2 are distributed on the surface of the solid semiconductor nanowire 1, there is a gap between the solid semiconductor nanowire 1 and the surface of the metal film 3, and at least A layer of quantum dots 2 .

[0044] Figure 9 The structure includes a hollow semiconductor nanowire 4, quantum dots 2 and a metal film 3, the quantum dots 2 are distributed on the outer surface and the inner wall of the hollow semiconductor nanowire 4, there is a gap between the hollow semiconductor nanowire 4 and the surface of the metal film 3, the gap There is at least one layer of quantum dots 2 distributed in it. Figure 9 The structure of the semiconductor nanowire is hollowed out by using technologies such as electron beam penetration to form a hollow nanowire 4, and quantum dots are distributed on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com