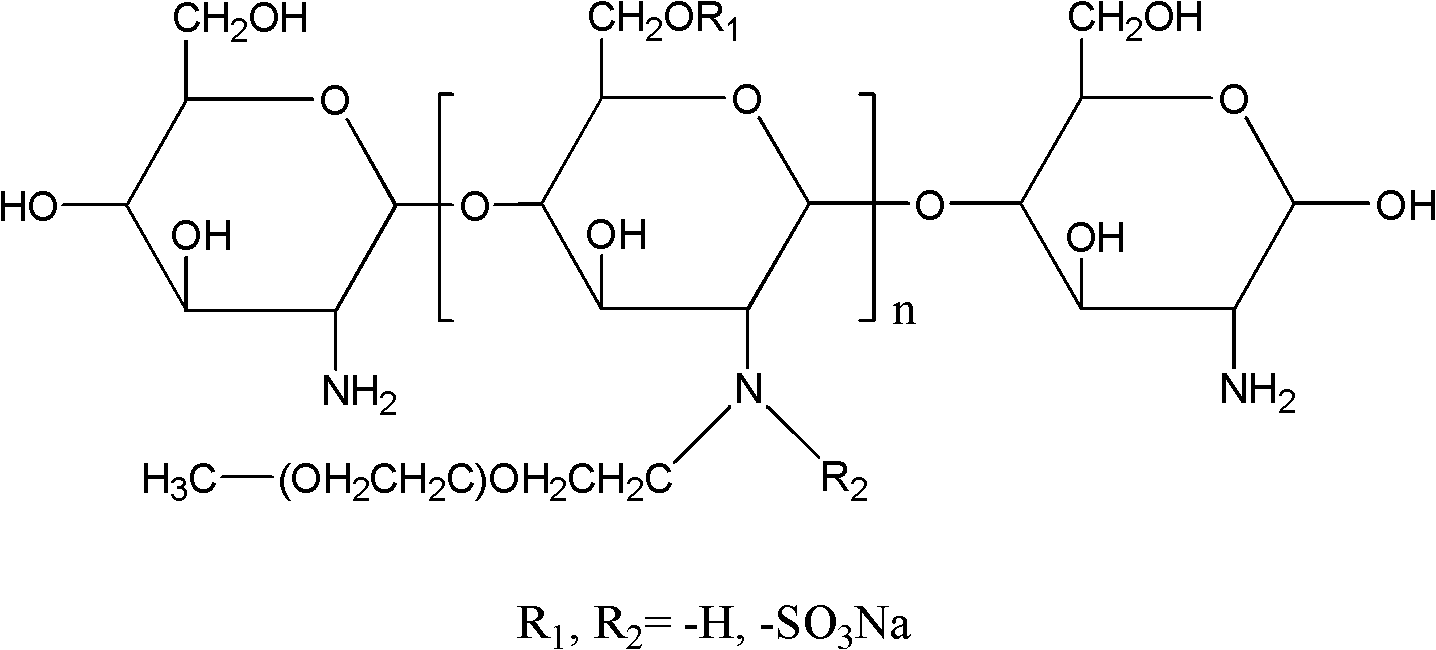

Method for preparing amphoteric chitosan water reducing agents

A technology of chitosan and water reducing agent, which is applied in the field of concrete water reducing agent, can solve problems such as covering problems, limited degree of problem solving, unevenness, etc., and achieves improved strength and durability, good slump retention, good The effect of flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1) Preparation of monomethoxy polyethylene glycol aldehyde derivatives

[0015] Dissolve 25 parts of polyethylene glycol monomethyl ether MPEG2000 in a mixed solution of 50 parts of dimethyl sulfoxide and 10 parts of chloroform in parts by mass, then add 10.2 parts of acetic anhydride, stir and react at 5°C for 12h, and the reaction The product was poured into 100 parts of ether for crystallization, filtered, and vacuum-dried at 40°C to obtain the monomethoxy polyethylene glycol aldehyde derivative, namely MPEGCHO2000;

[0016] 2) Preparation of N-monomethoxy polyethylene glycol chitosan (MPEGC2000)

[0017] Dissolve 1 part of soluble chitosan in 20 parts of methanol and 40 parts of mass concentration in a mixed solvent composed of 2% acetic acid aqueous solution in parts by mass, then add 2.27 parts of MPEGCHO2000, and then adjust it with 1mol / L sodium hydroxide The pH was 6.5, and then 11 parts containing 0.476 parts of sodium cyanoborohydride (NaCNBH 3 ) solution, ...

Embodiment 2

[0021] 1) Preparation of monomethoxy polyethylene glycol aldehyde derivatives

[0022] Dissolve 25 parts of polyethylene glycol monomethyl ether MPEG2000 in a mixed solution of 50 parts of dimethyl sulfoxide and 10 parts of chloroform in parts by mass, then add 12.66 parts of acetic anhydride, stir and react at 10°C for 11 hours, and the reaction The product was poured into 100 parts of ether for crystallization, filtered, and vacuum-dried at 40°C to obtain the monomethoxy polyethylene glycol aldehyde derivative, namely MPEGCHO2000;

[0023] 2) Preparation of N-monomethoxy polyethylene glycol chitosan (MPEGC2000)

[0024] Dissolve 1 part of soluble chitosan in 20 parts of methanol and 40 parts of mass concentration in a mixed solvent composed of 2% acetic acid aqueous solution in parts by mass, then add 3.33 parts of MPEGCHO2000, and adjust with 1mol / L sodium hydroxide The pH was 6.5, and then 12 parts containing 0.68 parts of sodium cyanoborohydride (NaCNBH 3 ) aqueous solu...

Embodiment 3

[0028] 1) Preparation of monomethoxy polyethylene glycol aldehyde derivatives

[0029] Dissolve 25 parts of polyethylene glycol monomethyl ether MPEG2000 in a mixed solution of 50 parts of dimethyl sulfoxide and 10 parts of chloroform in parts by mass, then add 14.12 parts of acetic anhydride, stir and react at 15°C for 10 h, and the reaction The product was poured into 100 parts of ether for crystallization, filtered, and vacuum-dried at 40°C to obtain the monomethoxy polyethylene glycol aldehyde derivative, namely MPEGCHO2000;

[0030] 2) Preparation of N-monomethoxy polyethylene glycol chitosan (MPEGC2000)

[0031] Dissolve 1 part of soluble chitosan in 20 parts of methanol and 40 parts of mass concentration in a mixed solvent composed of 2% acetic acid aqueous solution in parts by mass, then add 3.45 parts of MPEGCHO2000, and then adjust it with 1mol / L sodium hydroxide The pH was 6.5, and then 13 parts containing 0.79 parts of sodium cyanoborohydride (NaCNBH 3 ) solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com