Magnesium air battery cathode

An air battery and cathode technology, applied in battery electrodes, circuits, electrical components, etc., to achieve good catalytic performance, high selectivity, and easy purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

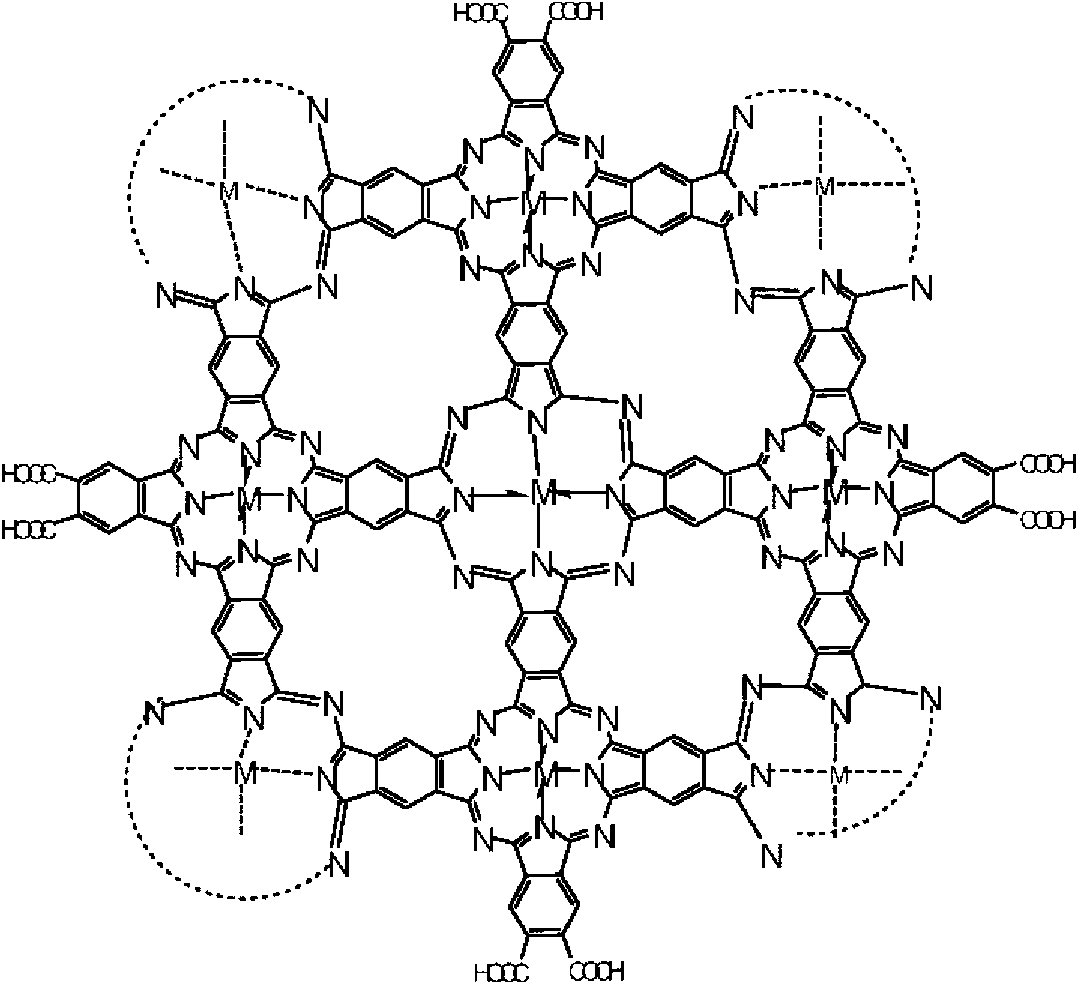

[0031] Example 1: Preparation of closely arranged planar polymerized phthalocyanines

[0032] (1) Liquid phase method

[0033] In a 250mL three-neck flask equipped with electric stirring, reflux condenser and thermometer, add 15.2g (0.1mol) urea, 8g (0.04mol) pyromellitic anhydride and 150mL rectified kerosene respectively, heat, and control the temperature at 170- 180°C, during the reaction process, the urea condensed and attached to the spherical condenser should be removed in time, react for 3 hours, stop heating, wait to cool below 140°C, add 0.5g (0.0004mol) ammonium molybdate, 7g ferrous ammonium sulfate (0.018mol ) and 15g (0.1mol) urea, speed up the stirring speed to prevent the reaction product from forming balls, control the temperature at 190-210°C for 4 hours, pour out the kerosene, take out the dark green crude product, use petroleum ether to eliminate the residual kerosene, grind it finely , boiled repeatedly, unreacted urea, metal salts and catalysts were washe...

Embodiment 2

[0040] Catalyst immobilization: Take the catalyst immobilization with a mass ratio of activated carbon and iron complexes of 1:1 as an example.

[0041] Add 0.50g Poly-PcFe and 20mL DMSO to the Erlenmeyer flask respectively, stir and heat to dissolve. Add 0.50g of XC-72 activated carbon, ultrasonically vibrate for 1h, then heat, reflux, and stir for 24h. Take the mixture out and put it into a beaker, place it on a heating mantle to evaporate until it dries quickly, put it in an oven for aging at 75°C, and dry it for later use.

[0042] The immobilization methods and steps of the catalysts with different proportions are the same as above, only the mass proportion of the polymerized phthalocyanine metal complex and activated carbon can be changed to prepare a catalyst with Poly-PcM:C=1.2:1-1:1.2.

[0043] The preparation method of the complexes (Poly-PcM) of different transition metal ions (Co2+, Ni2+, Mn2+, Pt2+, etc.), and the catalyst precursors with different mass ratios of...

Embodiment 3

[0045] Catalyst activation. Take the catalyst with a ratio of 1:1 (Poly-PcFe:C) activated at 600°C as an example.

[0046] Weigh 0.2500g of the immobilized catalyst, spread it evenly in the porcelain boat, place the porcelain boat in the quartz tube in the tubular resistance furnace, assemble and connect the experimental equipment, and confirm that the pipeline of the instrument is closed. Introduce high-purity Ar gas for 30 minutes, remove the air in the tube, continue to infuse Ar, and raise the temperature according to the set program. After the temperature rises to 600 ° C, keep the constant temperature for 2 hours, and then cool down. The whole process is continuously protected by argon to prevent the catalyst from being oxidized and decomposed at high temperature.

[0047] Catalysts with activation temperatures of 500° C. to 1100° C. can be obtained according to the above method, but the temperature of the heat preservation is different. Optional insulation 500°C, 700°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com