Preparation method of structure-enhanced silver/copper antibacterial zeolite and product prepared from structure-enhanced silver/copper antibacterial zeolite

A zeolite modification technology, which is applied in botany equipment and methods, crystalline aluminosilicate zeolite, chemicals for biological control, etc., can solve the problems of poor durability, fragility, shedding and preparation costs, and achieve Effects of high thermal stability and mechanical strength, good hardness, and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

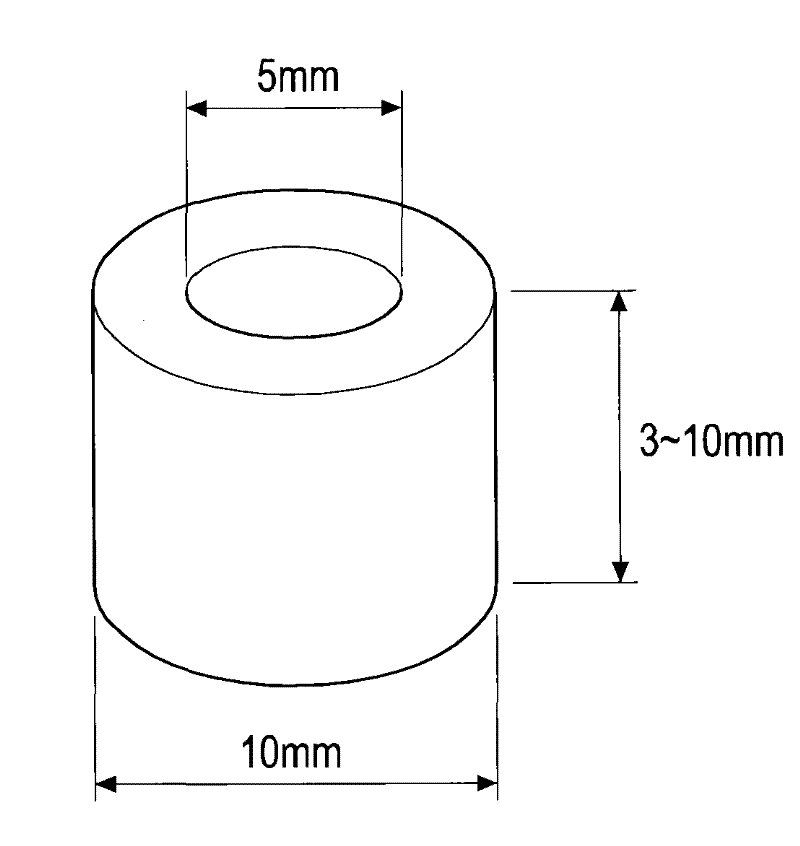

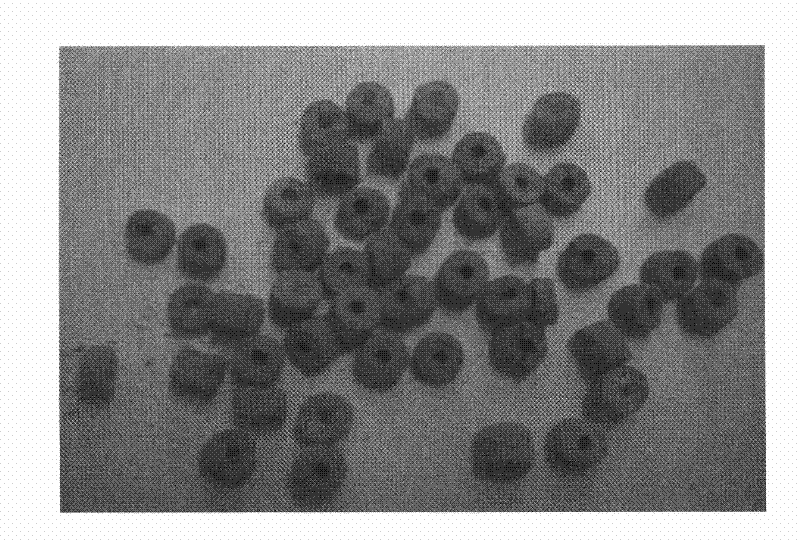

[0036] Get 35% Y type zeolite (USY, Sodium silica aluminate Z-14, Grace Davison company manufactures) and 65% SiO 2 After mixing, add 70% (Y-type zeolite + SiO 2 ) and 30% modifier uniformly mixed, and heated with 0.75M sodium hydroxide for 50 minutes by the hydrothermal method to carry out the gelation process to obtain the zeolite colloid, put the zeolite colloid into a mold, and squeeze the zeolite colloid by means of oil pressure into a hollow columnar shape, then dried at 100°C for 8 hours, and calcined at 450°C for 8 hours to prepare a structurally strengthened hollow columnar zeolite. The above percentages are all by weight. Its silicon-aluminum ratio (Si / Al) is 17, and its BET specific surface area is 482m 2 / g. The size of the gained hollow columnar zeolite is as follows figure 1 As shown, the finished product is as image 3 shown.

[0037] Take 1.6g of silver nitrate and 3g of copper nitrate and dissolve them in 350mL of deionized water, and shake them in an ult...

Embodiment 2

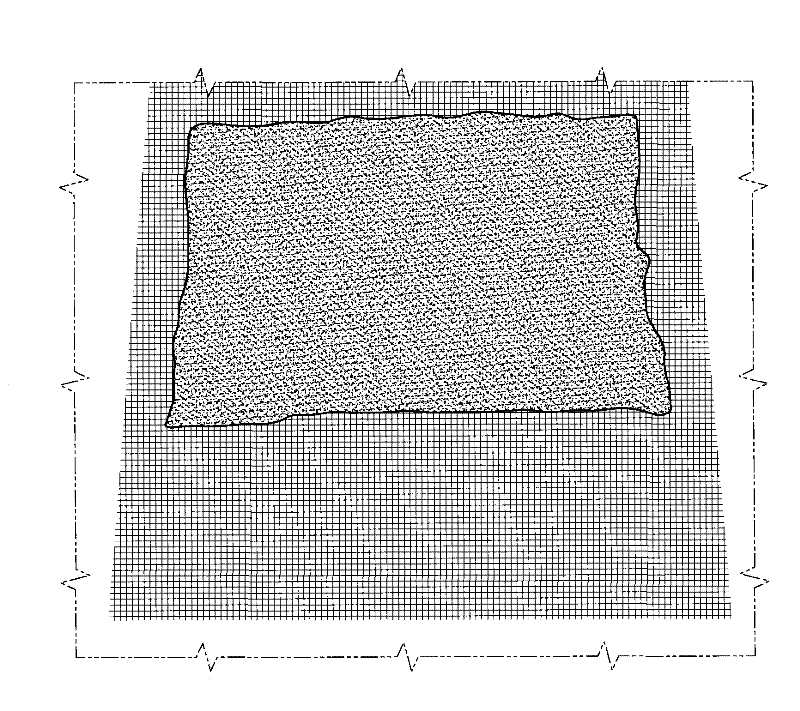

[0044] Take 35% Y-type zeolite and 65% SiO 2 After mixing, add 50% (Y-type zeolite + SiO 2 ) and 50% modifying agent were evenly mixed, and heated with 0.75M sodium hydroxide for 50 minutes by hydrothermal method to carry out the gelation process to obtain zeolite colloid, which was spread on iron grid, and then dried at 100°C for 8 Hours, calcined at 450° C. for 8 hours to prepare a zeolite with a strengthened network structure, and its silicon-aluminum ratio (Si / Al) is 17. The schematic diagram of the obtained reticulated zeolite is as figure 2 As shown, the finished product is as Figure 4 shown. Referring to Example 1, the structure-strengthened zeolite was mixed with silver nitrate and copper nitrate ion aqueous solutions with the same ratio and parameters to prepare metallic zeolite with silver and copper ion contents of 1%. The above percentages are by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com