New method for comprehensively utilizing food wastes

The technology of a kitchen waste and a new method, applied in the field of kitchen waste treatment, can solve the problems of complex fermentation control, low comprehensive utilization efficiency, etc., and achieve the effects of simple residue components, low production cost, and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

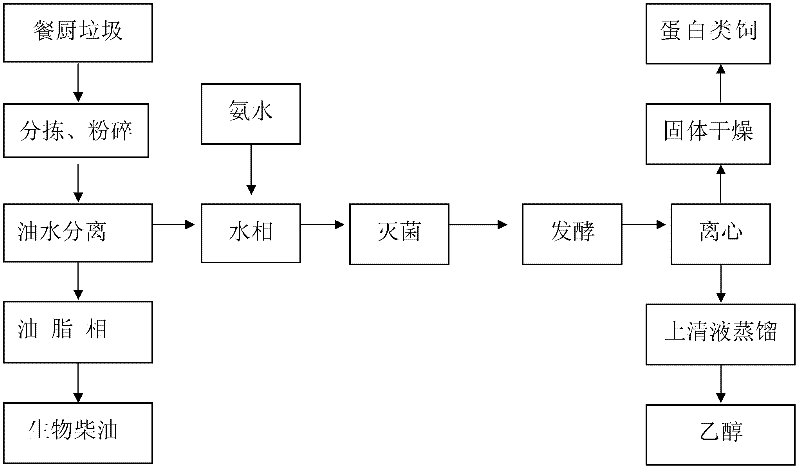

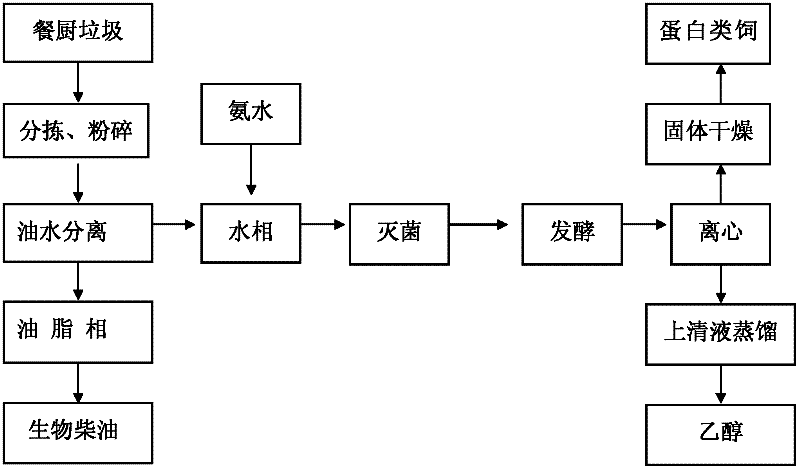

Method used

Image

Examples

Embodiment 1

[0031] Take food waste for manual sorting, sort out large bones, metal objects, plastics, ceramics and other substances that cannot be used as fermentation raw materials, and then add 3 times the volume of water to the sorted food waste and then pass it through the pulverizer Carry out crushing and beating, and then pass through the oil-water separator to separate the oil layer and the water phase.

[0032] After weighing the grease layer obtained above, add sodium methoxide according to 1% of the weight of the grease layer, and react for 1.5 hours at a temperature of 40°C to 50°C, wash twice with water, separate layers, and distill the water phase , after drying the obtained organic layer, carry out distillation to obtain biodiesel.

[0033] Add 5% ammonia solution by the weight of the water phase to the water phase obtained above, and then use ultrasonic waves to break the crystals of the cellulose in the kitchen waste. After the end, use the obtained water phase as the fer...

Embodiment 2

[0035]Take the food waste for manual sorting, and pick out the large bones, metal objects, plastics, ceramics and other substances that cannot be used as fermentation raw materials, and then add the sorted food waste to 4 times the volume of water and grind it through the pulverizer Crush, beat, and then pass through the oil-water separator to separate the oil layer and water phase.

[0036] After weighing the grease layer obtained above, add sodium methoxide according to 0.8% of the weight of the grease layer, react for 1.0 hour at a temperature of 50°C to 70°C, wash with water three times, separate layers, and distill the water phase, The obtained organic layer is dried and then distilled to obtain biodiesel.

[0037] Add 8% ammonia solution by the weight of the water phase to the water phase obtained above, and then use ultrasonic waves to break the crystals of the cellulose in the kitchen waste. After the end, use the obtained water phase as the fermentation stock solution...

Embodiment 3

[0039] Take food waste for manual sorting, sort out large bones, metal objects, plastics, ceramics and other substances that cannot be used as fermentation raw materials, and then add 5 times the volume of water to the sorted food waste and grind it through a pulverizer Crushing and beating, and then through the oil-water separator to separate the oil layer and water phase.

[0040] After weighing the grease layer obtained above, add sodium methoxide according to 1.5% of the weight of the grease layer, and react for 1.5 hours at a temperature of 50°C, wash with water three times, separate layers, distill the water phase, and obtain the After the organic layer is dried, it is distilled to obtain biodiesel.

[0041] Add 10% ammonia solution according to the weight of the water phase to the water phase obtained above, and then use ultrasonic waves to break the crystals of the cellulose in the kitchen waste. After the end, use the obtained water phase as the fermentation stock sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com