Titaniferous composition, method for forming nano particle film on ceramic or glass surface from titaniferous composition and application of titaniferous composition

A nanoparticle and composition technology, applied in the field of nanomaterials, can solve the problems of poor binding force of matrix materials and limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] The preparation steps of the titanium-containing composition are as follows (in parts by weight):

[0129] First, in a covered reactor, 4 parts of titanium tetrachloride, 2 parts of ethyl titanate, 20 parts of ethanol with a concentration of 68% by weight and 14 parts of ethylene glycol are dissolved to prepare the metal oxide precursor solution.

[0130] Then, 0.5 part of Tween 80 and 0.1 part of perfluoroalkyl polyether were dissolved in 108 parts of deionized water to prepare template solution.

[0131] Then 0.81 parts of zinc nitrate was dissolved in 10 parts of water to make a doping solution.

[0132] Finally, under the condition of normal pressure and room temperature, the template solution, the metal oxide precursor solution and the dopant solution are sequentially added into the reaction kettle, and stirred evenly.

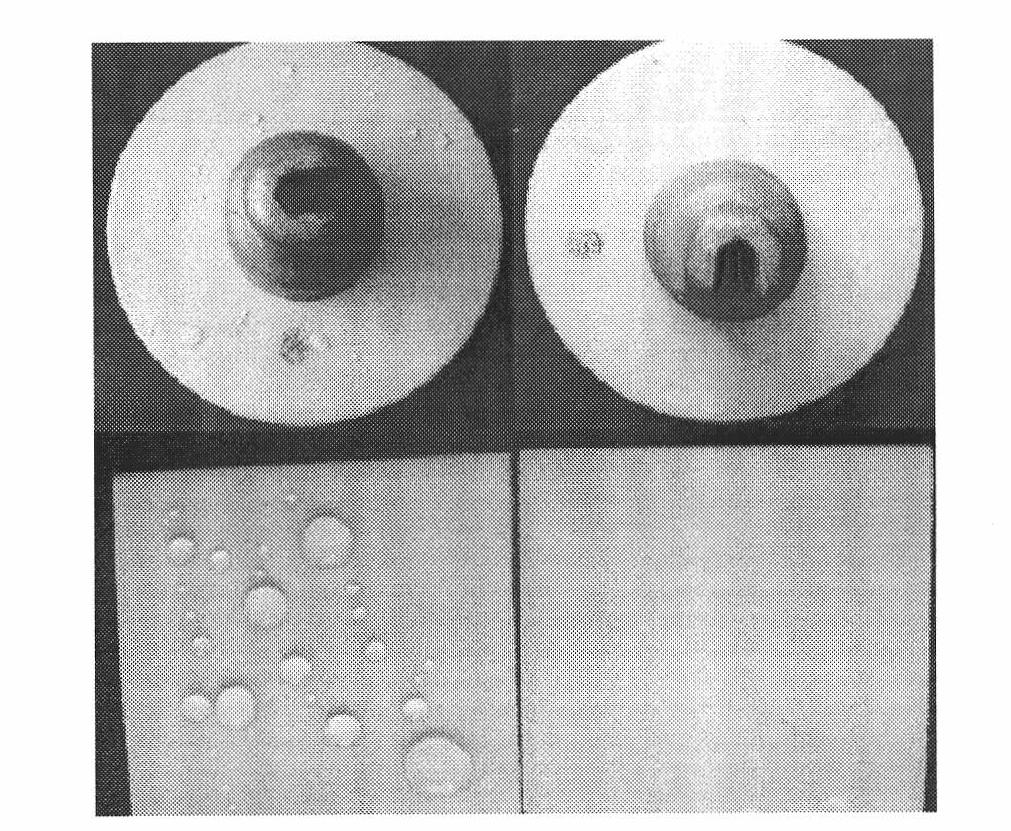

[0133] The prepared titanium-containing composition is dipped and pulled to prepare a nanoparticle film on the surface of a glass slide. The ch...

Embodiment 2

[0136] The preparation steps of the titanium-containing composition are as follows (in parts by weight):

[0137] First, in a covered reactor, 5 parts of ethyl titanate, 0.2 part of tin tetrachloride, 16 parts of ethanol with a concentration of 50% by weight and 3 parts of propylene glycol were dissolved to prepare the metal oxide precursor solution.

[0138] Then, 0.5 parts of polyvinylpyrrolidone PVP (K30) and 0.5 parts of perfluoroalkyl polyether were dissolved in 108 parts of deionized water to prepare a template solution.

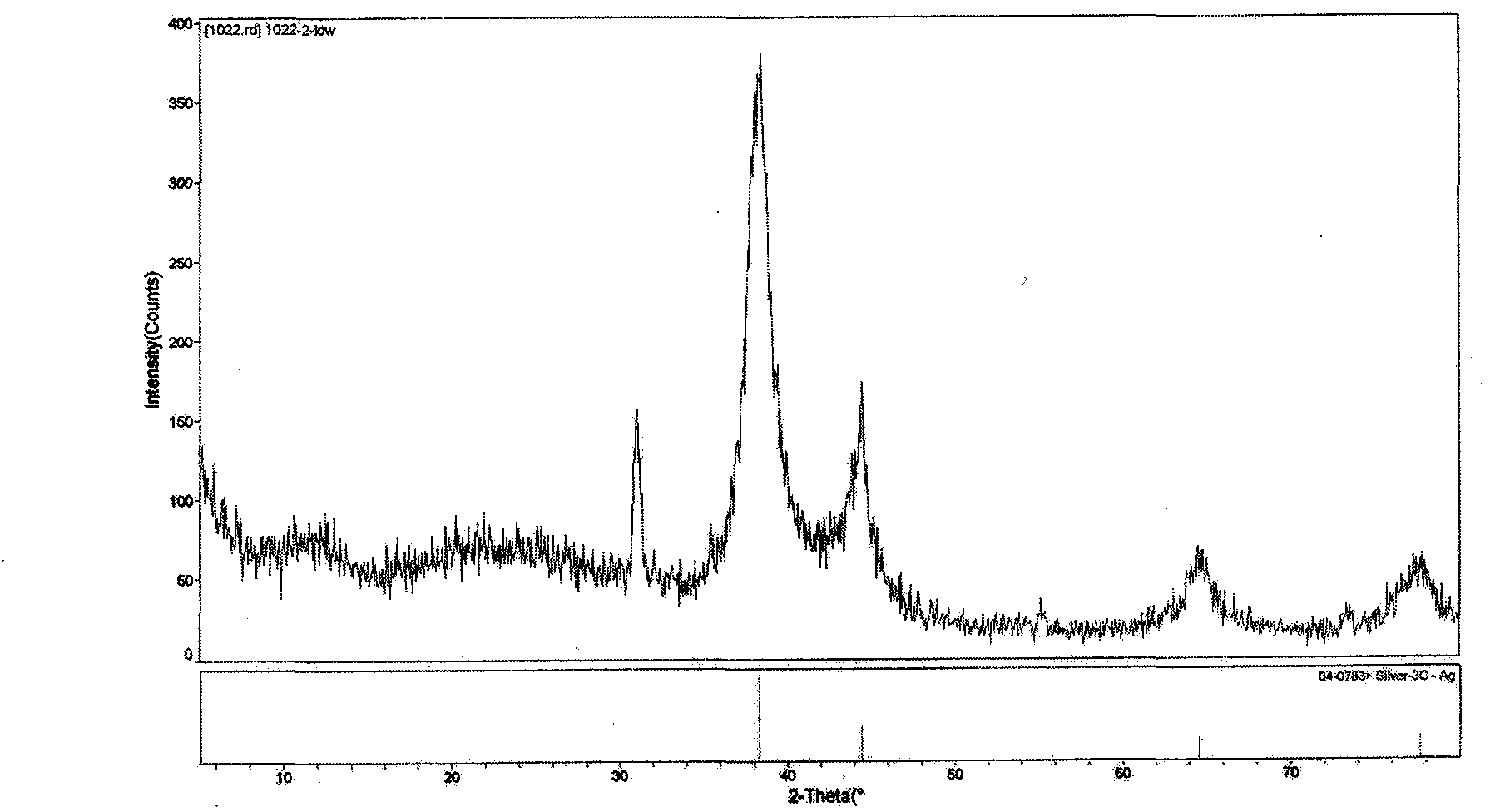

[0139] Then 0.017 parts of silver nitrate was dissolved in 10 parts of water to make a doping solution.

[0140] Finally, under the condition of normal pressure and room temperature, the template solution, the metal oxide precursor solution and the dopant solution are sequentially added into the reaction kettle, and stirred evenly.

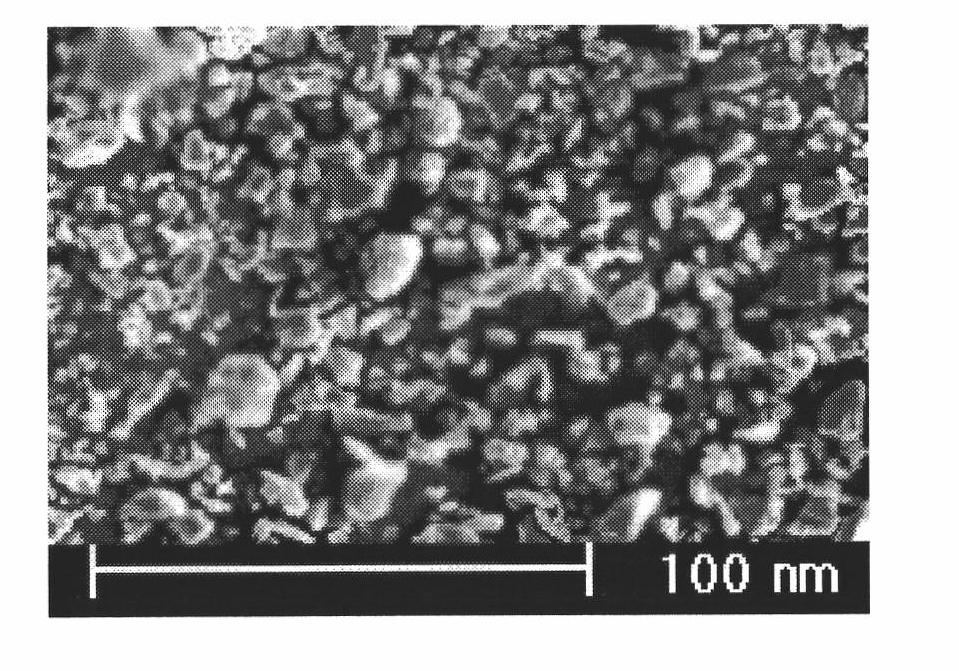

[0141] The prepared titanium-containing composition is dipped and pulled to prepare a nanoparticle film on the surface ...

Embodiment 3

[0144] The preparation steps of the titanium-containing composition are as follows (in parts by weight):

[0145] First, in a covered reactor, 8 parts of isopropyl titanate, 0.5 parts of aluminum isopropoxide, 20 parts of isopropanol and 3 parts of ethanol with a concentration of 98% by weight are dissolved to prepare the metal oxide precursor body solution.

[0146] Then, 2 parts of perfluoroalkyl polyether were dissolved in 108 parts of deionized water to prepare template solution.

[0147] Then 0.017 parts of silver nitrate and 1 part of citric acid were dissolved in 10 parts of water to make a doping solution.

[0148] Finally, under the condition of normal pressure and room temperature, the template solution, the metal oxide precursor solution and the dopant solution are sequentially added into the reaction kettle, and stirred evenly.

[0149] The same detection method is used for the glass slide and ceramic sheet treated with the titanium-containing composition, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com