Composite material of natural plant nano-fibers and metal nano-particles and preparation method thereof

A technology of metal nanoparticles and nanofibers, which is applied in the fields of plant fibers, botanical equipment and methods, nanotechnology for materials and surface science, etc., to achieve the effects of good catalytic activity, concise synthesis route, and simple route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In a 50ml one-mouth bottle, add 20ml of a suspension containing nanofibers of natural cypress (the nanofibers of natural cypress are placed in water and obtained by ultrasonic dispersion) and 10 μl of suspension containing AgNO 3 The aqueous solution obtains the mixed solution, the nanofiber of the natural cypress that contains mass fraction in the mixed solution is 0.05%, the AgNO of 0.01M 3 . Then the one-mouth bottle was placed in a water bath at 100° C. for 30 minutes to react, and the reaction product was centrifuged and freeze-dried to obtain a composite material with silver nanoparticles uniformly arranged on the surface of the nanofibers of natural cypress.

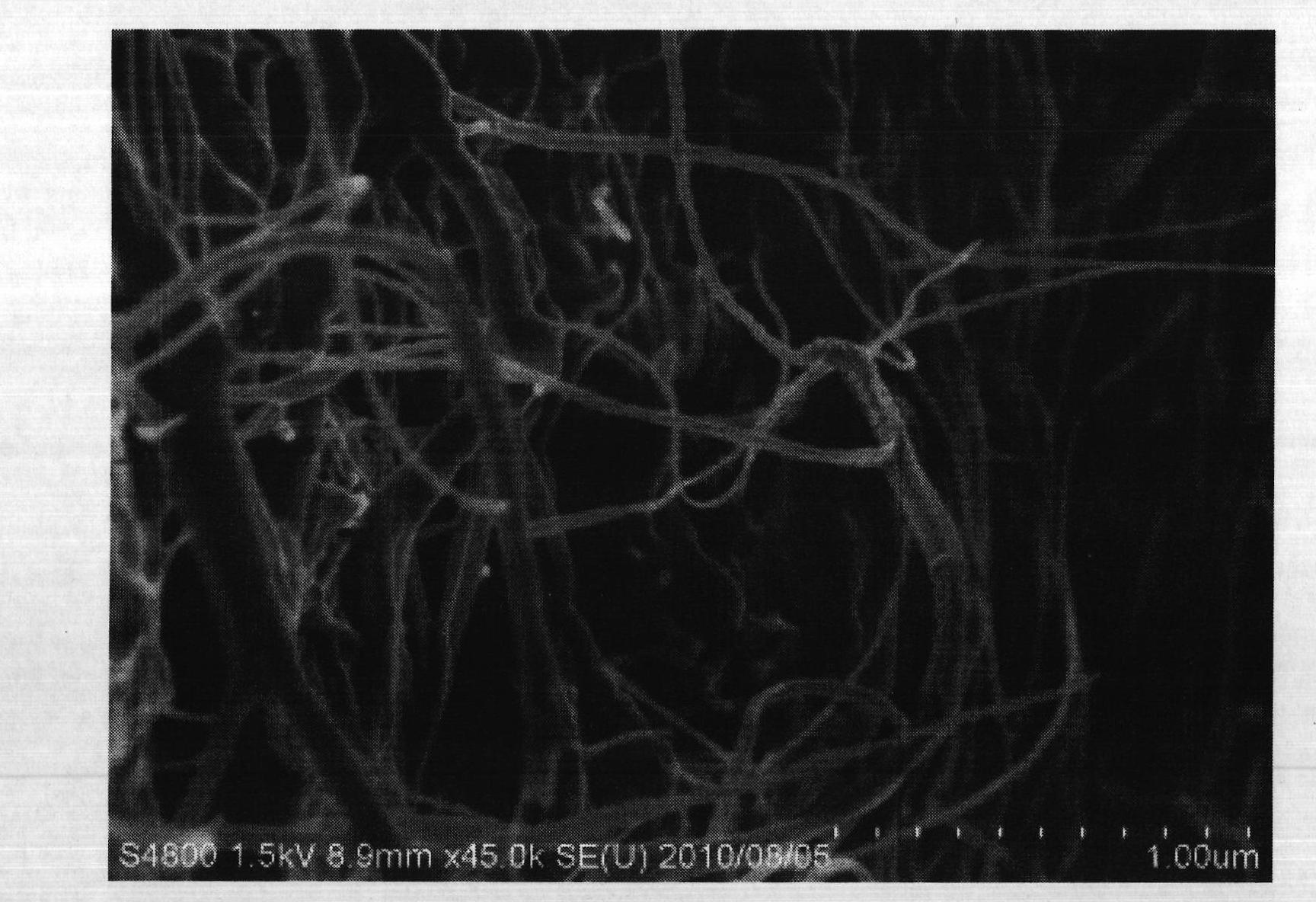

[0049] The transmission electron microscope (TEM) photograph of the nanofiber of above-mentioned natural cypress is as figure 1 As shown, it can be seen that the nanofibers of natural cypress have a diameter of 2 nm to 100 nm and a length of 1 μm to 100 μm. The resulting transmission electron microscope (...

Embodiment 2

[0051] In a 50ml one-port bottle, add 20ml of the suspension containing the nanofibers of natural cypress and the nanofibers of cedar (the nanofibers of natural cypress and the nanofibers of cedar are placed in water and obtained after ultrasonic dispersion) and 5ml containing HAuCl 4 The aqueous solution obtains mixed solution, and the mixed solution containing the nanofiber (the weight ratio of both is 1: 1) that the nanofiber of the natural cypress of 0.1% and the nanofiber of cedar tree mixes in the mixed solution, the HAuCl of 0.01M 4 . Then react at room temperature for 30 minutes, centrifuge the reaction product, and freeze-dry to obtain a composite material in which gold nanoparticles are uniformly arranged on the surface of nanofibers mixed with natural cypress nanofibers and cedar nanofibers.

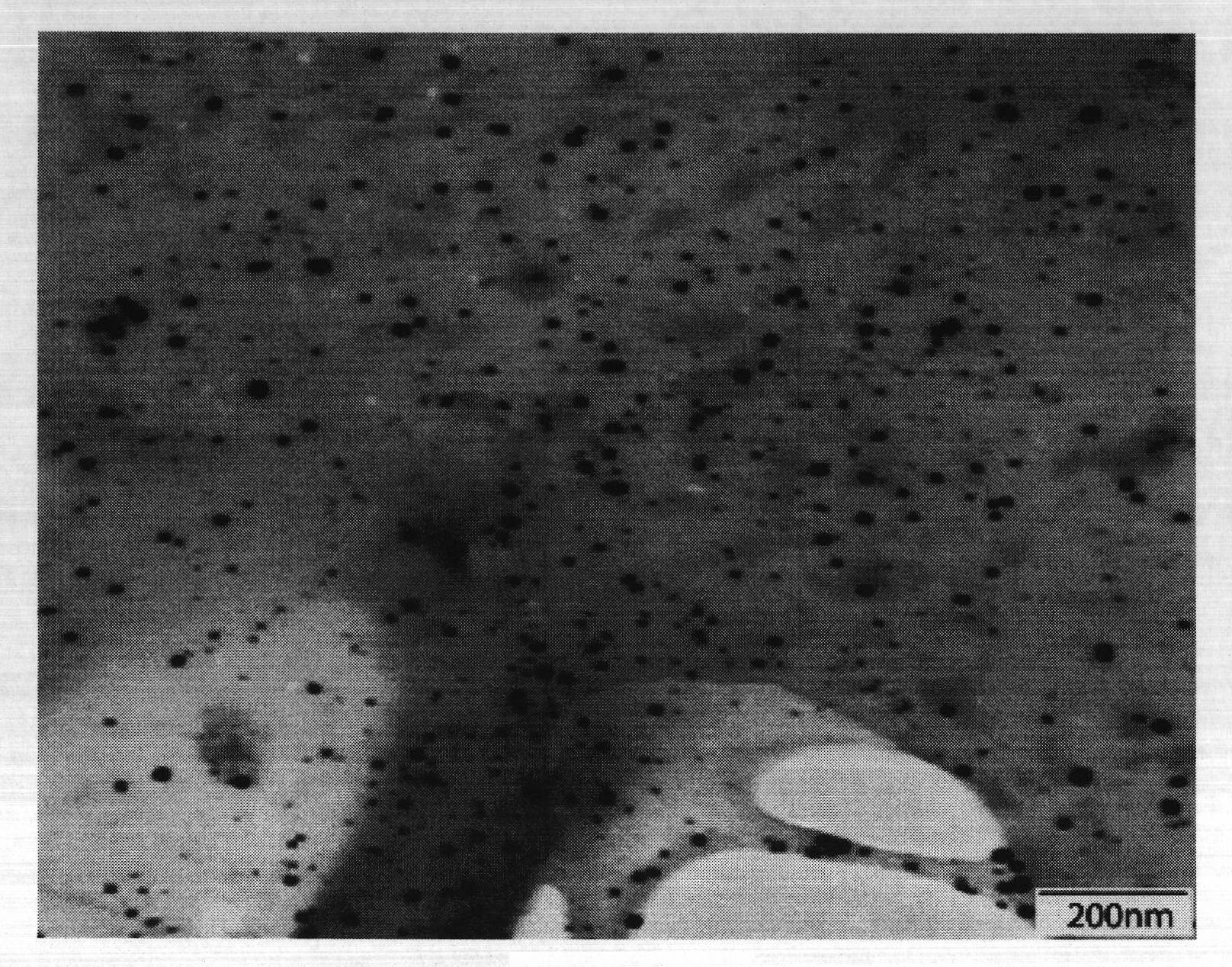

[0052] The transmission electron microscope (TEM) photograph of the composite material loaded with gold nanoparticles evenly arranged on the surface of the nanofibers of natu...

Embodiment 3

[0054] In a 50ml single-mouth bottle, add 20ml of a suspension containing nanofibers of natural cypress (the nanofibers of natural cypress are placed in water and obtained after ultrasonic dispersion), adjust the pH value of the suspension to 14 with sodium hydroxide, and then add 200 μl Contains HAuCl 4 The aqueous solution obtains the mixed solution, and the mixed solution contains the nanofibers of 0.1% natural cypress in the mixed solution, the HAuCl of 0.01M 4 . Then react at room temperature for 30 minutes, centrifuge the reaction product, and freeze-dry to obtain a composite material with gold nanoparticles evenly arranged on the surface of the nanofibers of natural cypress.

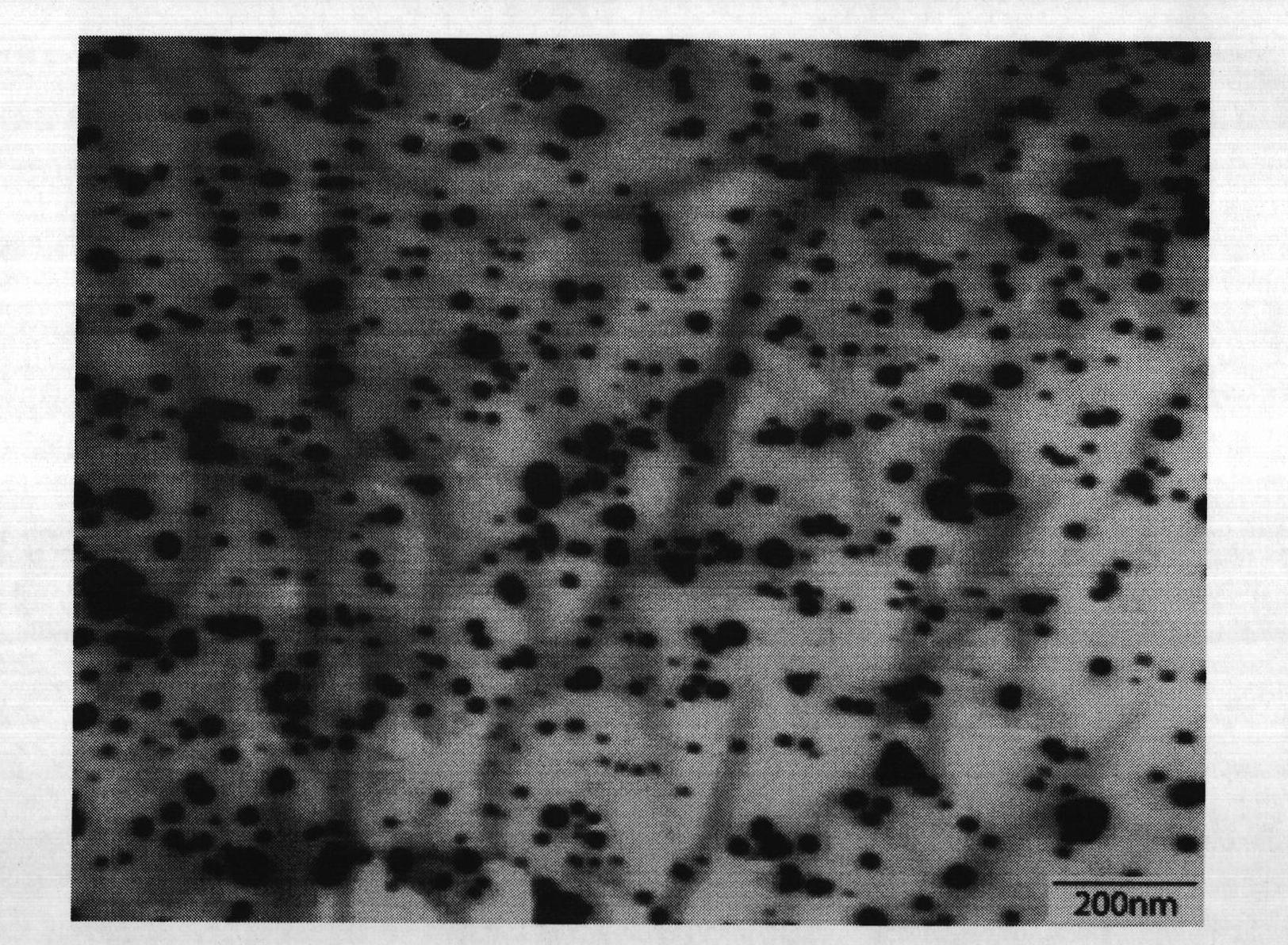

[0055] The resulting transmission electron microscope (TEM) photo of the composite material loaded with gold nanoparticles evenly arranged on the surface of the nanofibers of natural cypress is as follows: Figure 5 As shown, it can be seen that the gold nanoparticles are evenly distributed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com