Absorbent body and absorbent article

A technology for absorbers and materials, applied in the field of absorbers and absorbent articles, can solve the problems of reduced gel strength, thickened thickness, and reduced crosslinking degree of acrylic acid, so as to improve liquid absorption rate, reduce deformation, and prevent leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

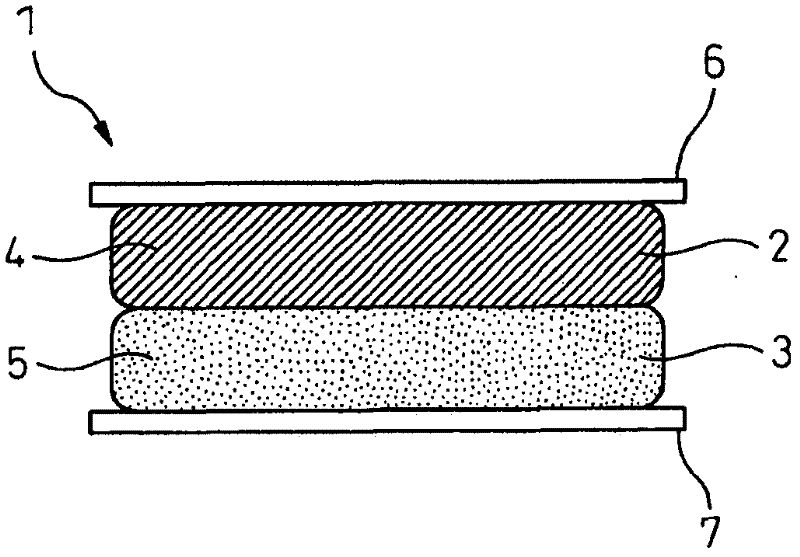

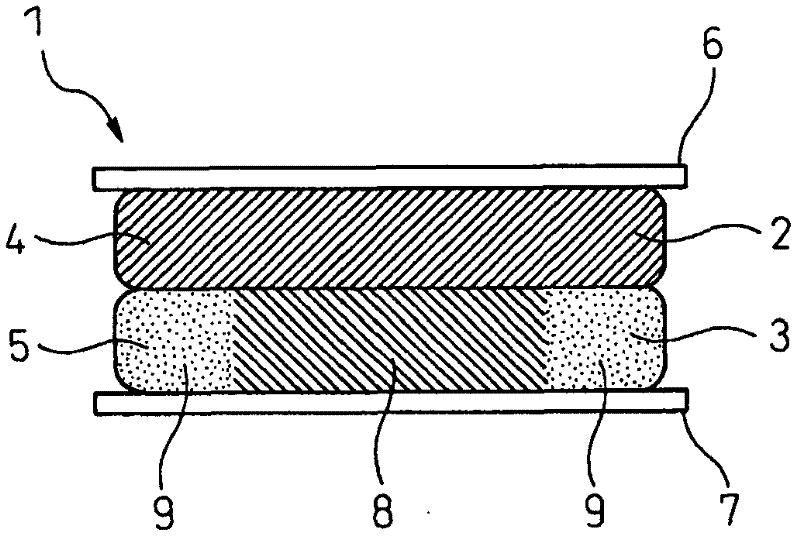

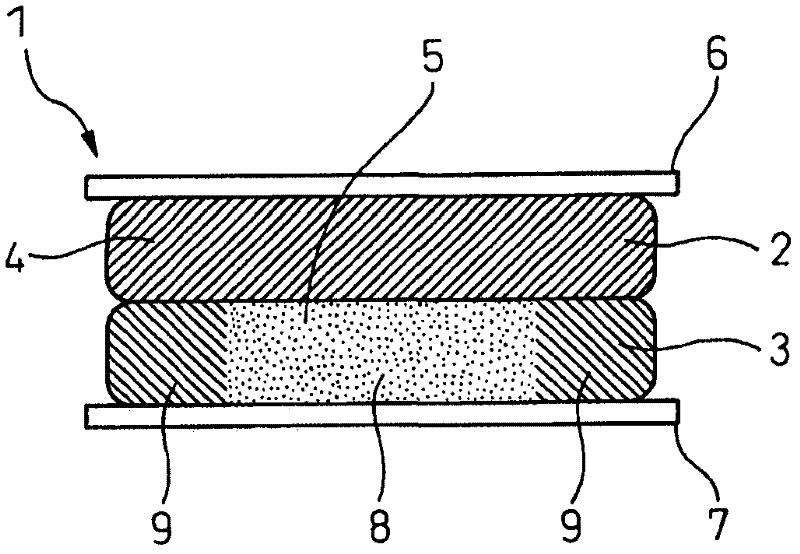

Image

Examples

preparation example 1

[0196] -Parts for the upper layer-

[0197] Materials composed of sodium alginate (manufactured by Kimica Co., Ltd., B-S) and calcium hydrogenphosphate dihydrate (manufactured by Wako Pure Chemical Industries, Ltd.) were mixed at a mass ratio of 1:1 until uniform to obtain a gelling agent. By adopting a sprayer to spray water, the above-mentioned gelling agent is fixed on the through-flow non-woven fabric (PE / PP core-sheath composite fiber, basis weight: 40g / m 2 ) on the entire face, forming the basis weight of the above-mentioned gelling agent is 160g / m 2 parts for the upper layer.

[0198] -Parts for the lower layer-

[0199] A material composed of sodium alginate (manufactured by Kimica Co., Ltd., B-S) as a tackifier was fixed on a through-flow non-woven fabric (PE / PP core-sheath composite fiber, basis weight: 40 g / m) by spraying water with a sprayer. 2 ), the basis weight of the above tackifier is 160g / m 2 parts for the lower layer.

[0200] -Preparation of absorbent ...

preparation example 2

[0203] The material for the upper layer was changed to mix sodium alginate (manufactured by Kimica Co., Ltd., B-S), calcium hydrogen phosphate dihydrate (manufactured by Wako Pure Chemical Industries, Ltd.) and glucose at a mass ratio of 1:1:1. Absorbent 2 was prepared in accordance with Preparation Example 1 except for sugar acid-δ-lactone (manufactured by Wako Pure Chemical Industries, Ltd.).

Embodiment 1 and 2

[0213] [Examples 1 and 2, Comparative Examples 1 to 3, and Reference Example 1]

[0214] The properties of absorbent bodies 1 to 6 prepared in Preparation Examples 1 and 2, Comparative Preparation Examples 1 to 3, and Reference Preparation Example 1 were evaluated. The steps are as follows.

[0215] 1) Each absorber was placed in a plastic plate (10 cm x 10 cm x 1 cm), and the thickness was measured.

[0216] 2) With the surface sheet peeled off, artificial urine (2% urea, 0.8% sodium chloride, 0.08% magnesium sulfate heptahydrate, 0.03% calcium chloride dihydrate were dissolved in ion-exchanged water To prepare) 40g evenly poured on the upper parts, let stand for 5 minutes.

[0217] 3) The surface sheet was put back on the absorber, filter paper (30 g) was placed on it, and a weight of 3.5 kg was further placed.

[0218] 4) After 3 minutes, remove the filter paper and the weight, and calculate the absorption capacity of the filter paper (moisture regain 1) based on the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com